Newsletter Issue 8

Welcome to the latest edition of our newsletter

As we come to the end of 2023, this last newsletter of the year serves as a capsule edition, encapsulating our remarkable trajectory throughout 2023. It showcases our news, thought-provoking case studies, while also outlining the exciting professional training and workforce transformation opportunities on offer.

Navigating Innovations - 2023 in review and the path ahead to 2024

2023 has been marked by monumental strides forward. Already a centre of excellence for digital engineering, we’re set to welcome the UK’s most powerful supercomputer, Isambard AI. Hosting this unprecedented £225 million investment provides a springboard for the NCC to accelerate our journey from digital innovation to impact.

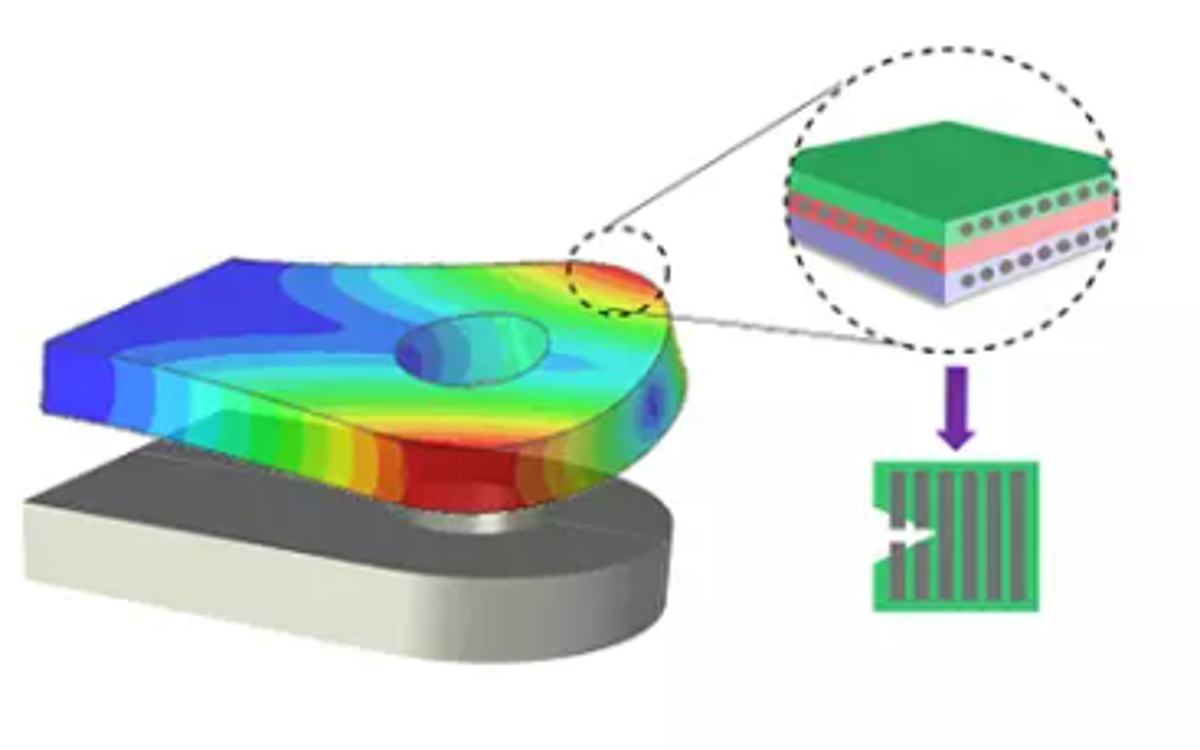

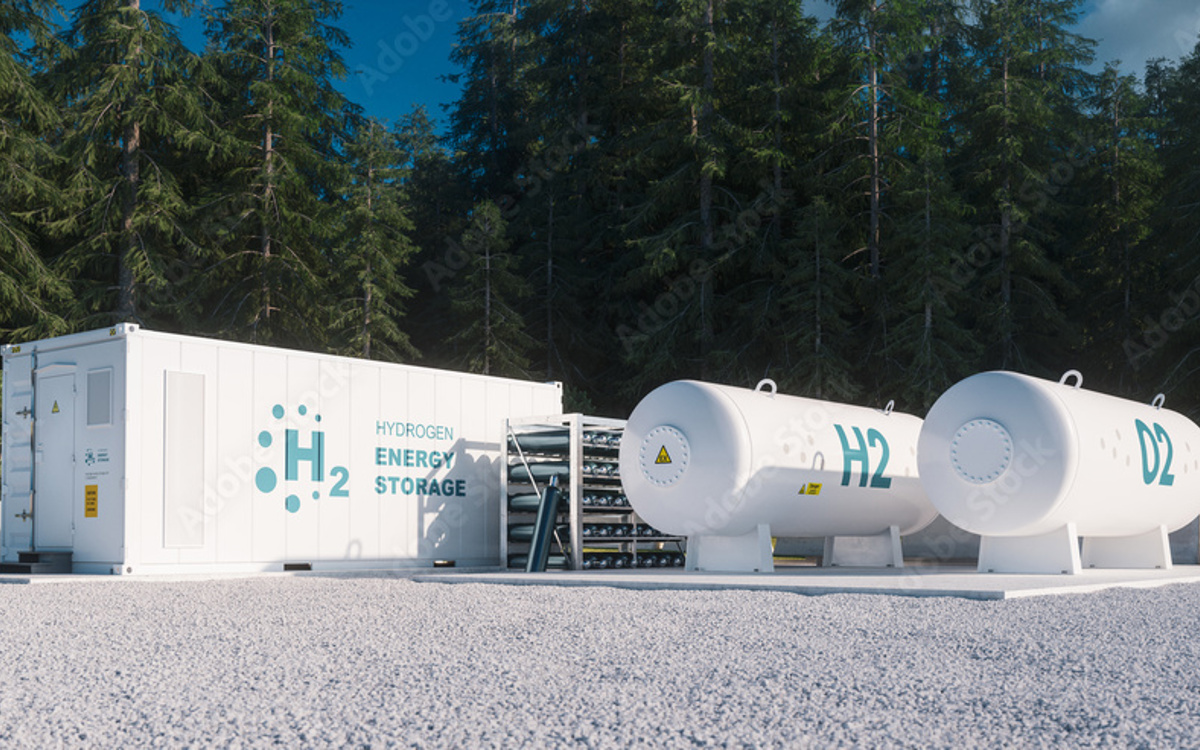

Our Core Programme 2023 diligently advanced key technologies, facilitating industries to embrace advanced materials as part of their pursuit toward achieving net-zero practices. Most notable has been our strides in hydrogen technology. Our recent hydrogen pressure vessel static burst test achieved a staggering 1,776 bar, surpassing certification targets and validating our simulation capabilities.

Additionally, under our initiatives in the Hydrogen Skills Alliance and Hydrogen Skills Framework have further solidified our position as industry frontrunners in this domain. We are committed to supporting the building of a skilled workforce necessary to support the growth and development of the UK hydrogen sector and deliver net zero ambitions.

2024 promises another exciting chapter for the NCC, as we gear up for another impactful year of innovation, breakthroughs, and transformative endeavours.

