Farnborough International Airshow

ATI – Destination Zero The Technology Journey to 2050

The Farnborough International Airshow 2024 hosts world leading innovators from aerospace, defence and beyond.

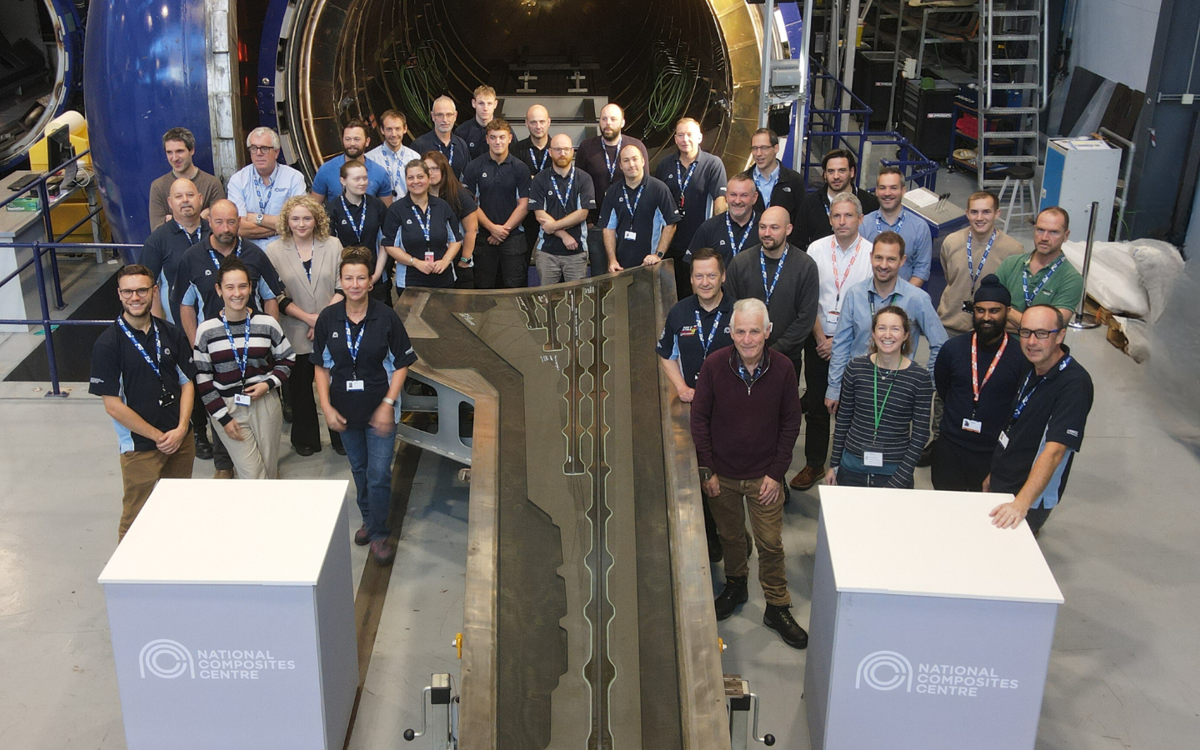

As part of the High Value Manufacturing Catapult, the National Composites Centre (NCC) is joining the Aerospace Technology Institute (ATI) at their technology showcase, taking visitors on a journey into the future of sustainable aviation.

Along with other HVM Catapult centres and NCC partners, we’ll be showcasing how our expertise in composite cryogenic hydrogen storage tanks is enabling net zero aviation. Trialled as part of the ATI FlyZero programme, the tank was designed, manufactured and tested with liquid hydrogen.

Book a tour to engage with our demonstrator at the ATI Stand 3501.

Our experts

The ATI theatre is hosting expert speakers from across UK industry to share the latest technologies, trends and insights powering advances in sustainable aviation.

Catch Kevin Mee, Head of Aerospace presenting “Accelerating innovation in composites for liquid hydrogen storage on future zero-carbon emission aircraft”, on Tuesday, 23 July at the ATI theatre (Hall 3, Stand 3501).

