January Newsletter

News from the cluster

Welcome to the latest edition of our Space West Newsletter. We're dedicated to delivering space-related news, updates, and knowledge. With each newsletter, we aim to keep you informed about the most recent discoveries, advancements, and stories from the world of Space in the South West.

About Space West

Space West is a regional consortium of academic and industry partners designed to accelerate growth and innovation in the space sector within the region and nationally. The Space West programme hosted by the National Composites Centre, in partnership with West of England Combined Authority, the Centre for Modelling and Simulation, the University of Bath, the University of Bristol and the University of the West of England.

Exploring new horizons: The rapid growth of the South West Space Sector explored in The Engineer's interview with Rebecca Huffee

Exciting insights into our region’s space sector were shared in the latest edition of The Engineer UK with an interview featuring Rebecca Huffee, Space West Cluster Manager.

The UK space industry is growing three times faster than the global average. The spotlight on the South West space sector underscores its pivotal role, emphasising the region's substantial contribution, particularly in academic research.

Jonny Williamson's deep dive into the present and future of South West aerospace here.

South West Research and Industry Call for Participants

Exeter Science Centre have been announced as one of 22 science centres across the UK to join the ‘Our World from Space’ programme. The 2-year programme created and developed by the Association for Science and Discovery Centres (ASDC) will be exploring the relevance of UK space sciences for the future health and sustainability of our planet. They have a call-out for researchers and industry professionals to support this work across the South West find out more here.

South West Regional Defence and Security Cluster Event - Funding and Opportunities with NATO & DASA DTEP

Space West attended this fantastic event last week, hosted by the National Composite Centre focused on funding and opportunities for driving innovation in the defence and security sectors.

Anita Friend, Head of DASA (Defence and Security Accelerator) set out the strategic importance of innovation to UK security and progress on developing new ways of working and support that can overcome barriers to innovation in the sector. Cynthia Shaw, NATO DIANA (Defence Innovation Accelerator for the North Atlantic) Delivery Team provided updates on the DIANA programme and Mike Madden briefed on the DASA DTEP programme.

Of particular interest was information about the newly established NATO Industry Advisory Group (NIAG) SPACENET platform that will help to establish links between space companies and NATO. NIAG-SPACENET is open to all Space industries from across the NATO alliance. For questions and further guidance, including details for national points of contact, industries may contact the International Staff at: [email protected]

Spotlight on Techmodal

Techmodal is a Data Analytics consultancy based in Bristol, delivering data-driven insights to clients across Defence and Critical National Infrastructure for the last 17 years. We combine expertise in data science, modelling, and analytics technologies with deep customer domain knowledge to enable our clients to access valuable insights from their data quickly and effectively.

Our approach is user focused and Agile, prioritising delivering value early in engagements. We work with customer technology wherever possible to maximise speed of outcome, align with wider digital and data strategies and ensure maximum re-use and value from customer investments.

Our offerings provide the following to insights to our customers:

- Applied Data Science: Applying data science tools and techniques to real-life operational challenges has enabled Techmodal to support our customers get quicker more effective insight into their toughest challenges. Examples including development of satellite image analytics, acoustic data analytics, optimisation of complex systems, forecasting and prognostics.

- Data Modelling: Applying simulation and modelling techniques to explore how our customers’ complex organisations respond under different conditions or assumptions. Providing customers with valuable insights, supporting business, operational and strategic decisions and enabling optimisation. Examples range from optimising aircraft training schedules to balancing cost and maintainability of a fleet of ships.

- Operational Insight: Providing customer side data-led insights into operational challenges. Our embedded domain experts work alongside our customers to provide data modelling and analytics coupled with deep Support and Logistics knowledge to inform customers operational, strategic and policy decisions. Examples include data-led wargaming, informing tactical decision making and helping set policy and doctrine.

Research in Focus

The Space West Region hosts three world class universities, as well as multiple Research Technology Organisations. Through these newsletters we will share highlights of the remarkable research taking place in these prestigious institutions. All three universities hold Impact Acceleration Accounts which are designed to help universities translate research to real-world impact. If you are interested in collaborating with a university, Space West can connect you to the right support.

CFMS is a digital engineering Research Technology Organisation (RTO), based at the Bristol and Bath Science Park. We specialise in combining secure, onsite high performance compute facilities with expertise in computing, simulation, robotics and machine learning to push the boundaries of modern engineering.

