Digital Engineering Technology & Innovation (DETI) funding has enabled Gary to optimise the technology over the past two years.

The weakest link

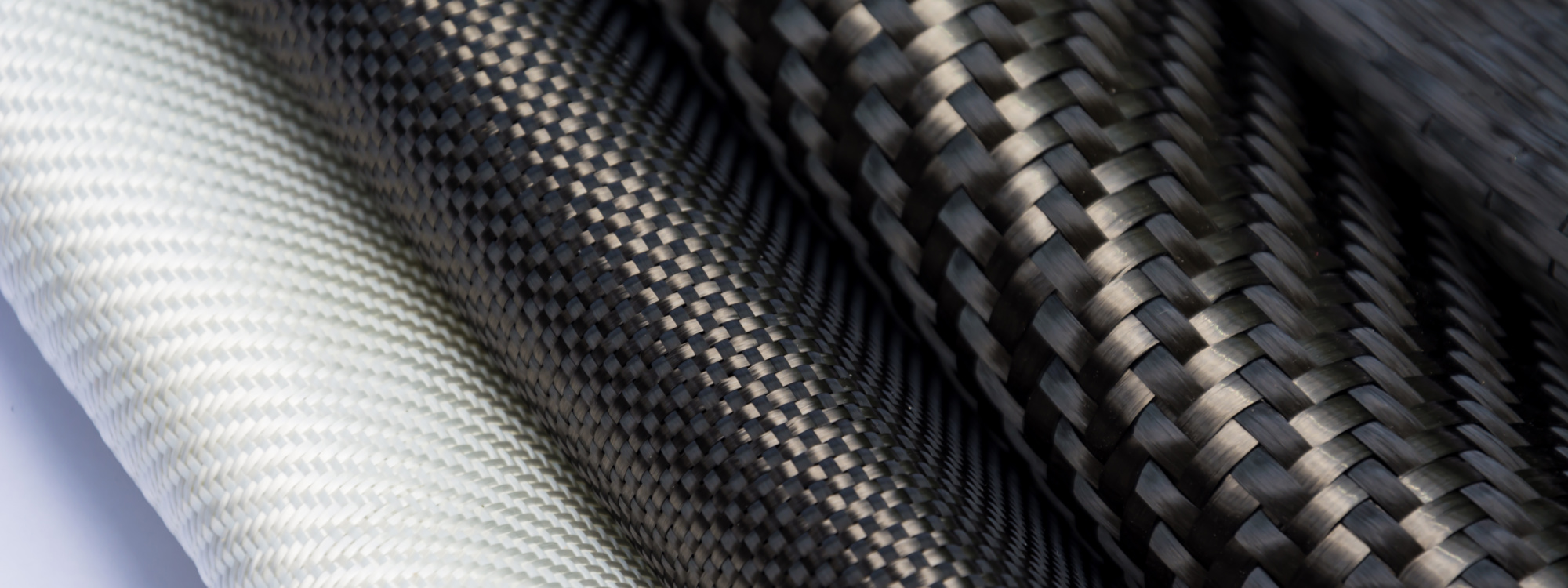

Composite material strength lies in the uniform pattern of either unidirectional or interwoven carbon fibres lying undisturbed in resin. But any composite component is only as strong as its weakest link, and weaknesses caused by fibre misalignment or gaps is a common problem in composite manufacture.

The dark, shiny nature of composite materials makes defects tricky to spot using visualisation techniques based on traditional camera technology. The current industry standard is to perform time consuming and eye straining manual inspections to ensure the safety of components, particularly those destined for applications in the aerospace industry.

Gary is utilising a different type of visualisation technique to identify the problem areas.