Kevin, and other NCC experts, will be available throughout FIA to share more about the NCC engineering capabilities and innovative solutions to meet your business needs:

- Jo Dally, Chief Business Officer, on Monday, 22 July

- Andrew Patterson, Head of Concept Engineering

- Adrian Tayler, Advanced Technology Programme Manager – Aerospace

- Krasimir Angelov, Associate Research Engineer

- Jakub Kučera, Advanced Research Engineer

Schedule time with our experts by emailing [email protected].

Alternatively, click 'Talk to the team' below, and complete the form.

Our work

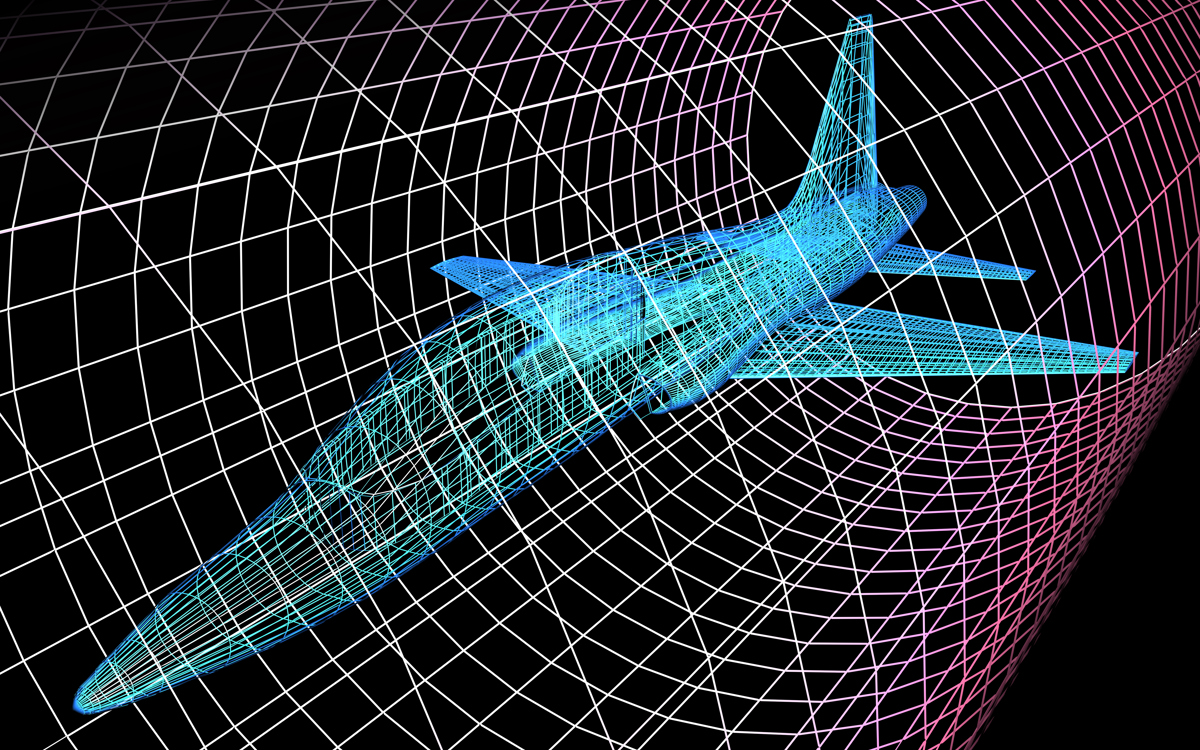

We are accelerating innovation for zero-emission aircraft using pioneering technologies developed at the National Composites Centre. Our work with primes explores radical new approaches to the design and manufacture of future wings – from significantly reducing assembled parts to collaborating on adaptable wing technology to improve aircraft performance.

NCC has tested a range of composite cryogenic storage tanks with liquid hydrogen that it has designed and manufactured to support the UK’s transition to the hydrogen economy.

NCC supports Airbus’ innovative project to optimise wing aerodynamics and aircraft performance through hinged wingtips inspired by the biomimicry of seabirds.

NCC’s expertise significantly contributed to the development of critical components for the VX4 electric aircraft prototype, and de-risking their path to certification.

NCC achieves the world’s first full scale 17-metre integrated wing skin infused in one step.