Mark Woods, CSO and Head of Robotics, Autonomy and AI Group

CFMS are involved in several research projects across a range of sectors including aerospace, space, transport, nuclear & energy, and construction. A particular current research focus is in developing tightly coupled multi-physics simulations of complex engineering processes. These couple several physical domains such as heat, mechanics and fluid flows, into single solvers rather than the traditional approach of alternatively stepping separate simulations and passing information between them at each time step. Using residual based methods, rather than direct numerical inversion techniques, enables solves to be scaled to large compute machines and simplifies the coupling of different variables in the problem.

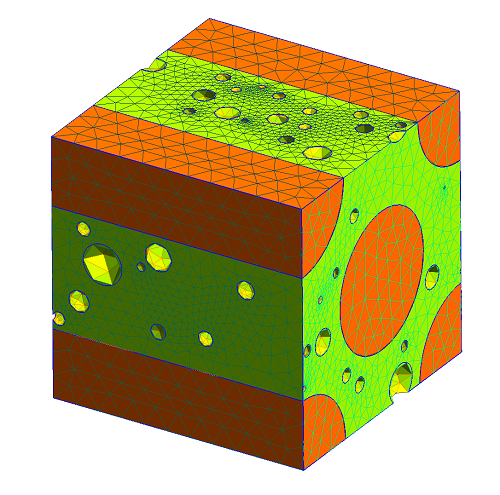

Micro scale simulation of porosity damage in composite manufacture

This yields improvements in accuracy and execution time, enabling engineers to tackle increasingly complex problems. CFMS are applying this approach across a number of fields, including coupled multiscale modelling of composite manufacture and structural performance, and simulations of metallic additive manufacturing processes. These models are deployed on compute facilities far beyond what is available on traditional desktops which allows both larger, more complex models to be executed as well as being able to run more models. Using this, CFMS are driving a fundamental change in the approach to undertaking modelling campaigns and digital engineering, heavily utilising automation with intelligent design of experiments, optimisation and sensitivity analysis to efficiently execute a deeper exploration of design spaces. This often yields novel designs from regions of the design space an engineer has not considered due to their preconceptions of what the answer should be. As well as yielding better designs, it is giving designers more robust solutions as they can quantify the variation in performance when the design hits real world variability. This is reducing the time and cost of development, reducing the number of physical prototypes that need to be manufactured and tested. Finally, as a commercially secure facility, we are able conduct this research using real-world, proprietary industry data which significantly improves confidence in the simulation results and enables faster technology readiness level (TRL) transition.

Opportunities

Run by the Defence and Security Accelerator (DASA) aims to inspire companies to win new business, develop industrial capabilities, and provide new cutting-edge answers to defence problems at home and abroad, ensuring the UK expands its competitive, pioneering and world-class defence and security industries. The £16 million programme is designed to support small and medium-sized enterprises (SMEs) across the UK to develop innovative materials, technologies and processes, and to enhance defence supply chains.

