Innovation in manufacturing often comes through strategic collaboration. And so it was when NCC and aerospace leader, Leonardo in the UK, joined forces to develop an “Immersive Workbench” to transform how complex aerospace components are produced.

Challenge

Producing high-precision composite components requires operators with years of hands-on experience to achieve the exacting standards needed in aerospace manufacturing. When manufacturing components with intricate geometries like rotor blades, there's virtually no margin for error.

What’s more, traditional manufacturing instructions can be misinterpreted and rely heavily on experienced operators for both production and quality control. This creates variability in the manufacturing process, which in turn makes scaling production - while maintaining impeccable quality standards - an even bigger challenge.

Innovation

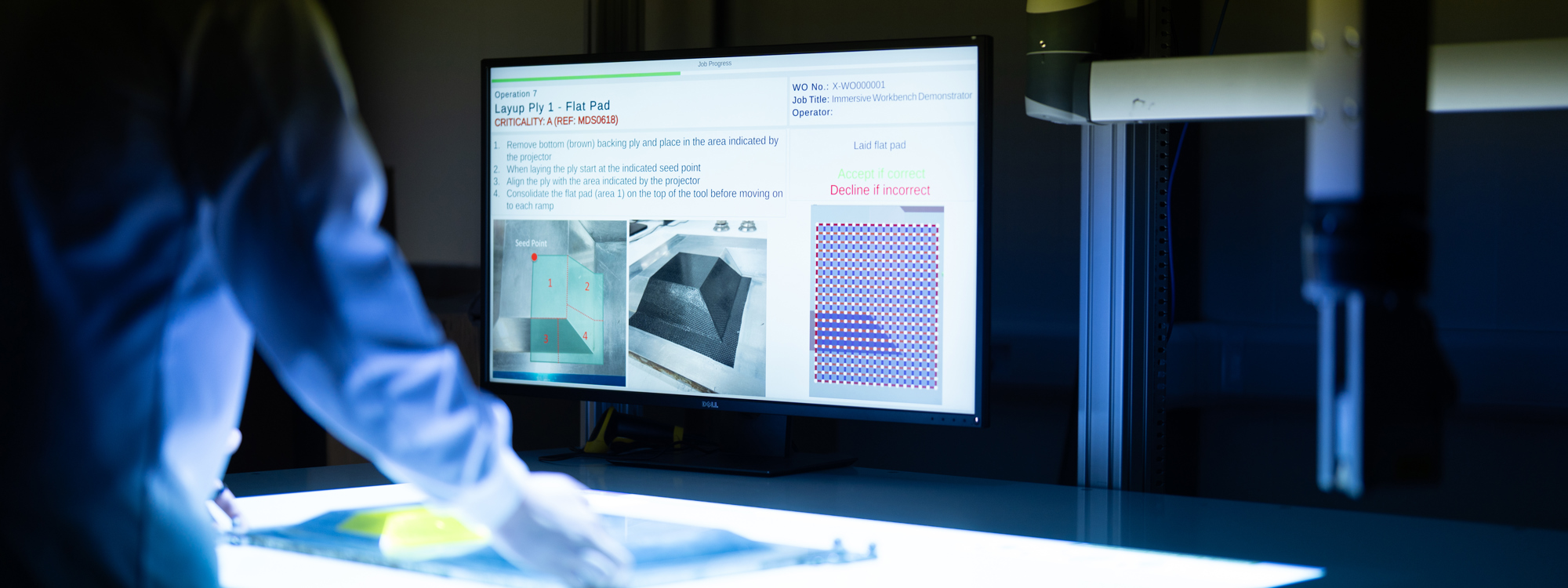

Working closely with Leonardo, experts at NCC have developed a ground-breaking 'Immersive Workbench', which represents a significant leap forward in manufacturing technology. The system integrates overhead projectors - which provide precise visual instructions directly onto components - with an OptiTrack motion capture system that continuously monitors tool positioning. A Leap Motion controller enables hands-free operation, while a set of digital cameras document each process step to create a comprehensive digital passport.

NCC also incorporated advanced laser profile scanning for real-time, in-process quality control, with the entire system managed by custom software specifically designed to handle complex 3D geometries. The combined capabilities of the Immersive Workbench bridge the gap between digital design and physical manufacturing, enabling a level of precision and consistency not previously possible.

Impact

This technology is set to reshape composite manufacturing. Not only by addressing long-standing quality-control challenges, but also by opening up new possibilities for future developments. It’s also helping to bridge the skills gap between seasoned and new operators, allowing those with less experience to achieve the same high standards.

Unlike traditional post-process inspection, the shift to real-time, in-process verification means it’s possible to identify issues before they become problems, while standardised digital work instructions ensure every operator works in the same way, every time.

Next Steps

The system is ready for what's coming next. It supports digital twins and adaptive process control, making it Industry 4.0-ready. The modular design also makes it easy to extend or add new features like advanced laser-projection systems, or other quality control devices, as technology and manufacturing processes evolve.

Usman Sikander, Technology & Innovation UK, Leonardo, said:

“Collaborating with NCC has assisted Leonardo in developing new technologies to improve efficiency and solve complex problems through innovation. We continue to explore the possibilities of revolutionary digital technologies with NCC, advancing our next-generation manufacturing to enable greater transparency, sustainability, and ultimately a more secure future.”

Simon Groves, Immersive Operations Expert, NCC, said:

"Working closely with Leonardo has allowed us to push the boundaries in composite manufacturing. By combining their industry expertise with our technical capabilities, we've created a solution that addresses real manufacturing challenges, while setting new standards for the future."

If you'd like to explore how an immersive workbench could support your business needs, reach out to our dedicated services team.