As the festive season approaches, we’d like to extend our warmest wishes to all. In line with our annual tradition, the NCC team is fundraising for two noteworthy local causes: the Bristol Children’s Charity and the Julian Trust Nightshelter. We invite you to learn more about the remarkable work undertaken by these two impactful charities.

Wishing you a wonderful Christmas and a prosperous New Year.

Latest News

From supercomputers to technology collaborations we have a wealth of information to share.

The NCC's efforts towards materials development for hydrogen storage has been featured in the Institute of Physics (IOP)’s ‘Physics Powering the Green Economy’ report. Learn how our cross-sector capability aims to meet the UK’s net zero ambitions while securing future commercial competitiveness.

NCC apprentice Thomas Warr recently participated in the BBC Bitesize School Tour in Bristol, contributing to an engaging event aimed at promoting opportunities in Science, Technology, Engineering, and Mathematics.

SusWIND has completed a successful second year of its industry programme, focused on creating a viable circular economy for wind turbine blades. The 2023 SusWIND Annual Review presents a year of insights and achievements from the programme.

A new state-of-the-art centre, supporting the development and commercialisation of advanced sustainable materials, will bring high-impact investment to Rochdale and the Greater Manchester city region. The two-year Centre of Expertise in Advanced Materials and Sustainability (CEAMS) supports the development of advanced sustainable materials, and is led by a consortium of expert partners, including the NCC.