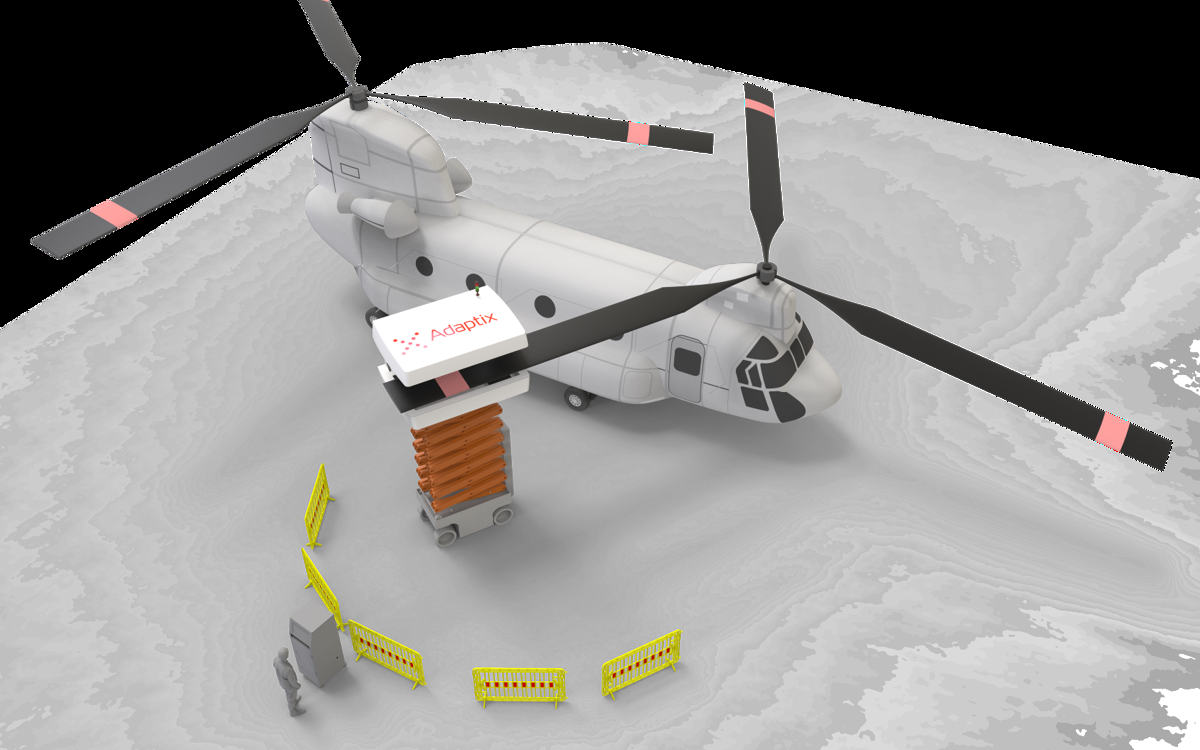

NCC helps UK SME extend medical imaging expertise into non-destructive testing (NDT) for the aviation industry, with the potential to break into a market estimated at £1.5 billion annually.

