NCC and the Centre of Expertise in Advanced Materials and Sustainability (CEAMS) share an ambition to enhance carbon fibre sustainability by developing circular supply chains for this critical material.

The CEAMS consortium has achieved a world-first demonstration of manufacturing across multiple advanced technologies using recycled continuous carbon fibre (rCCF). The project demonstrated rCCF as a feasible substitute for virgin fibre in high-performance applications, with comparable processability and strength.

The project won the ‘Sustainability: Circularity’ Award at the 2025 Composites UK Industry Awards.

Challenge

In 2024, NCC, Cygnet Texkimp, and B&M Longworth successfully reclaimed continuous carbon fibres and recycled the material to manufacture of a pressure vessel.

Further innovations from NCC within the CEAMS consortium have removed key barriers to the adoption of recycled carbon fibre as a substitute for virgin fibres. This includes the development of new digital quality assurance and validation capabilities to help industry use reclaimed fibres with confidence.

However, recycled continuous carbon fibre is still a novel material. The challenge remained to demonstrate that it can be processed using the same methods as virgin fibres – and give the resulting products the same level of performance.

Solution

To demonstrate that recycled carbon fibre can be used as a direct substitute for virgin material - with the same processability and manufacturability - the CEAMS consortium successfully manufactured a range of second life demonstrators using advanced processes.

This collaborative project harnessed manufacturing expertise from NCC, AMRC, the Henry Royce Institute at the University of Manchester, the University of Nottingham, Ulster University, and industrial partners Moi Composites and Cygnet Texkimp. This is the first time continuous recycled carbon fibre has been used for:

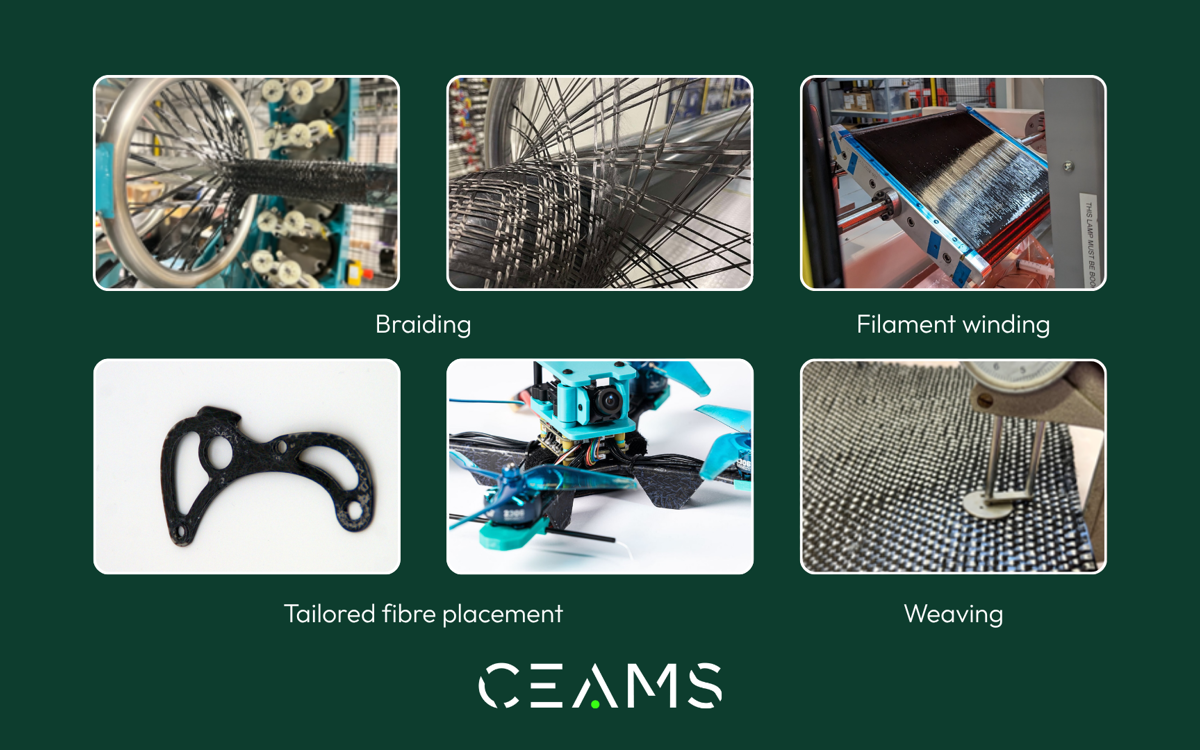

• 2D/3D weaving (AMRC, Ulster University)

• Tailored fibre placement (NCC)

• Braiding (NCC, Henry Royce Institute at the University of Manchester, University of Nottingham)

• Filament winding (NCC, Cygnet Texkimp)

• 3D Printing (Moi Composites)

Innovation

These successful trials demonstrate the viability of using recycled carbon fibre for high value applications: 2D/3D woven materials are used extensively in the manufacture of complex automotive and aerospace parts, industries which also rely on parts manufactured using braiding and tailored fibre placement. Filament winding is used in the manufacture of hydrogen pressure vessels.

Crucially, mechanical performance testing further supported the future viability of using recycled carbon fibre for structural applications, particularly in cost-sensitive sectors seeking sustainability.

Impact

By demonstrating that continuous recycled fibres can achieve performance comparable to virgin carbon fibre composites, NCC and CEAMS have established a critical pathway for integrating recycled fibres into high-performance applications. The innovation is another significant step towards creating long-term industrial and market demand for recycled continuous fibres.

Next steps

A recently announced extension to the CEAMS programme will allow NCC and CEAMS to continue to develop technologies for industrial adoption and supply chain creation, aligned with national strategies around advanced materials.

Further work on recycling of continuous carbon fibre will focus on:

• Optimising the fibre recovery process

• Building on existing breakthroughs on fibre verification

• Surface treatment and sizing to improve processability and performance

• Manufacture of additional second life demonstrators

Industrial organisations interested in exploring the use of recycled continuous carbon fibre in their existing processes and products are invited to get in touch with NCC.

CEAMS invites industry partners, research institutions, and government stakeholders to engage with the initiative, contribute to the advancement of sustainable materials, and explore opportunities for collaboration.