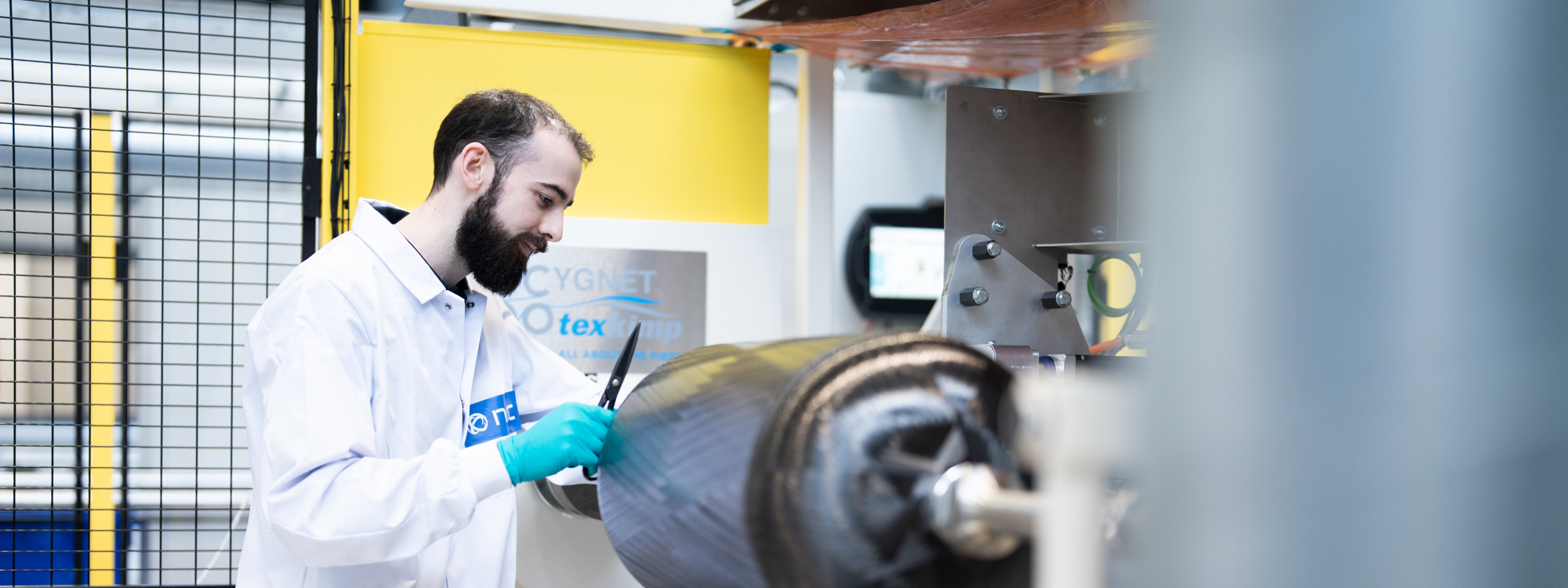

Pressing & Overmoulding

Overmoulding

A continuous fibre composite sheet is melted and formed. A thermoplastic polymer is then injected over the surface in this fully automated process, achieving production cycle time of 1 to 5 minutes. The process combines the structural benefit of long-fibre reinforced composite sheet with the speed and geometric complexity of injection moulding. Applications include;Thermoplastic continuous fibre sheet – with overmoulded stiffening ribs, bosses or inserts, and aerospace and rail interiors, automotive structural members, battery and motor casings.