Details of a £225m investment from the Government to create the UK’s fastest supercomputer to be hosted at the National Composites Centre have been announced. The funding injection, part of a £300m package to create a new national Artificial Intelligence Research Resource (AIRR) for the country will make the UK a world leader in AI.

The NCC's Core Programme 2023 will continue advancing key technologies and capabilities to enable industry to take advantage of advanced materials as they strive for net zero practices.

Welcome to the November edition of our Space West Newsletter where we'll bring you the latest discoveries, innovations, and stories from the world of space in the South West.

Space West is a regional consortium of academic and industry partners designed to accelerate growth and innovation in the space sector within the region and nationally. The Space West programme hosted by the National Composites Centre, in partnership with West of England Combined Authority, the Centre for Modelling and Simulation, the University of Bath, the University of Bristol and the University of the West of England.

A new £4.7m 18-month phase of Joule Challenge, a UK Government-funded collaborative programme has been announced. Collaboratively delivered by the National Composites Centre and the Offshore Renewable Energy (ORE) Catapult, it is funded by the Department for Energy Security and Net Zero’s £1 billion Net Zero Innovation Portfolio (NZIP).

The National Composites Centre has announced that it has successfully tested a range of composite cryogenic storage tanks with liquid hydrogen that it has designed and manufactured, considered one of the first tests of its type carried out in the UK.

The project ‘GW-SHIFT: Great Western Supercluster of Hydrogen Impact for Future Technologies’ led by the University of Bath and University of Exeter has secured £2.5 million from the Engineering and Physical Sciences Research Council (EPSRC) as part of their Place Based Impact Acceleration Account awards (PBIAA).

The National Composites Centre is delighted to announce that bp will be joining the SusWIND programme.

The NCC is delivering a new pilot from HVM Catapult to support UK SMEs with their energy costs. The Manufacturing Energy Toolkit aims to help small businesses make their processes more energy efficient, cutting their energy costs and greenhouse gas emissions while improving profitability.

Budding cyclists from the Bristol-based National Composites Centre have raised £10,000 for charity after embarking on a gruelling 900km bike ride from Bristol to Cologne – crossing five countries in just five days.

Leonardo UK has signed a Memorandum of Understanding (MoU) with the High Value Manufacturing (HVM) Catapult, a network of seven world-class research and innovation centres that turn great ideas into commercial realities.

The University of Bristol has been chosen to host a new national supercomputer research facility at the National Composites Centre, focused on artificial intelligence (AI), the government announced today. The new AI Research Resource (AIRR) will serve as a national resource for researchers and industry experts spearheading AI innovation and scientific discovery – and places Bristol at the centre of the AI revolution.

Technologies that will reshape the defence manufacturing industry and equip armed forces for years to come will be on display at this year’s Defence and Security Equipment International (DSEI) global trade show.

A Technology Innovation Partnership for Net Zero Aviation in the South West has been launched. Focused on delivering transformational innovation to advance net zero flight, the founding partners are the NCC, advanced propulsion R&I centre IAAPS, and the Universities of Bristol and Bath. The partnership will create a significant national capability that combined far exceeds working independently.

Case Studies, Impact and Opinion

Our core research and development strategy plays a key role in innovation, uncovering new opportunities, and fostering competitive advantage to help UK companies to build sustainable products and services. Here, we have shared a small selection of the most recent case studies, innovation impacts and opinion articles from our teams

The CERCOMP UK collaborative research project advances aircraft propulsion technology, while paving the way for a secure supply of affordable advanced ceramic composites in the UK. Find out how this experience builds the HVMC consortium's capability as a lead technology cluster to help develop, expand, and diversify UK’s CMC market offerings in key industrial sectors.

