Developing new and improved moulding and forming capabilities across pre-preg, dry-fibre and thermoplastic formats

Resin infusion

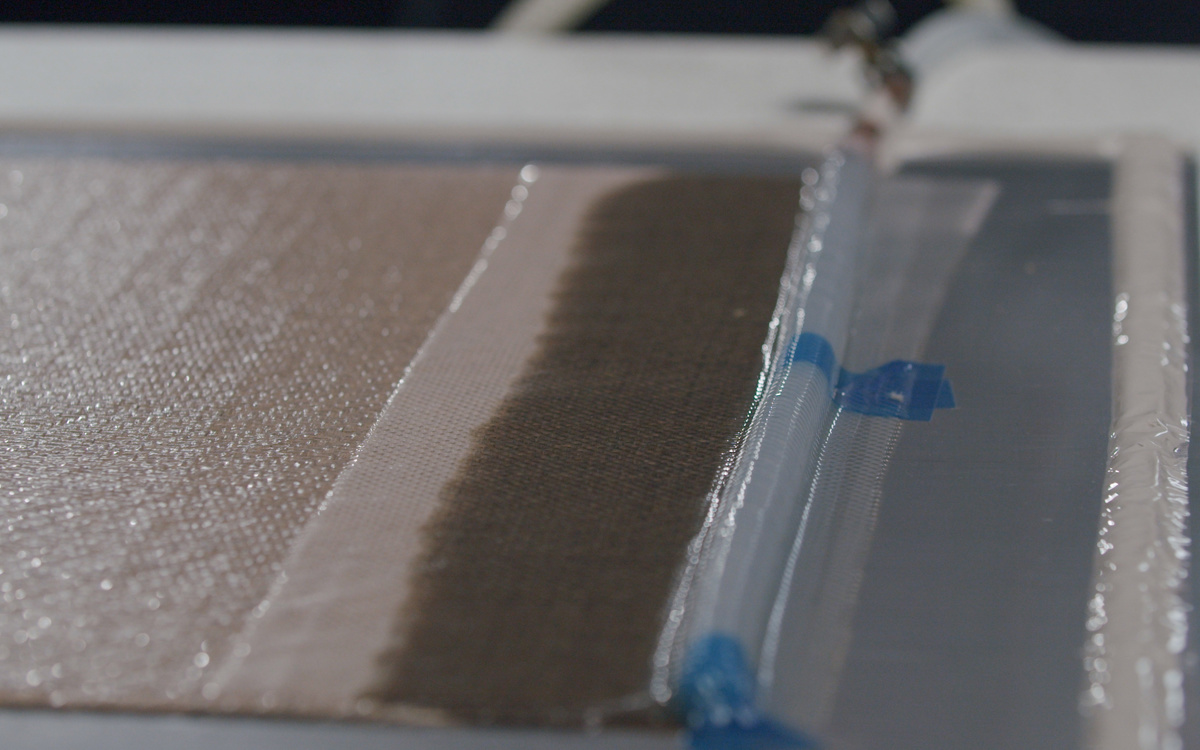

Resin infusion is a potentially much lower cost manufacturing method than the current prepreg and autoclave solution. With 11 resin infusion machines, applications range from large, high-performance structures such as aeroplane wings and wind turbine blades to bridge decks. The highest-pressure machine can inject up to 200 bar and highest temperature machine can operate 300C resins.

Moulding composites using high temperature resins and functional additives means that finished components have greater mechanical performance in harsh environments. The technology stirs, de-gasses, heats and injects a wide variety of 'difficult to process' resin systems into a variable geometry Resin Transfer Moulding (RTM) tool with instrumentation of all key process parameters.