New seat to power GB Paracanoeist in Paris 2024

Early career engineers at NCC, part of the High Value Manufacturing Catapult, have successfully pushed off on the initial design and manufacture of an optimised paracanoe seat. The final part is set to enable a competitive edge for paralympic canoe champion Emma Wiggs MBE’s upcoming event in Paris 2024.

Background

Emma won the first ever Paralympic gold medal in the Women’s Va’a Single 200m (VL2) at Tokyo 2020 – a new discipline to the Paralympic Games. She was powered by a customised paddle designed and manufactured by NCC in collaboration with the Manufacturing Technology Centre (MTC). As victory in elite events often hinge on razor-thin margins, Emma revisited NCC for support towards improving her paracanoe seat ahead of Paris.

Challenge

Each athlete demands different requirements from their adaptive equipment. For Emma to go faster, engineering experts had to decrease the seat’s weight while enabling a more efficient transfer of power to the boat. The project demanded a race against time to ensure the ultimate seat made the cut for Emma’s rigorous pre-Game training.

Innovation

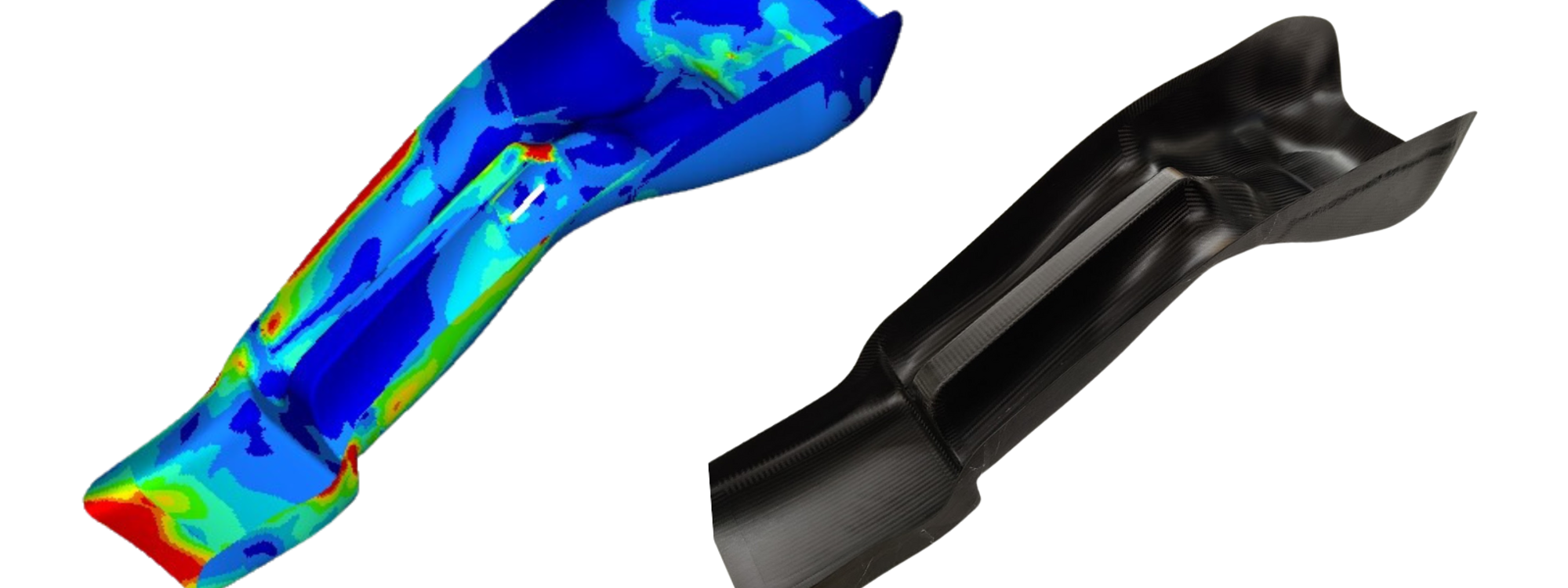

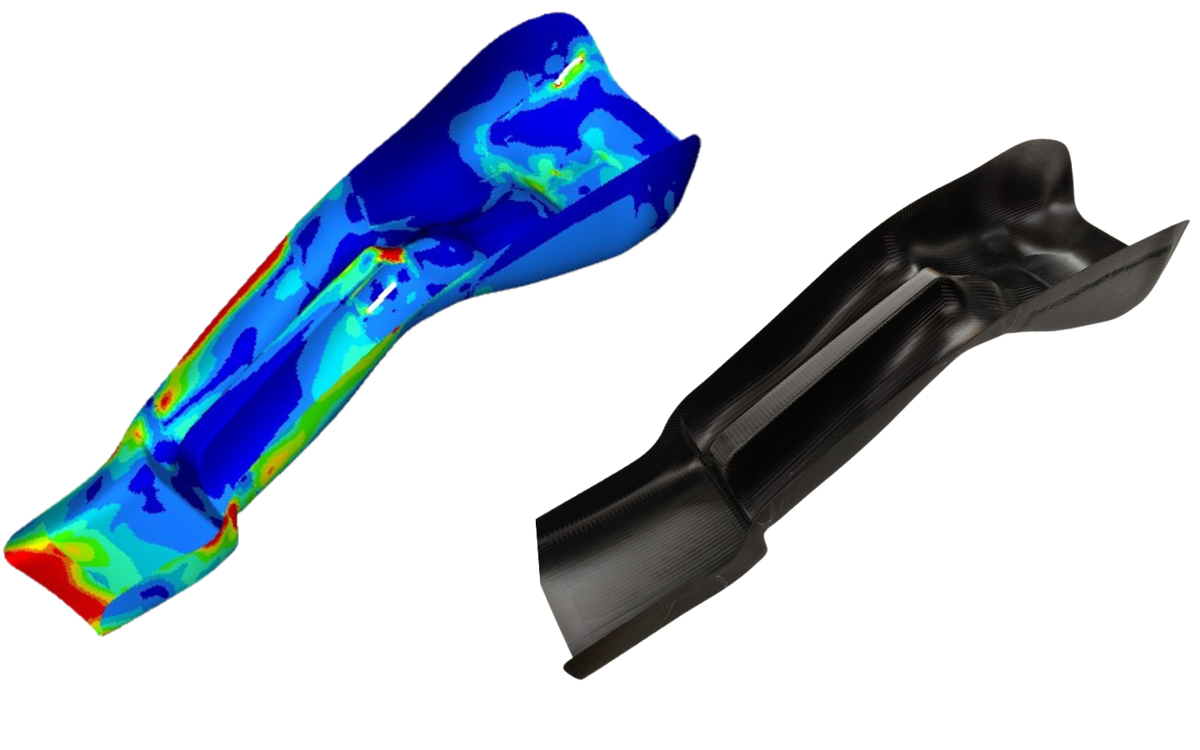

Working with sensor technology from Techni Measure, NCC’s early careers team conducted tests with Emma paddling on top of pressure sensing mats to measure the loads Emma generated while paddling. A finite element model (FEM) – a detailed computer simulation – was used to calculate the precise location and distribution of stresses anticipated during the VL2 class event.

Emma’s existing bespoke seat was laser scanned to generate a 3D model, then painstakingly reverse engineered. FEM analysis informed the design of the laminate to increase the new seat’s stiffness by adding material where strategically required. Supplied by SME SHD Composites, the high-performance material is a unique bio-content epoxy prepreg with lower cure temperatures. These properties helped NCC's team reduce manufacturing waste, costs as well as tooling lead times for a punctual delivery.

Results

The new seat is three times stiffer than its predecessor, allowing for a more efficient power transfer from Emma’s paddle strokes to the boat. By eliminating material where not needed, the overall mass is reduced. Combined, the new seat is already helping Emma move faster over 200 metres.

Next steps

With sensor and data acquisition support from MTC, NCC integrated strain sensors that could monitor the structural health of Emma’s ultimate racing seat on water. Over time, this data could inform any fluctuations triggered by an event or environment, which helps engineers refine the custom seat to support sustainable peak performance for Games to come.

Impact