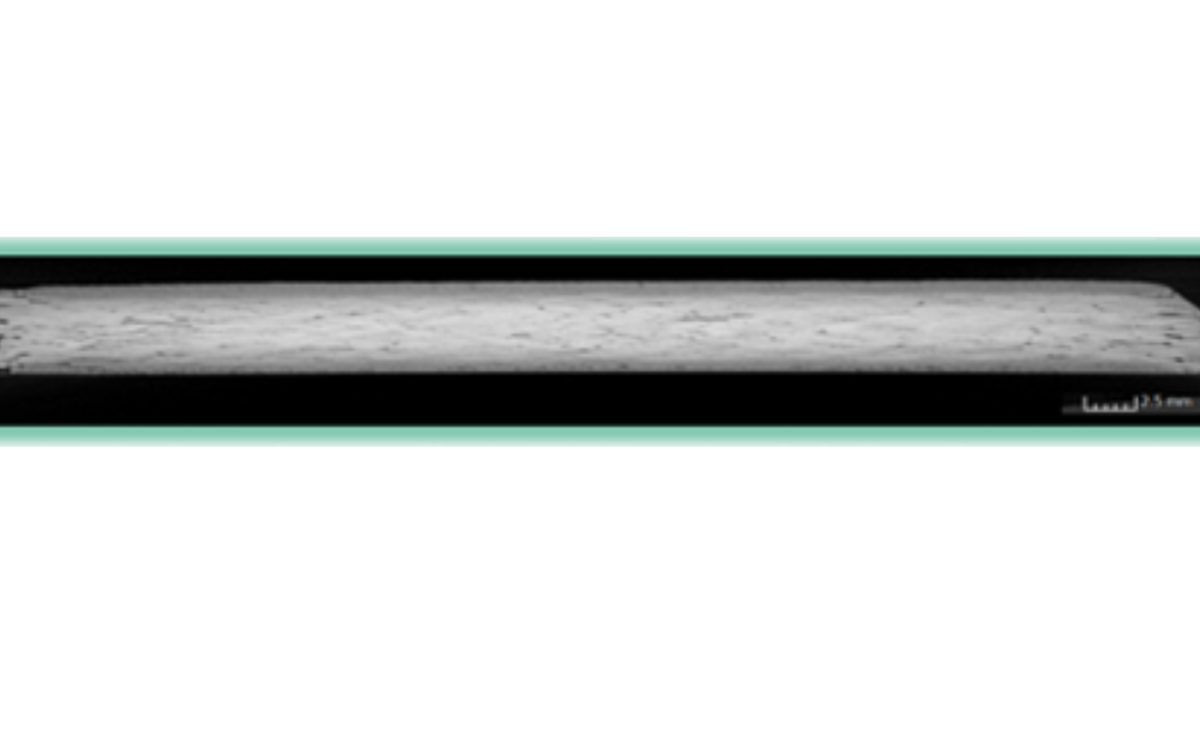

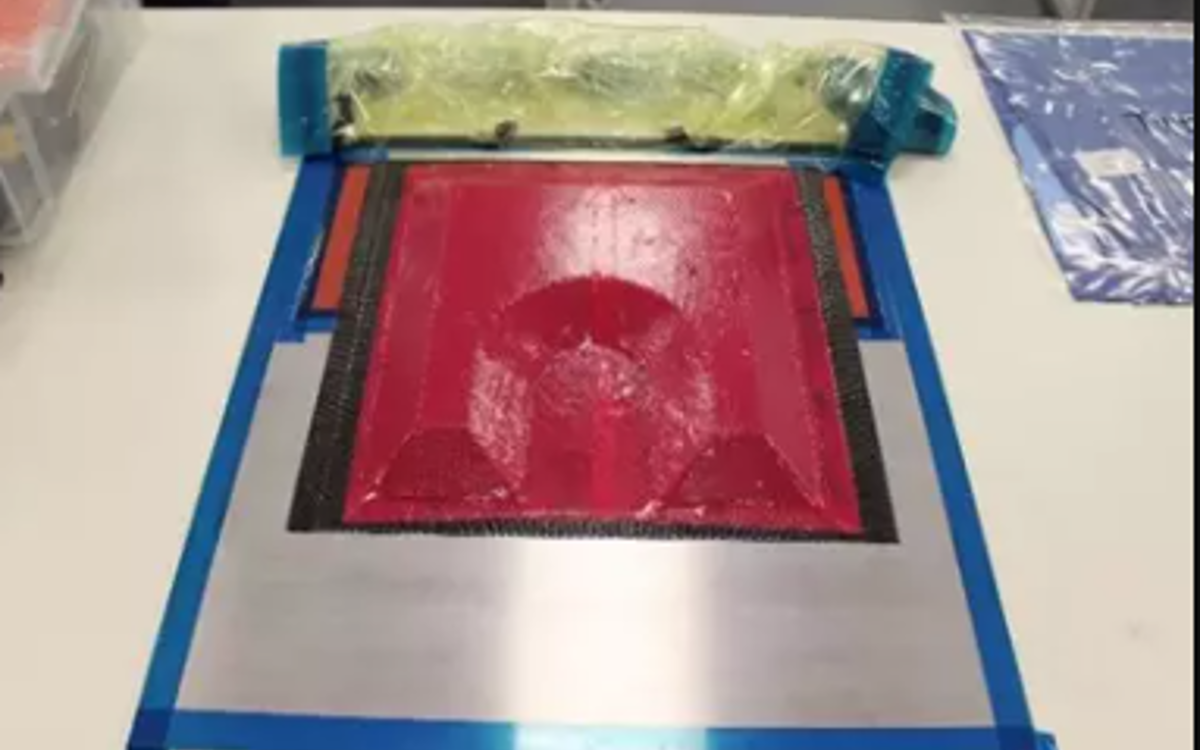

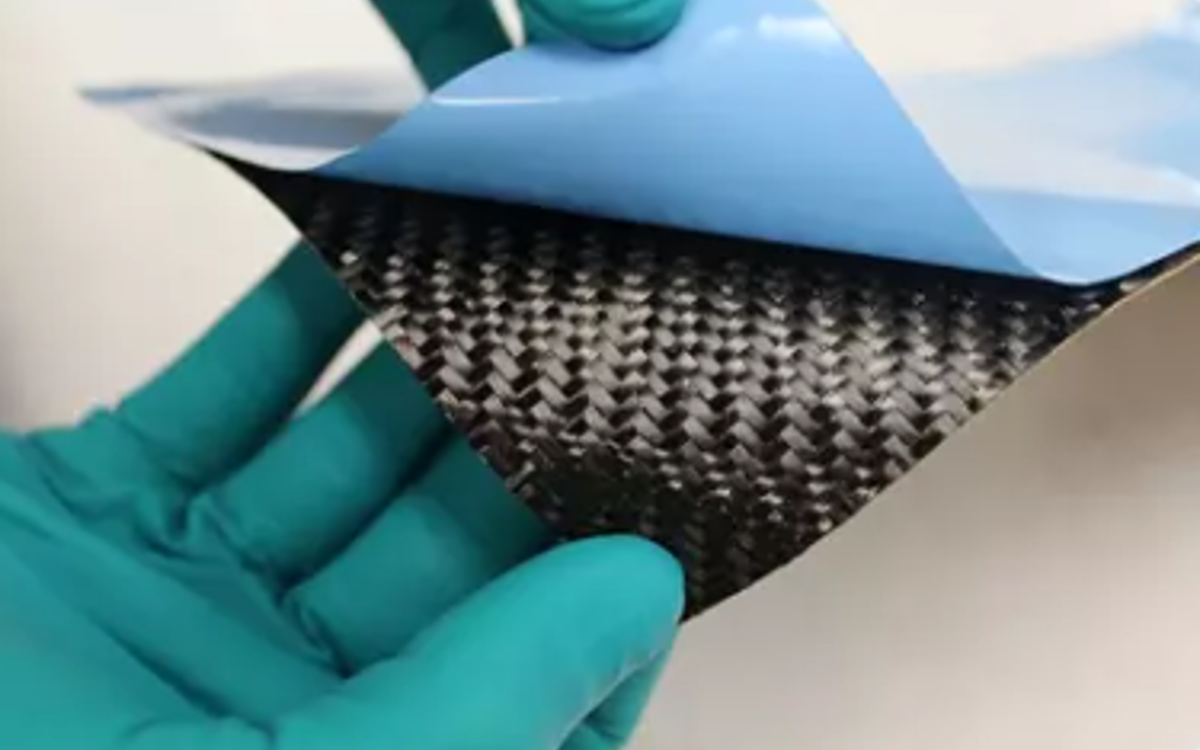

In support of Airbus' Wing of Tomorrow programme, a collaborative team of engineers at the National Composites Centre investigate materials, manufacturing, and component sub-assembly techniques to achieve a world-first full scale 17-metre integrated wing skin infused in one step.

