Bristol’s Actuation Lab secure key investment and take up residence at the NCC

Actuation Lab is rethinking industrial hardware to increase the reliability and reduce the environmental impact of mechanised industries. The company was spun out from the University of Bristol by three engineering academics who had the drive to commercialise their mechanical innovation, the Callimorph® actuator. The Callimorph® is a device that is designed to keep machines moving without succumbing to corrosion, thus preventing the crippling costs associated with unplanned downtime in the energy, marine and mining industries.

Following a significant recent investment, the award-winning company has taken up residence at Bristol’s National Composites Centre (NCC). The NCC provides access to some of the most advanced composite manufacturing capabilities in the world, so this move will significantly bolster Actuation Lab’s R&D activities and foster an exciting stage of business development.

Simon Bates, CEO at Actuation Lab said:

“The NCC is absolutely the right place for Actuation Lab to live and grow from for the next 18 months. As well as having our own secure lab space on site, the NCC have partnered with us on a pivotal Innovate UK funded project, which will see our Callimorph® actuator rapidly progress towards a marketable product.”

Leah Rider, Head of SME delivery at the NCC commented:

“We are delighted to have Actuation Lab here at the NCC, and we are working with them to provide facilities they need to support them at this important time in their development. SMEs are such an important part of the UK industry, and we want to help as many as possible take advantage of the many benefits composite materials can offer, including giving them the support to test and develop their innovations on-site at our Bristol facility."

Actuation Lab is now hiring.

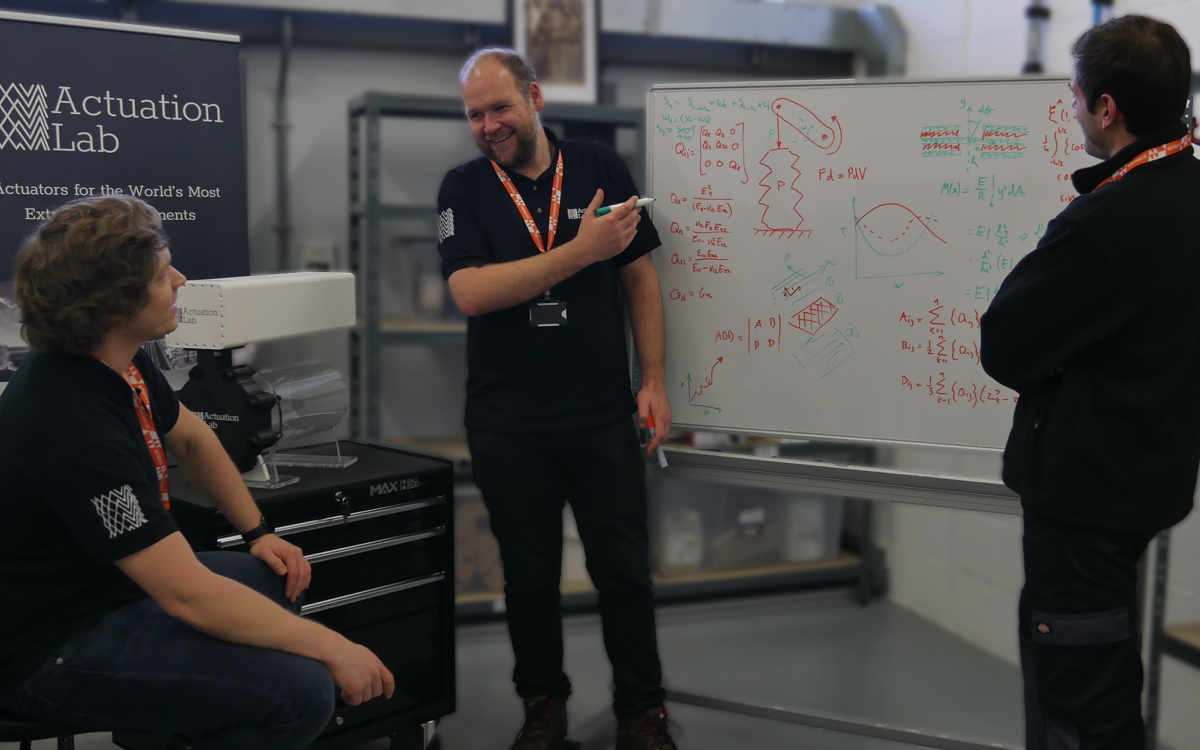

Pictured left - right: Dr Simon Bates, CEO; Dr Michael Dicker, CTO and Dr Tom Llewellyn Jones, Head of R&D.