Whilst this work focusses on a sports application, the capability behind it will feed powerfully into other sectors. For example, continuously tracking the health of parts will provide data to enable a digital twin – a live digital coupling of the state of a physical asset or process to a virtual representation with a functional output. The latter helps engineers study the impact of variables during the design, manufacture, or service life of a product.

Digital twin technology can reduce development time and the need for physical prototypes. It can also improve product quality and performance, cutting waste and lowering costs while enabling predictive maintenance. This enhanced capability directly supports NCC’s ongoing energy transformation work to deliver impact for the UK, be it smarter and more sustainable through-life wind turbines or hydrogen storage solutions.

Emma Wiggs MBE, Paralympic Champion said:

"Working with the brilliant team at NCC has been so exciting. I’m hugely grateful for their expertise and innovation to develop and improve my adaption. Having the best brains working on making the boat go faster is a huge advantage and I'm excited to see what we can do together".

Ben Andrews, Product Technology Manager for SHD Composite Materials Ltd said:

“SHD are proud to support Emma Wiggs in this project. A tailored, optimized composite solution has been delivered by NCC to enable optimal power transfer from athlete to boat. The project also showcased SHD's more sustainable resin system, VTB301. This lower-impact, partially bio-based resin offers a reduced environmental footprint while maintaining the high-performance levels expected of an advanced composite solution. We wish Emma every success in the upcoming Paralympics in Paris."

Matt Scott, Chief Engineer for Technology, NCC says:

"NCC is extremely honoured to collaborate with the inspirational Emma Wiggs MBE once again. With access to a ParalympicsGB great and industry leading experts, our early careers team have gained invaluable on-the-job learning through this project, and produced powerful impact.

"This experience not only fosters growth in their respective areas of engineering interests, but underscores the effect that forward-thinking technology leadership has on realising the UK’s aspirations - from winning gold medals to advancing our net zero ambitions."

Update: September 2024

The final seat is lighter, five times stiffer, and enhances power transfer from Emma’s paddle strokes to the boat, boosting speed over 200 meters – enabling the sub-minute Paris 2024 gold medal win of 58.88 seconds and beating Emma's nearest rival by over a second and a half in the Women's Va'a Single 200m (VL2) title.

Emma, who also won silver at Paris in the Women's KL2 200m. She was powered by a customised paddle designed and manufactured by NCC in collaboration with the Manufacturing Technology Centre (MTC).