Our capabilities

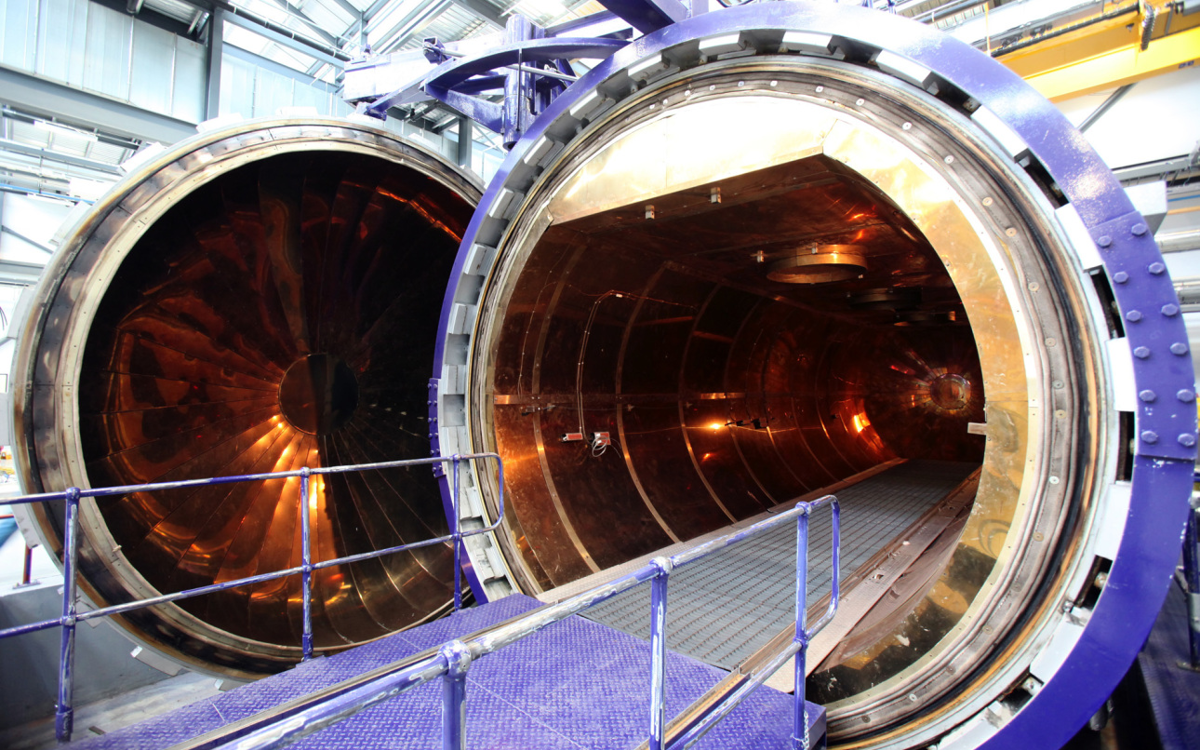

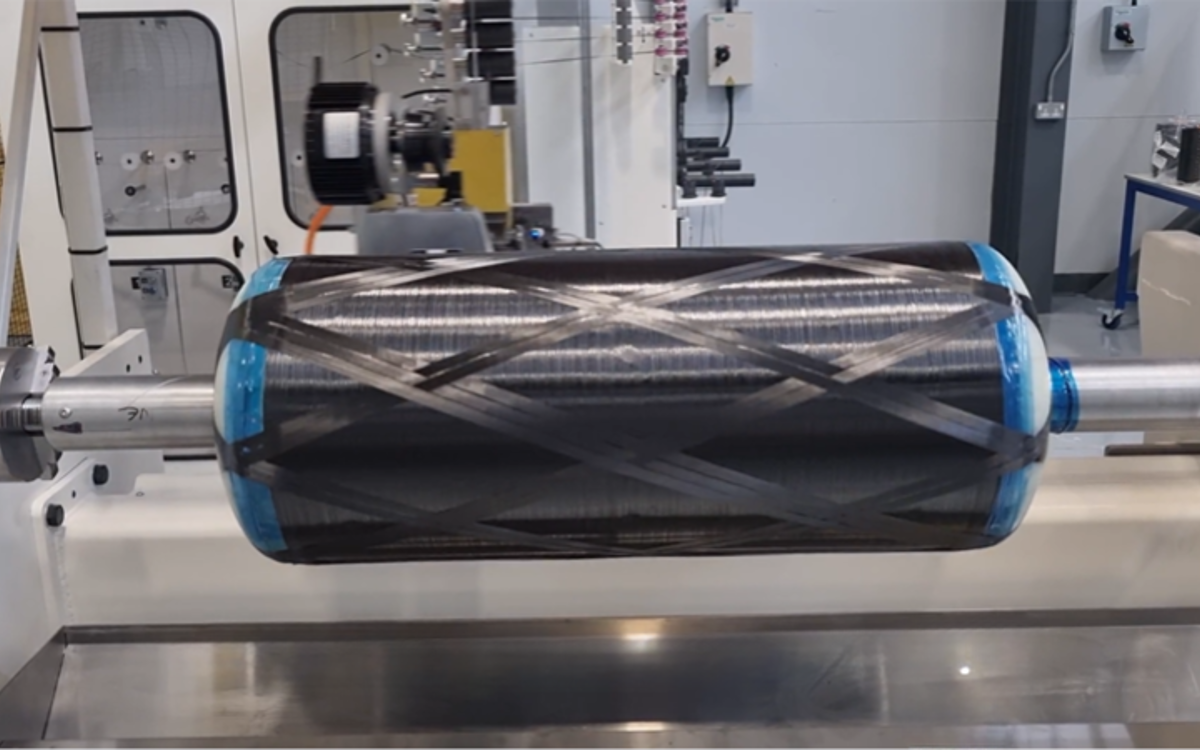

Our tape winder and filament winder machines can create anything from high-strength pipes to high pressure type 4 hydrogen tanks. Our twin-ring braider can create components that are hollow and straight or complex cross sections with curved profiles.

