Driving change towards more sustainable pathways for processing end-of-life wind turbine blades is a key enabler to UK’s net zero ambitions. Demonstrating the vital work of the SusWIND programme, NCC’s Tom Andrews and Jessica Harrison highlight how addressing single-use plastic waste from wind turbine blades alone could divert at least a fifth of total waste burden from landfill and incineration.

The process to manufacture a wind turbine blade (WTB) generates a significant quantity of production waste. It is predicted that production waste will be 23% higher that end-of-life waste for UK wind farms up to 2045. Rightly, there have been increasing efforts to find sustainable solutions for composites at end-of-life production waste associated with however there is less discussion about how to manage the waste generated during their production.

Given the scale of production waste it is a problem that should demand attention. Primarily the waste consists of off-cut materials that are not used in the final part as well as auxiliary materials which aid the manufacturing process. These materials are largely single use plastics and so cause a significant waste burden. After use they can be damaged or contaminated, and are a complex mix of different materials, posing a challenge to reuse or recycle. Therefore, the final destination for the majority of this waste is to landfill or an incinerator.

Data driven approach

Our manufacturing model indicates that for each WTB produced a quantity of waste equivalent to 29% of the total blade mass is generated. This is incompatible with the aim of blade manufacturers to achieve zero waste manufacturing within the next 20 years. When this is extrapolated across the UK wind farm portfolio, it is predicted that 290 kt of production waste associated with UK installed WTBs will be generated by 2045. This is 23% greater than the total WTB end-of-life waste predicted for the UK over the same time period. Whilst this production waste will be spread over manufacturing sites across Europe as well as the UK it is clearly a challenge that needs to be addressed.