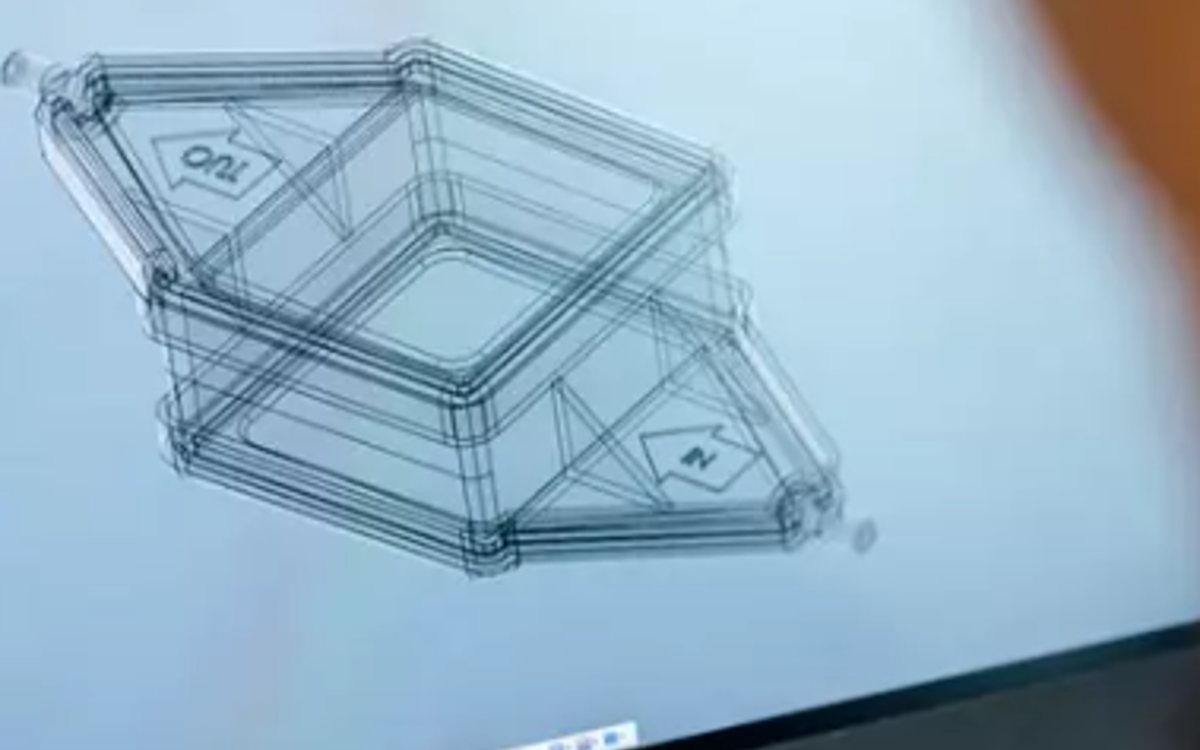

Engineers at the NCC have worked with UK SME, Solar Capture Technology, to develop the initial design for a novel roof tile with integrated solar modules that can be used in domestic and industrial roofing applications to make solar power more efficient and affordable.

