Engineering talent - we’re going to need more of it

Engineering talent is the edge and we’re going to need more of it. By Claire Arbery, Head of Strategic Workforce Development Solutions, NCC.

The tools we use to design and build things are changing fast. AI, automation, new materials, digital platforms - these aren’t future challenges. They’re already shaping how we make everything from aircraft components to turbine blades.

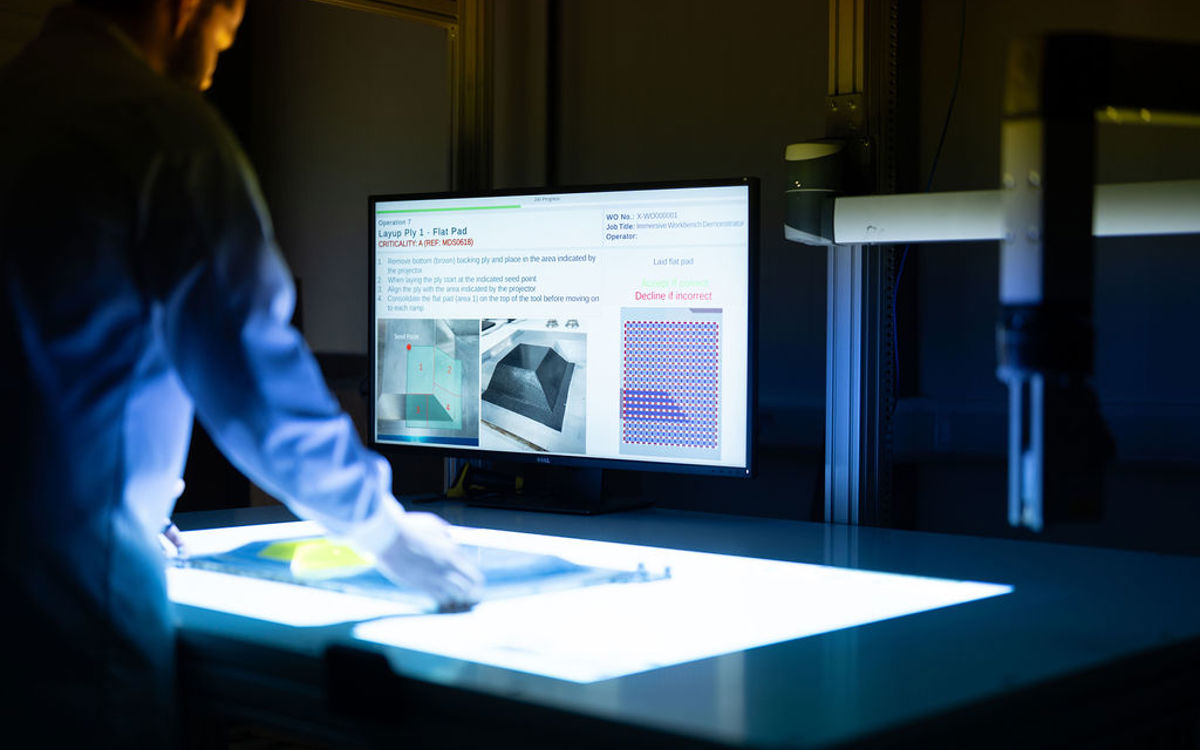

At NCC- innovating for Industry, we’re using these technologies every day. We’re running digital twins on live infrastructure. Using AI to improve resin flow in composite parts. Training engineers to spot defects before they happen. But none of this happens without people. Skilled people. Teams who understand how to combine physical materials with digital tools - and how to apply engineering judgement in real environments.

The UK has no shortage of talent. But we do need to be honest - we haven’t always built the systems to support it well.

We’ve leaned heavily on academic routes - now we need balance

For a long time, the UK’s skills system has tilted toward academic achievement, and a thirst for graduates. We’ve got a world-leading university sector, but we haven’t always given the same attention or status to vocational routes - especially in technical industries.

That’s changed. Colleges, and particularly those that are part of the National Network of Institutes of Technology, are modernised with access to industry specified equipment. The Department for Education is backing technical qualifications like T Levels and Higher Technical Qualifications, building our technical capabilities back. Local Skills Improvement Plans are giving regions more control. There’s good progress.

But culture moves far slower than policy. Too often, technical skills are still seen as second tier. That’s not just unfair - it’s risky. Because the future of manufacturing needs people who can do both - understand the theory and apply it in practice.

AI will challenge assumptions about what skills matter

Some of the jobs changing fastest aren’t on the factory floor - they’re at the desk. Planning, scheduling, design iteration, even simulation, all are being reshaped by automation and AI. That’s putting pressure on white-collar roles we once thought were insulated.

What’s becoming more valuable is the ability to work across boundaries. To use digital tools but also understand when they’ve got it wrong. To combine process knowledge with design intent. To spot patterns that an algorithm might miss.

This is where experienced engineers and technicians shine. The people who’ve built parts, solved production problems, worked with machines and materials - and learned what works. That kind of judgement is hard to automate. That ear that can spot a machine is about to fail, that smell that shows a compound hasn’t mixed correctly, these are essential when we’re pushing the boundaries of performance and reliability.

Engineering isn’t one route - it’s a whole system of expertise

At NCC, we see engineering as something broad and layered. You might come through an apprenticeship, a degree, a career in another sector. What matters is how you think, how you solve problems, and how you work with others.

We work with all kinds of people - from new apprentices to seasoned engineers. Some are learning composites for the first time. Others are figuring out how to use digital twins in sectors that have never had access to live simulation. What they all need is support, real-world examples, and space to develop capability over time.

We also know that the best results come when teams include a mix of backgrounds. People who’ve done things differently. People who’ve worked in energy, defence, aerospace, construction. People who know the material - and people who ask the right questions.

What we’re doing to support skills

We’re not just talking about the skills gap - we’re working with partners to close it:

With Colleges, we’re building new training for the energy and defence sectors – giving College students access to composite manufacturing, automation and sustainability tools they’ll actually see in industry.

With SMEs across the UK, we’re helping upskill workforces so they can adopt digital tools confidently - from AI-assisted scanning to in-process data capture.

In our training environments, we’re embedding access to live digital twins, AI systems and simulation data - so learners can work with the same platforms used in our R&D programmes.

For mid-career workers, we’re supporting transition - including veterans and those from other sectors - building on what they know while helping them grow into new technologies.

It’s not about replacement. It’s about building on strengths. And giving people the time and tools to adapt well.

Skills are infrastructure - not admin

We talk a lot about productivity, sovereign capability, net zero. But none of it happens without people.

Skills are often treated as an HR problem or a policy category. In reality, they’re national infrastructure. Without a steady supply of skilled, confident engineers and technicians, we can’t build anything else.

That means consistent investment, clear pathways, and better visibility for technical careers. And it means backing the organisations already doing this work - from colleges and employers to training providers and Catapults.

Let’s move with the tech - and take people with us

There’s no shortage of potential. We see it every day - in apprentices picking up digital tools, in SMEs embracing automation, in engineers combining composite know-how with AI workflows. But the technologies will keep moving. The question is whether we move fast enough to keep up - and whether our systems support the people doing the hard work of adaptation.

Whether you’re building supply chain resilience, developing new capabilities, or training the next generation of engineers — we’re ready to help.