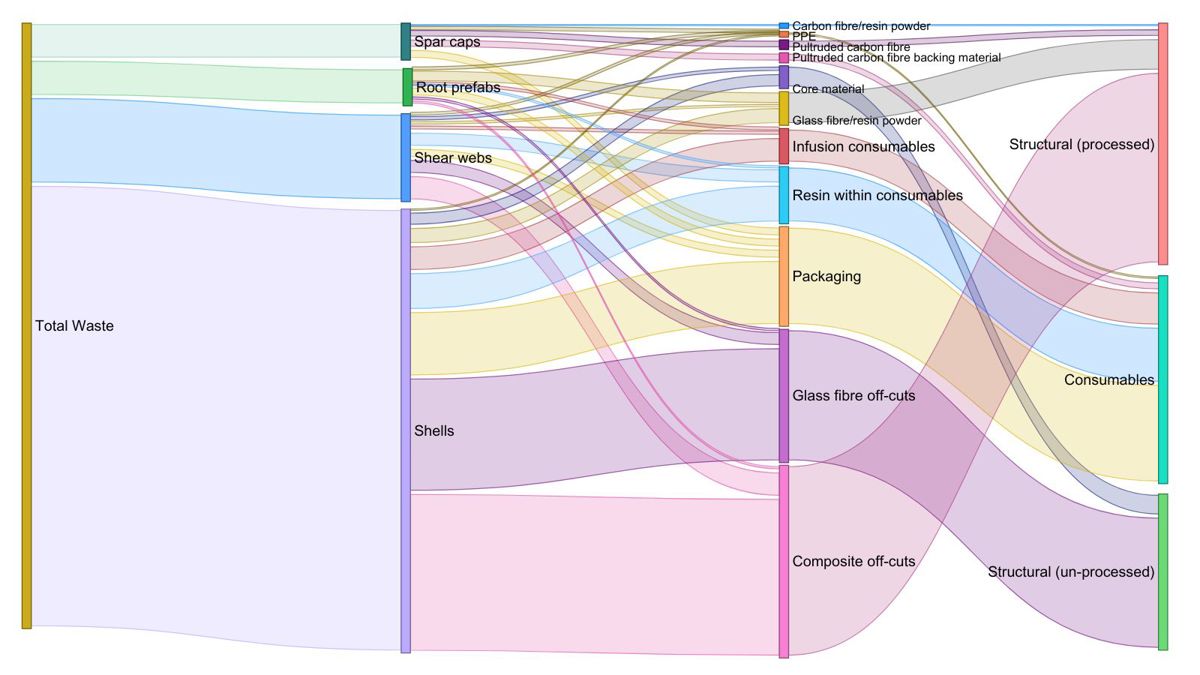

Figure 1 shows how the total waste can be broken down into the waste associated with each of the four main components of a wind turbine blade – The shell, shear webs, roots and spar caps. This waste can be broadly summarised into three main groups. One third is off-cuts of composite material, this is structurally equivalent to end-of-life composite waste. Here there is an opportunity to incorporate production composite waste into the growing mechanical recycling supply chain for end-of-life blades. The second third is made up of single use consumable materials. These are plastic components such as tubing and films that aid the manufacturing process. Embedded within these consumables is cured resin which prevents their reuse and makes them a challenge to recycle. The final third is composed of other structural materials such as powders generated during blade finishing activities, glass fibre fabric off-cuts and plastic foam off-cuts.

Waste utilisation solutions

Gathering this fidelity of data has enabled meaningful engagement with the waste handling supply chain to demonstrate effective utilisation of production waste. Four demonstration trials have been conducted to highlight what could be done with this waste:

i. Pyrolysis of consumable waste into oil and gas.

ii. Mechanical recycling of consumable waste and compression moulding into new products.

iii. Cleaning, repairing and reuse of backing materials.

iv. Reuse of powders as fillers materials in other products.

All trials were at laboratory scale but if these solutions could be sufficiently scaled to use all the relevant waste materials then 22% of the total waste burden could be diverted away from landfill and incineration. However scale, security of supply and demonstrating a market pull remain as key challenges to proving the economic viability of these methods and incentivising the supply chain to utilise the materials.

Wider challenge

This waste is not unique to wind turbine manufacture, it is a challenge acutely felt across many composite using sectors. There is considerable overlap between the waste produced in other sectors, such as marine, construction and aerospace, and the waste generated during WTB production. As has been the case with end-of-life composite waste, collaboration should be sought between manufacturers to address the common challenge of utilising production waste. Coordinated efforts are required to produce a robust supply of waste materials of sufficient scale to incentivise the waste handling industry.

Collaboration to tackle production waste will be crucial

Tackling production waste is a complex problem. The range of different waste materials generated during composite manufacturing means a system to maximise utilisation of all waste materials will require multiple technologies and supply chains. At present there are considerable gaps in the available solutions for full waste utilisation. It is going to require collaboration between composite manufacturers to address the range of different solutions required to move towards eliminating waste from manufacturing.

What we are doing:

- Modelling how increases in UK-based production of wind turbine blades and composite turbine towers will impact waste quantities.

- Incorporating geographical information into the WTB model to identify manufacturing hotspots and indicate where waste handling infrastructure should be targeted.

- Expansion of modelling to other composite sectors to feed into ongoing cross-sector circularity work and highlight areas for cross-sector collaboration.

What industry can do:

Key to this work has been data provided from stakeholders across the wind sector, as we expand this work we are actively seeking involvement from a wide range of composite manufacturers to build a picture of UK composite production waste.

Express your interest to get involved in the SusWIND programme by clicking the link below to contact Energy experts.

About the authors

Tom Andrews is an Advanced Research Engineer at NCC. His work focuses on developing data-driven methodologies to support strategic decision-making across the advanced materials sector. He has worked as a researcher to develop new material solutions which enable sustainable, low-carbon supply chains. Through programmes like SusWIND, Tom is advancing approaches to tackle waste and embed circularity into the manufacture of composite structures.

Jessica Harrison is a Research Engineer in the High Volume Manufacturing Team at NCC, and whose experience spans thermoplastic composite manufacturing, composite manufacturing using recycled materials and the application of IoT-enabled digital technologies. Combining these focuses, Jess' expertise lies in reducing the environmental impact of composite manufacturing.

SusWIND, by NCC in partnership with the Offshore Renewable Energy Catapult, is a joint industry programme advancing a circular economy for large structure composites by driving innovation in recycling and sustainable supply chains.