We connect technology strategy to real-world delivery through our end-to-end engineering services

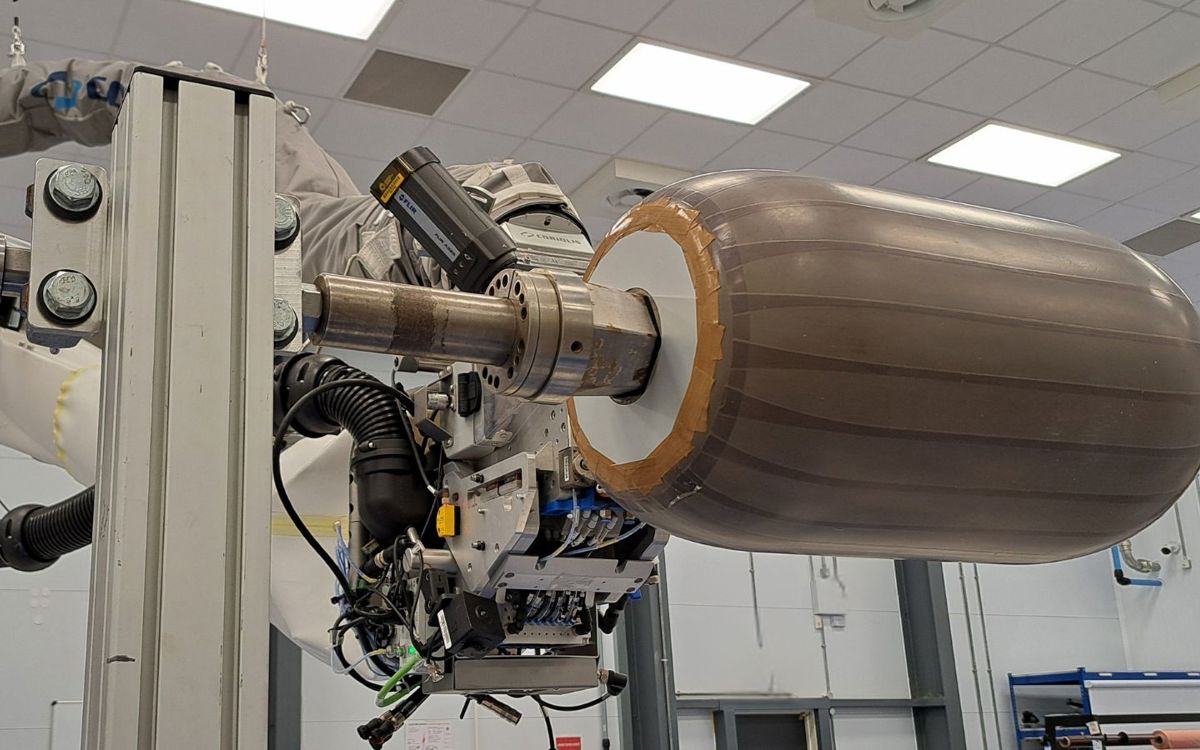

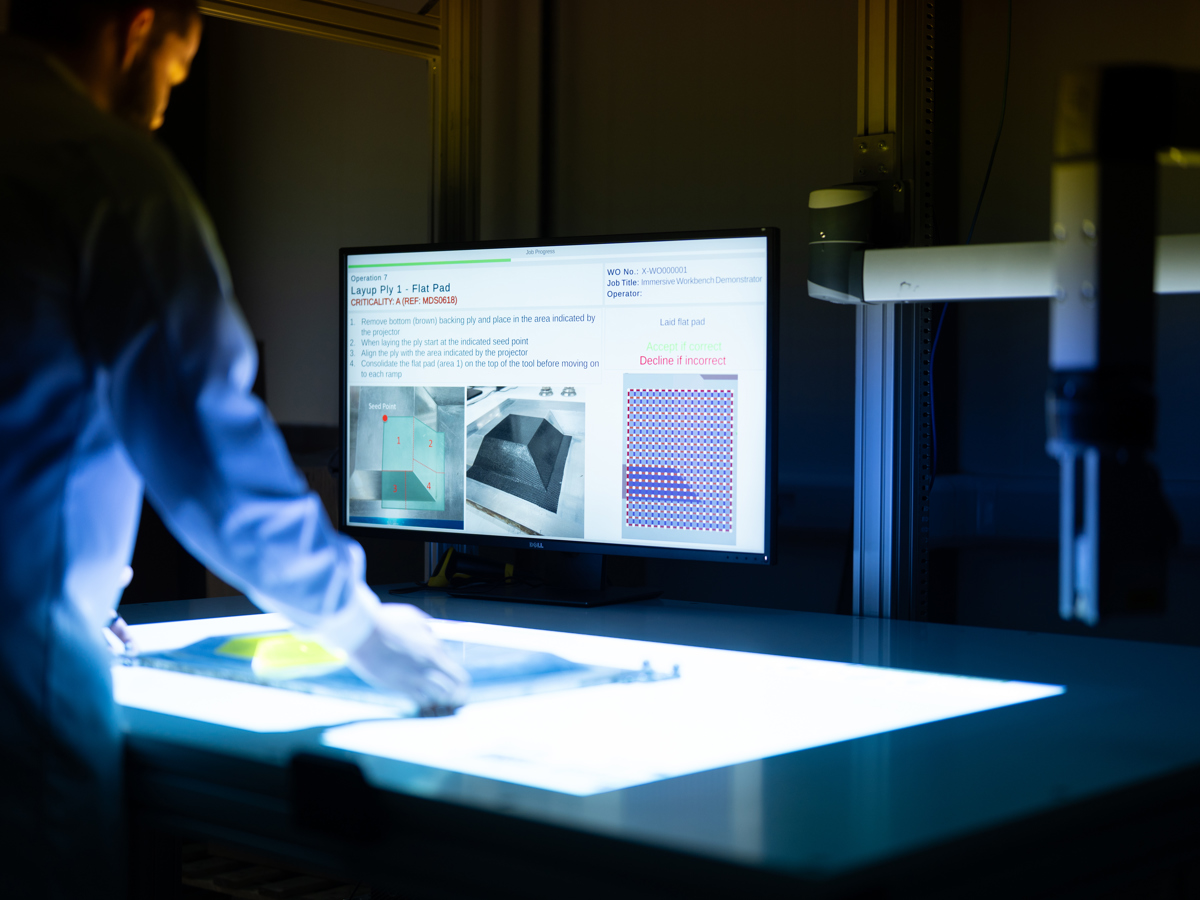

An extension of our customers’ capabilities, we demonstrate and de-risk new product development and manufacturing to validate technologies at rate and scale.

We pull through a broad portfolio of science and engineering research to enhance existing products and processes – improving productivity, enabling supply chain growth or extending service life through innovative repair or life-extension technologies.

We unlock end-stage value through recycling, repurposing or low environmental impact disposal of critical materials.

We innovate through technology clusters – discrete elements of material, product or process development or integrated into system-level challenges:

Get in Touch

Connect with our Specialists at NCC to find out more about our world-leading innovation capabilities and how we can support your business.

We innovate through technology clusters – discrete elements of material, product or process development or integrated into system-level challenges

We connect technology strategy to real-world delivery through our end-to-end engineering services