Braiding & Winding

Braiding & Winding

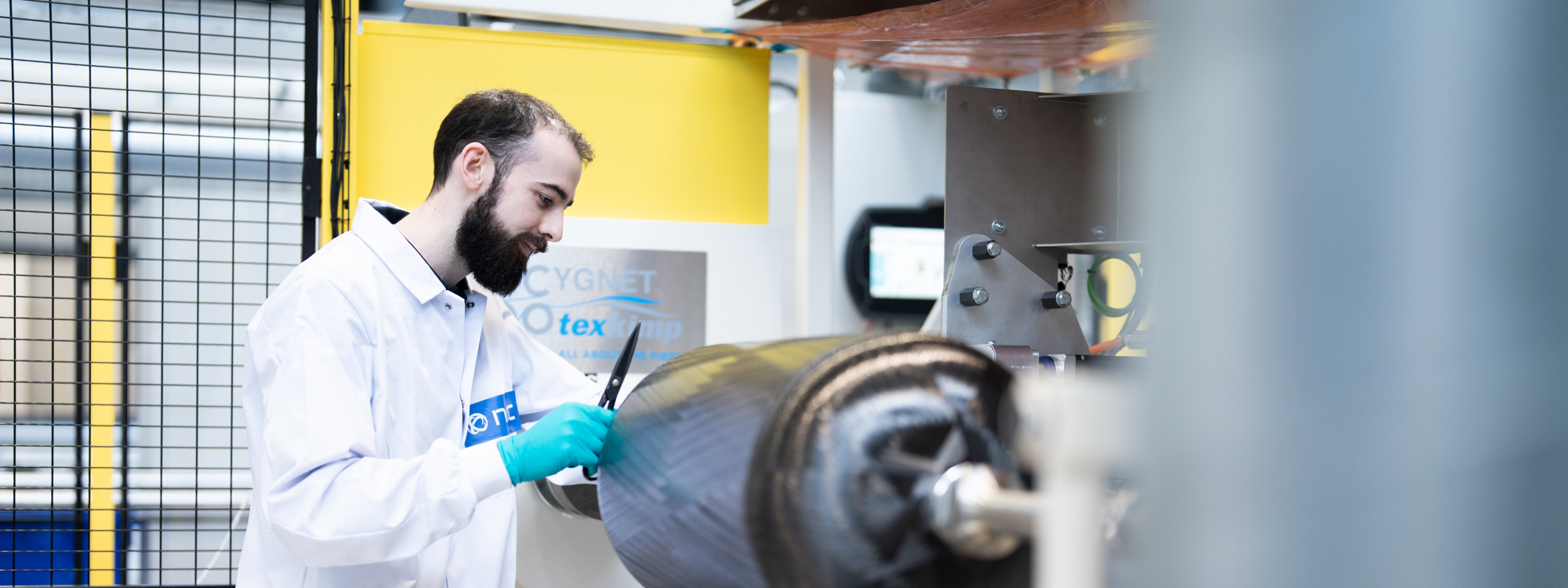

NCC has the only two ring braider in the UK. Comprising 288 and 192 spools, our braider is more than twice as flexible as a single ring braider. The two rings and a 10m long gantry enables us to braid complex circular, rectangular and convex sections, in the widest possible range from 50mm to 800mm equivalent diameter. NCC's braider is also capable of a very high deposition rate - up to 50 kg/h.

Filament Winder

NCC introduced a filament winder with the ability to wind towpreg or wet winding of dry fibres. This high deposition rate machine has the ability of winding fibre around a pressurised liner using a 4-axis winding system.