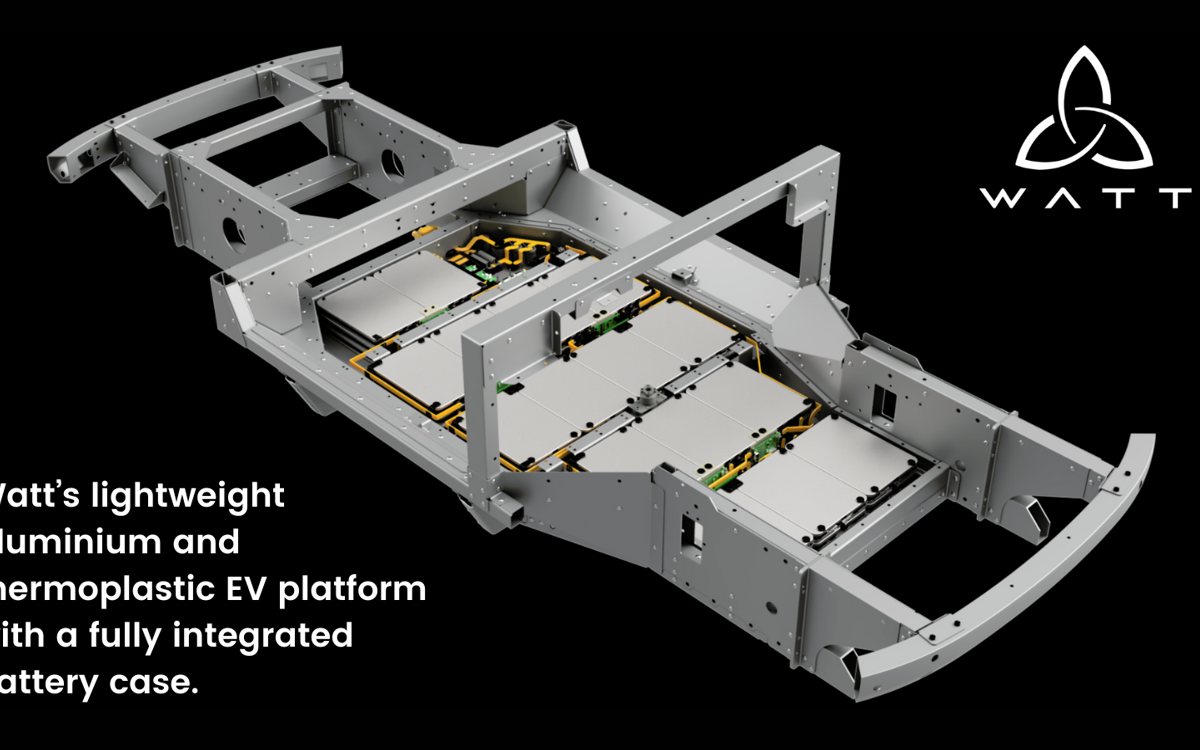

The NCC offers EV specialist Watt Electric Vehicles a faster, lower cost and more sustainable solution to enable timely business expansion to support the local electric vehicle supply chain needs.

Professional Training Opportunities

Elevate your expertise through our diverse training courses. Engage with various subjects and flexible learning methods tailored to meet your needs. Join us in shaping a brighter future at our state-of-the-art facility and take your skills to the next level. In 2024 we are thrilled to be collaborating with South Devon College to deliver a series of 3 training courses all designed to advance expertise in composites. Lasting 1 or 2 days, the courses will be facilitated by expert trainers from the National Composites Centre and delivered at South Devon College.

National Composites Centre (NCC) is teaming up with South Devon College to bring you a series of 3 training courses during a special - Composites Training Week. The courses are all designed to advance expertise in composites, lasting 1 or 2 days and will be facilitated by expert trainers from the National Composites Centre.

The seven centres that make up the High Value Manufacturing Catapult (HVM Catapult) have come together to create 'Hydrogen awareness: make it; move it; use it’, a series of open access online modules for all manufacturing sectors.

This course is highly recommended for individuals and teams who are already producing prepreg parts and want to improve their processes and the quality of their finished products.

This course will give you an understanding of the requirements that are important to consider in the composites world, along with a series of tools and techniques that will enable you to create robust concept designs for every new project you undertake.

During this course we'll give you the background knowledge you need to optimise your use of prepreg materials in order to achieve the best possible outcomes. We'll also teach you the techniques used by technicians and you'll have the opportunity to practice what you've learnt.