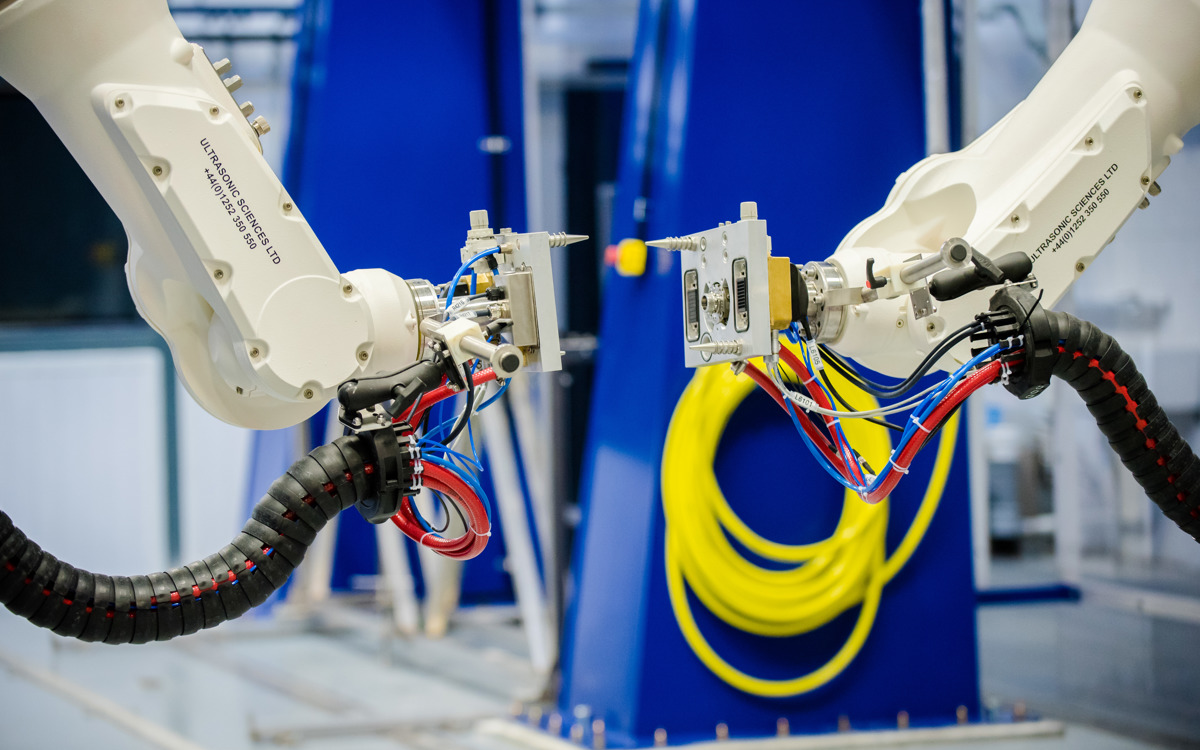

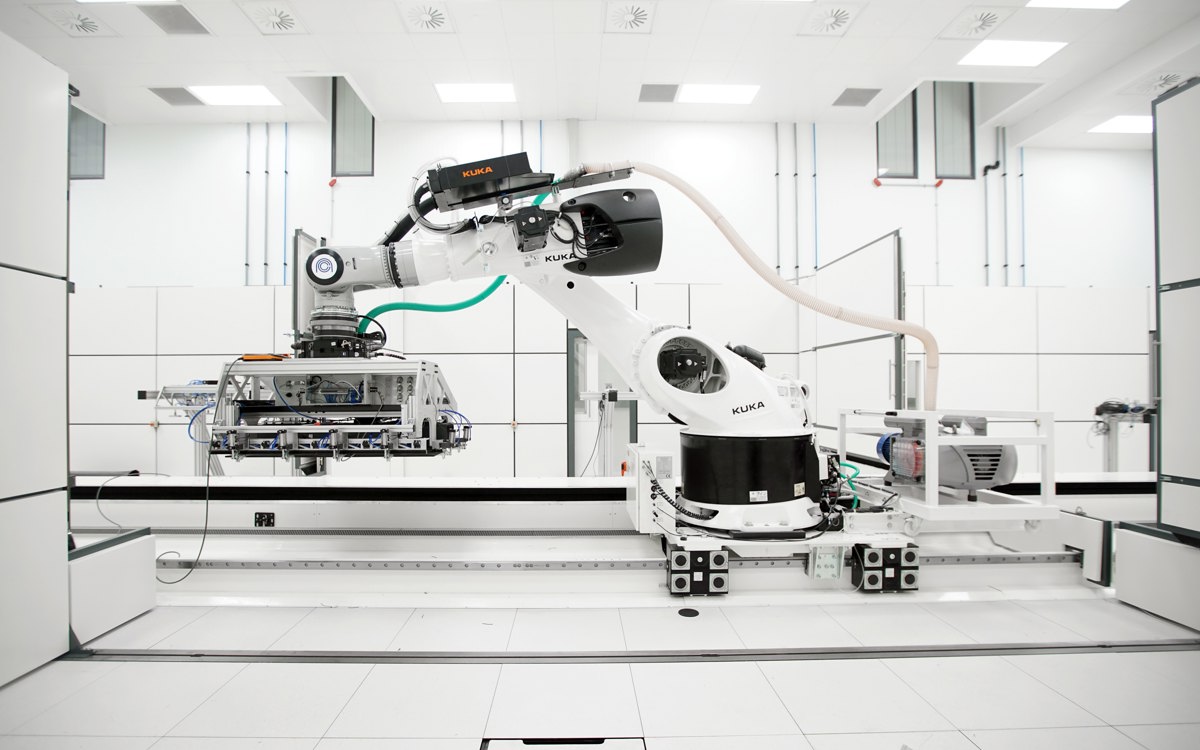

Our Ultra High Rate Deposition cell contains two huge industrial robots that automate the production process for future large scale, high rate composite products such as wings and turbine blades.

