15 December 2021

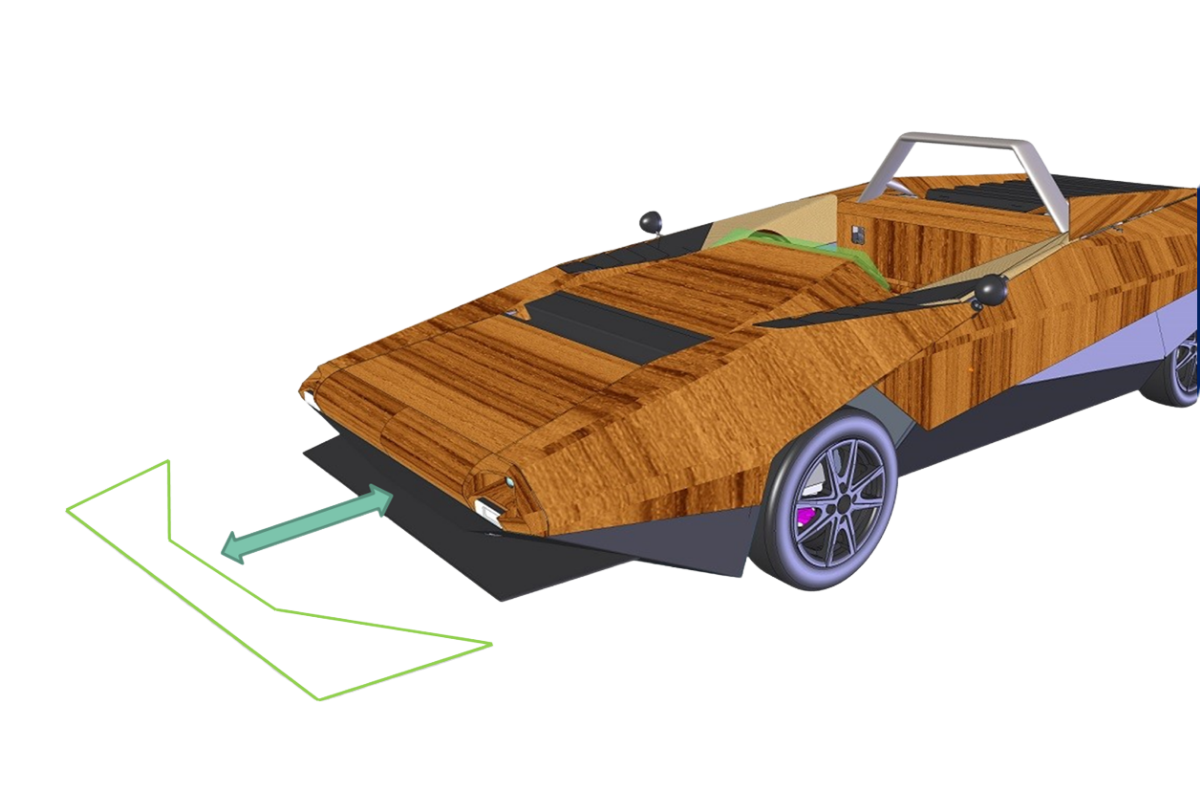

Suilven RDE Ltd, an automotive design SME, previously worked with the National Composites Centre (NCC) under Project SALSA, to explore the environmental savings and impact on performance due to the use of natural fibre composites in their automotive body panels.

Following this work and similar requests from Piper SV and Nedra, Suilven and the NCC wanted to take this a step further and assess composite material solutions that incorporate natural fibres and both bio-derived and biodegradable resin systems.

Challenge

Glass Fibre Reinforced Polyester (GFRP) is the go-to body work solution for the UK low-volume automotive industry. GFRP is derived from unsustainable natural resources and there are currently no recognised routes for end-of-life for GFRP products, other than landfill. UK low-volume manufacturers require a product that 1) can fit into existing collections and end-of-life strategies; and 2) is environmentally safe for all product that is not collected (leaked) or sent to landfill.

To start the journey towards meeting these demands for sustainable body panel solutions, the NCC launched Project SILVIA.

The challenge for Project SILVIA was to source, manufacture and test available composite materials that could potentially meet the following key requirements:

- 100% bio-sourced 100% biodegradable (e.g. compostable)

- Readily available on the market Low cost (i.e. comparable to GFRP)

- Require only simple tooling and equipment for processing

- Minimum manufacturing rate: able to process one part per day

- Possess properties for 10+ years in service (including UV resistance, impact resistance and repairability)

Innovation

Project SILVIA sourced, manufactured and tested thermoplastic comingled with natural fabric that is 100% bio-sourced and 100% biodegradable. Benchmarking these materials against GFRP laminates aimed to prove-out and provide confidence to industry that these materials represent a valid sustainable alternative for engineering applications. The project has evaluated the performance of these materials not only from a cost and technical perspective, but also accounted for their social and environmental impacts – in line with the three pillars of sustainability: people, planet and profit.

Result

Project SILVIA successfully sourced two materials, both thermoplastic, that had potential to meet the above requirements. Of these two, one was successfully manufactured and tested: Lincore PLA FF, properties for which are shown below . The manufacturing process consisted of using a heated platen press to apply a continuous clamping force to the preform, with temperatures elevated above the melt temperature of the thermoplastic PLA twill 2-by-2, [0°, 90°].

Test coupons of consolidated Lincore demonstrated similar mechanical properties to our baseline of GFRP, but interestingly, they were of a lower density and therefore have the potential to be more lightweight. These initial test results demonstrated validity of the material for use within low-volume automotive applications.

What next? The National Composites Centre aims to provide UK low-volume automotive manufacturers with the requisite data to de-risk and enable design with, and manufacture of, fully sustainable composite materials. By achieving this task, the industry can ensure future generations have access to fully sustainable transportation, both in propulsion and in the very materials that deliver it. The NCC wants to build on this initial confidence obtained in SILVIA and has therefore initiated Project ASSIST. Project ASSIST will broaden the assessment of composite materials that have the potential to meet our key requirements, and together with UK manufacturers, use them to manufacture and test standard automotive parts. They will be assessed for other factors such as durability in service (including fatigue, creep, environmental and crash behaviour) and biodegradability at end-of-life (including composting trials).

Chris Runciman, Owner of Suilven RDE Ltd, said: "The fact that competitive materials with 100% bio-source and 100% bio-end-of-life options are being actively developed is fantastic news. Composites are an enabler for low-volume automotive products, and it is extremely encouraging to know that more sustainable materials options will be available soon."