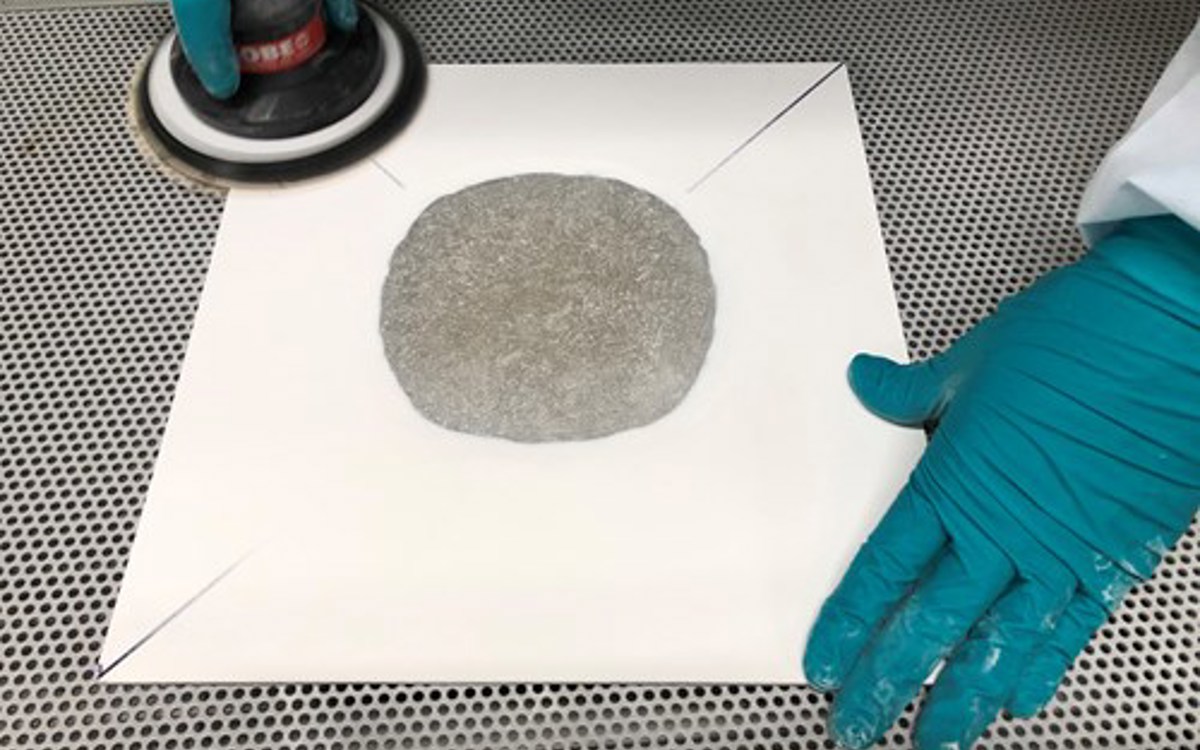

This is a highly practical course, which will teach you cost-effective ways of producing your own moulding from scratch. You'll gain the knowledge you need to produce quality parts and learn how to avoid common errors.

Future legislation will dictate that you can't just discard composite components into landfill and the need to repair, in order to extend life expectancy, is set to increase even further. Repair of composites can be more complex than the repair of more traditional metallic components and, of course, there is always the need to regain structural integrity whilst maintaining functionality.

Use of the correct joints is vital to creating highly functional composite structures. We highly recommend this course for composite designers who want to improve their approach to bonding and joining composite materials ensuring better results.

If you need to focus on improving the strength and stiffness elements of your composite designs this course will give you a knowledge of composite properties and an understanding of how each of the plies effect the global part.

If you're looking to implement automated processes into your existing composite manufacturing activities this course will give you the knowledge you need to explore and assess techniques to take your production to the next level.

If you're a Technician who's new to using resin infusion for composites manufacture, this course will provide you with the skills and knowledge to avoid common mistakes and safely produce better parts.

As an engineer who is currently responsible for measuring and inspecting metalics, and are now moving into the world of composites, this course will give you the tools and knowledge you need to ensure that you understand the different challenges composites present and the techniques they require.

In this foundation level course we'll introduce you to the terminology, the materials, their properties and the production processes used in the composites industry.

This course provides an introduction to how businesses can start thinking differently about their operation, products and production processes in order to meet new legislation and support the drive for change.

Events for your diary

Mark your calendars for upcoming events where you can connect, collaborate, and engage with us. Whether it's in-person or virtual, we can't wait to meet you there.

Join the National Composites Centre at Polymer in Hydrogen and Carbon Capture and Storage.

Join the National Composites Centre at Polymer Engineering for Energy - Enabling Efficiency in the Oil and Gas Sector.

Dr. Peter Giddings, Chief Engineer for Energy at the National Composites Centre, will be participating in a panel session “Creating a sustainable offshore wind supply chain” at the UK Offshore Wind Supply Chain Spotlight Conference.

Our next Technology Day will bring together the UK Defence community to explore the topic of 'Smart Materials for Defence Applications.' We aim to uncover the potential of functionalising composites and the development of hybrid materials to drive significant advancements in operational effectiveness.

The National Composites Centre will be exhibiting and presenting at JEC World 2024, the global trade show for composite materials and their applications. Held in Paris, JEC World is the industry’s leading event, hosting all the major players in a spirit of innovation, business, and networking.

Marc Funnell, Head of Digital Engineering at the National Composites Centre will be presenting on the topic of 'Towards Certification by Analysis – the potential role of Digital Twinning in regulatory frameworks'. Engineering Materials Live is a UK focused, specialist advanced materials event for design and production engineers.