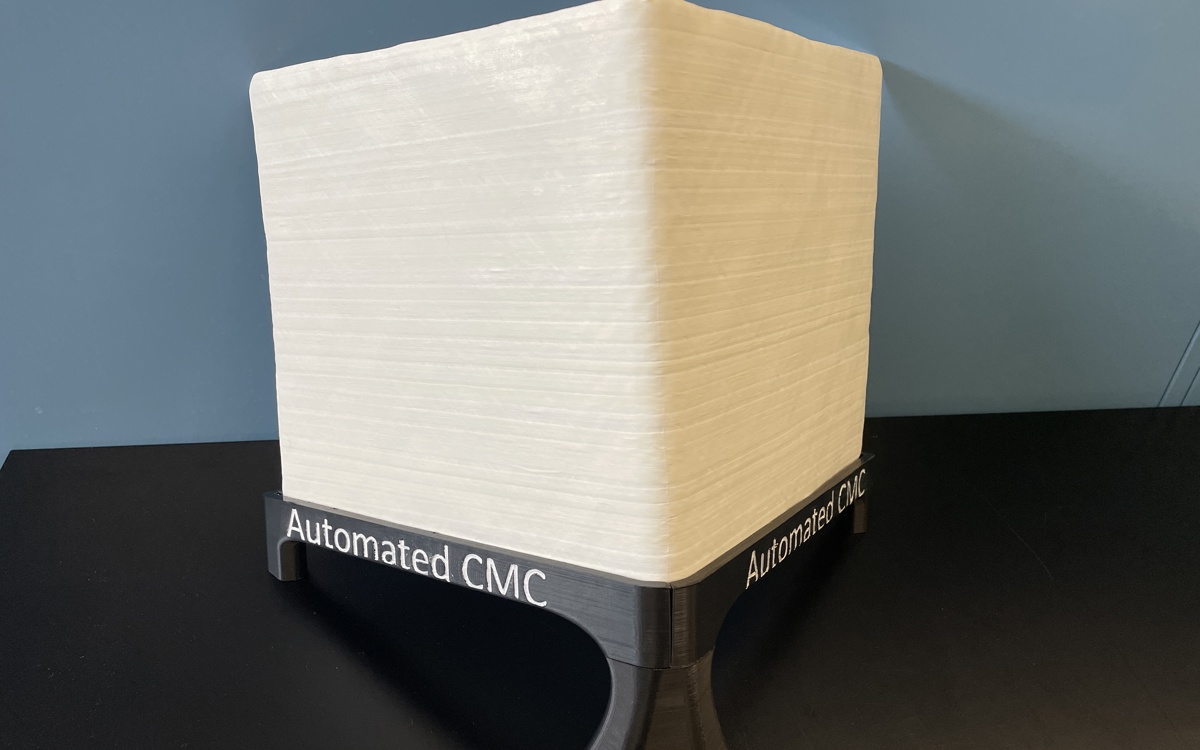

Our bespoke ceramic matrix composite (CMC) development facility includes material storage and processing equipment specifically for CMC applications, including aircraft propulsion.

We are the best equipped research centre for automated fibre placement (AFP), tensioned fibre placement (TFP) and automated tape laying (ATL) in the world.

We have a suite of verification capabilities across non-destructive testing (NDT), metrology, and a materials testing laboratory to assess the quality and performance of a material or product.

In addition to a range of specific automated manufacturing technologies, the NCC has a dedicated automation cell predominantly used to create fast, repeatable, complex parts. Our fixturing capabilities allow us to bond high precision parts into a safety critical assembly.