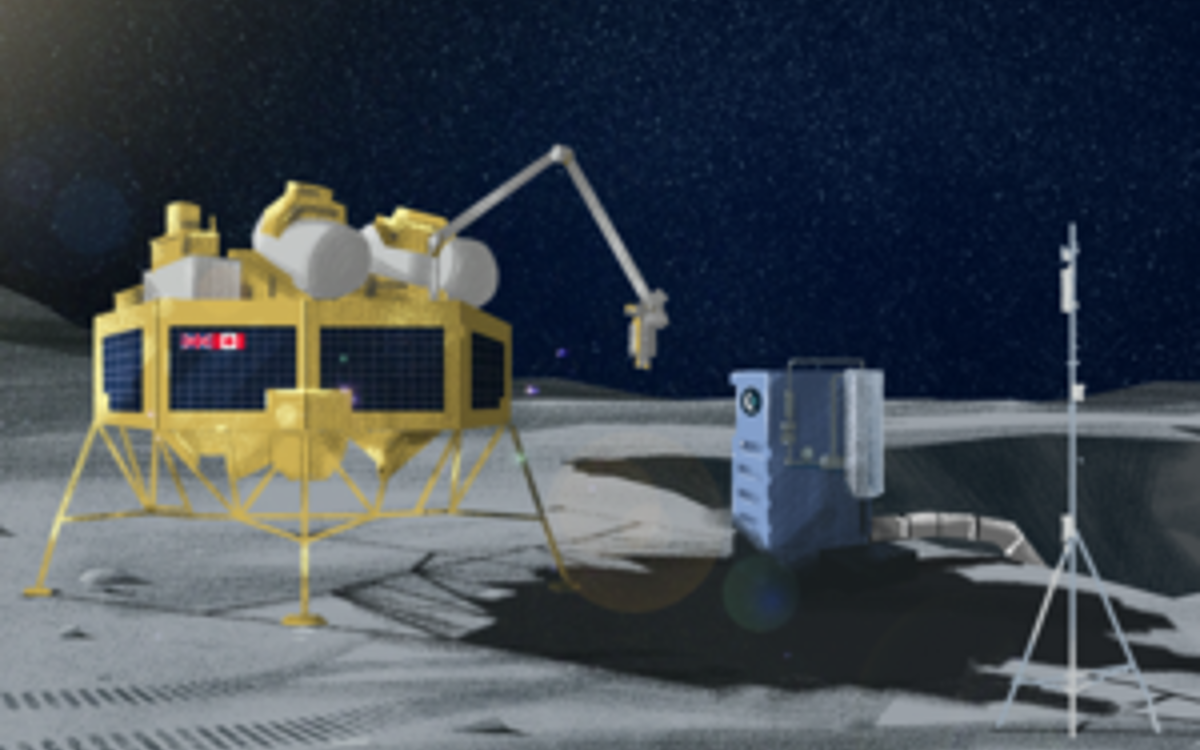

The joint UK-Canada £1.2 million Aqualunar Challenge is launching to support development of water-purifying technologies for the Moon.

ESA is seeking promising business ideas for new service concepts that empowered by Moonlight’s lunar communication and navigation services and address the needs of final customers in the lunar environment or down on earth, as well as related short term business opportunities.

West of England Combined Authority are supporting businesses in the region to explore the benefits from the implementation of digital technologies. Providing access to grant funding, bespoke expertise and guidance for your business as well as skills and training.

The UK Space Agency is helping connect Investors with Innovators and is running two investment events, in Edinburgh and Leeds. Applications for the Leeds Investors pitch event close on the 19th of February so if still time to apply.

Applications are open for internship projects and close on the 2nd The Programme funds space related organisations to host university students to deliver a specific project. SPINterns are employed for a minimum of 8 weeks (if longer the additional cost must come from the employer's budgets). They work on a defined project which will support their personal development and particularly encourage the development of skills which the sector has identified in short supply.

Events

1st February Foot Anstey Offices, Bristol. Join this workshop delivered in partnership with Space West and Deloitte, to hear more about challenges faced by the Offshore wind sector and the Climate & Resilience sectors that space technologies could solve. Challenge setters come with problem books from South West Water, Environment Agency, Celtic Sea Power and Crown Estates.

Rebecca Huffee, Space West Cluster Lead will be at Space-Comm. The Space-Comm Expo gathers space, aerospace, defence, downstream and upstream industries for two days of high-level networking, discussions, education and business, focused on the commercial future of space.

Supported by key industry associations and influential bodies, Space-Comm Expo showcases the end-to-end supply chain for products, services and applications supplying and informing commercial enterprises, Government and defence organisations, and developments in technology.

16th February, UWE, Bristol - This full day workshop, delivered by Space West in partnership with UKSA and ESA, provides your business with all that you need to know to be working with ESA. ESA’s Gertrud Talvik will be joined by speakers from CGI and Thales Alenia Space and iCOMAT as they build on Gertrud’s session to provide an industrial perspective of working with ESA.

UKSEDS National Student Space Conference Bristol March 2-3rd March 2024 National Student Space Conference 2023-UKSEDS - UK Students for the Exploration and Development of Space

Stay connected with the latest updates from Space West!

Subscribe to our newsletter now and receive exciting news and space-related insights directly in your inbox. Join our space community by emailing us at: [email protected]

Space West 2024 Activity Page

Stay connected and witness our exciting endeavors throughout the year. Explore upcoming events, collaborative initiatives, and engaging projects.