NCC and Nexam Chemical provide solution for using composites in extreme temperatures

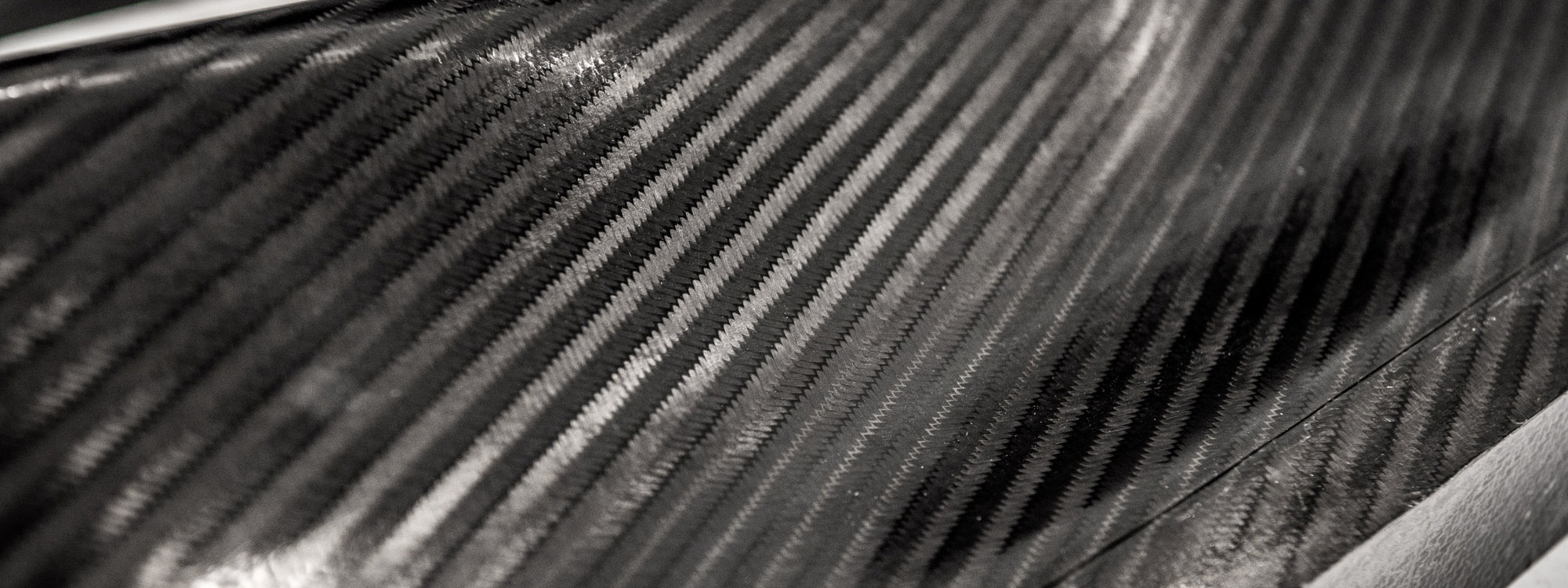

The National Composites Centre (NCC), in collaboration with Nexam Chemical, has successfully manufactured a composite using a high temperature resin, providing a solution to the challenge of using advanced materials in components that need to withstand extreme temperatures.

The NCC’s interdisciplinary expertise in the fields of High Volume Manufacturing, Tooling, Design, Materials Science and Flow Simulation solved the manufacturing challenges existing at elevated temperatures and proved a composite part can be made using resin. This development paves the way for industry to take advantage of the unique qualities composites offer in elements that get very hot, such as sections of engines and the housing for electric batteries, which wasn’t previously possible.

Throughout their research, the specialist team used Nexam Chemical’s new resin system, NEXIMID®. Produced in the UK, NEXIMID® can operate at temperatures up to 400°C, higher than almost all other resin systems. Whilst resin transfer moulding is usually conducted at around 120°C, by developing high temperature specialist equipment – including unique tooling design and high temperature sealings – the NCC were able to keep the resin above 250°C throughout the injection process, allowing the resin’s high temperature capability to be combined with a high processing temperature for a final product that can cope with much higher temperatures than previous composites.

Throughout the process, the NCC, part of the High Value Manufacturing Catapult, has also shown that the resin system is safe, not emitting the high levels of toxic gases that other Polyimide resins can.

“Being able manufacture carbon fibre composites using a UK-produced high temperature resin system is a huge step forward in enabling industry to adopt advanced materials in components that were previously unable to take advantage of them,” said Dr David King, Advanced Research Engineer at the NCC. “The excellent thermal capability of the material expands the boundaries of composites into more demanding applications. Based on the emerging details of this expanded capability we are already working with industry customers on new applications for composite parts, and are excited to further develop our High Temperature Resin Transfer Moulding capability by collaborating closely with Nexam and other partners.”

Boyd Cushing, Business Development for Nexam Chemical UK & Ireland, added: “We are delighted that our five years of collaboration with the NCC has resulted in a major innovation breakthrough for high temperature RTM composites. We look forward to welcoming industrial partners who may have interest with our Scottish origin NEXIMID® non ITAR restricted resin in aerospace and defence applications that are looking for high performance material composite parts.”

Following this successful collaboration, Nexam Chemical have joined the NCC as an SME Affiliate Member, paving the way for further projects that will aid industry in using high temperature resin transfer moulding to their advantage.