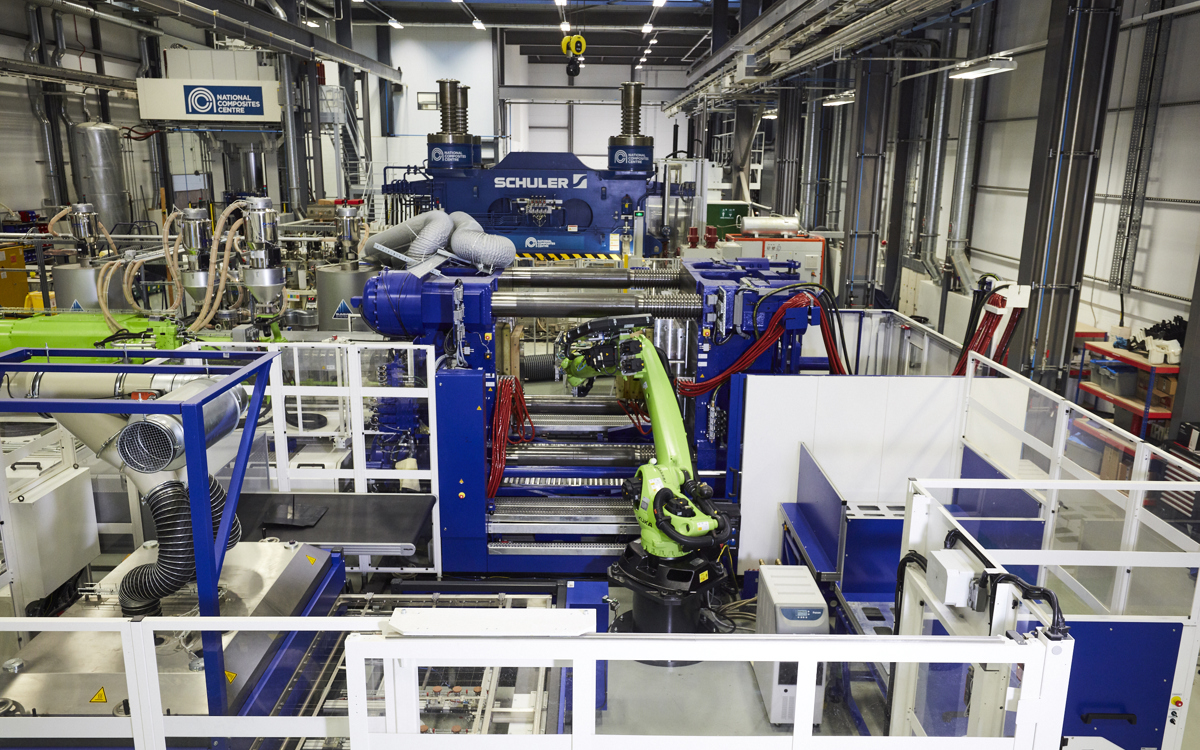

Our dedicated high volume manufacturing workshop is equipped with a range of presses, including our 3600T Schuler, and a state-of-the-art injection overmoulder capable of producing complex and repeatable parts in sub 5 minute cycle times.

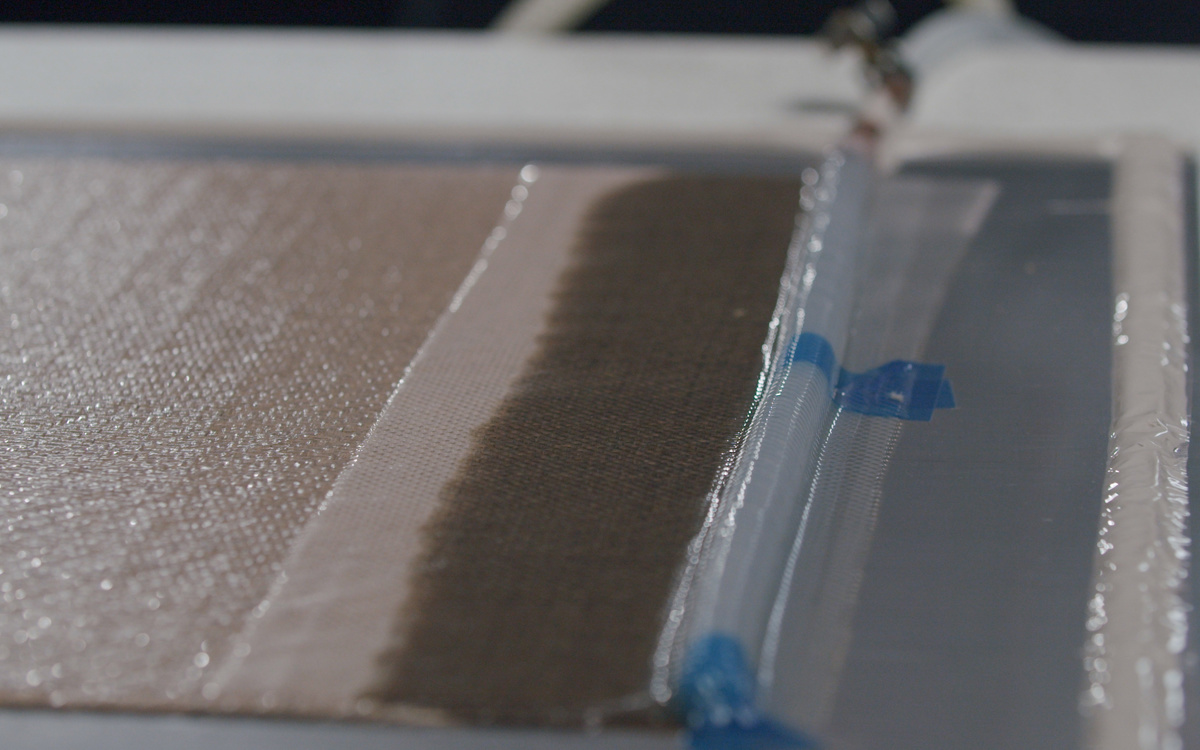

We have an array of resin infusion and resin transfer moulding capabilities that allow us to manufacture parts from 10s of millimetre up to 20 metre scale, and process materials at a range of temperatures and pressures.

We have a wide variety of composite curing and assembly capabilities ranging from an oven or autoclave big enough to handle an aircraft wing to the fixturing and skills required to bond high-precision parts into a safety critical assembly.