Newsletter Issue 7

Welcome to the latest edition of our newsletter.

As the UK’s world leading composite research and development facility, we’ve been forging ahead in the fields of composites, digital engineering, hydrogen, and sustainability.

The National Composites Centre's core research and development efforts are focused on fostering innovation, uncovering new opportunities, and empowering UK companies of all sizes to solve the world's most complex engineering challenges.

In the latest edition of our newsletter, we delve into our latest news, thought-provoking opinion pieces, and impactful case studies, sharing our professional training opportunities available in the coming months.

News Highlights

- We’re delighted to welcome three new Non-Executive Directors, bringing invaluable expertise to the National Composites Centre.

- We’re working to establish expertise in the accelerated design, test and manufacture of composite cryogenic systems.

- We’re launching a joint industry project (JIP) on thermoplastic composite pipes (TCPs) for hydrogen distribution and material selection.

- We’re collaborating with UK Atomic Energy Authority in progressing the development of Ceramic Matrix Composites.

- We're hosting a new supercomputer for artificial intelligence (AI) and high-performance computing.

To engage or collaborate on the programmes and innovations we have shared, email: [email protected]

Latest News

From supercomputers and the launch of Space West, to opportunities and breakthroughs in hydrogen and nuclear, we have a wealth of information to share.

The NCC is delighted to welcome three new Non-Executive Directors. Dr Deborah Allen, Zoe Barnes and Dr Ruth Mallors-Ray have a wealth of experience spanning multiples sectors, and will offer independent challenge and guidance to the NCC to ensure it achieves its strategic objectives in enabling UK industry to thrive and meet the net zero challenges.

Lucideon and the National Composites Centre (NCC) have forged a closer collaboration to develop advanced ceramic composites solutions to meet a growing market demand for materials that survive in ever harsher environments.

The NCC celebrates the achievements of a group of talented work experience students who recently embarked on an engineering adventure within its facility in Bristol.

The NCC is launching a joint industry project that focuses on the permeability of thermoplastic composite pipes (TCPs) for hydrogen distribution and optimal material selection for relevant applications.

The NCC is pleased to announce that it will be supporting the UK Atomic Energy Authority (UKAEA) on the HASTE-F programme, sharing knowledge and expertise in the application of Silicon Carbide Ceramic Matrix Composites (SiC/SiC) in future fusion power reactors.

Graduate Engineers from the National Composites Centre (NCC) were inspiring the next generation recently in celebration of British Science Week.

The High Value Manufacturing Catapult is releasing new tools to accelerate the UK’s capabilities in Certification by Analysis, and help engineers and manufacturers cut development costs and time to market for products.

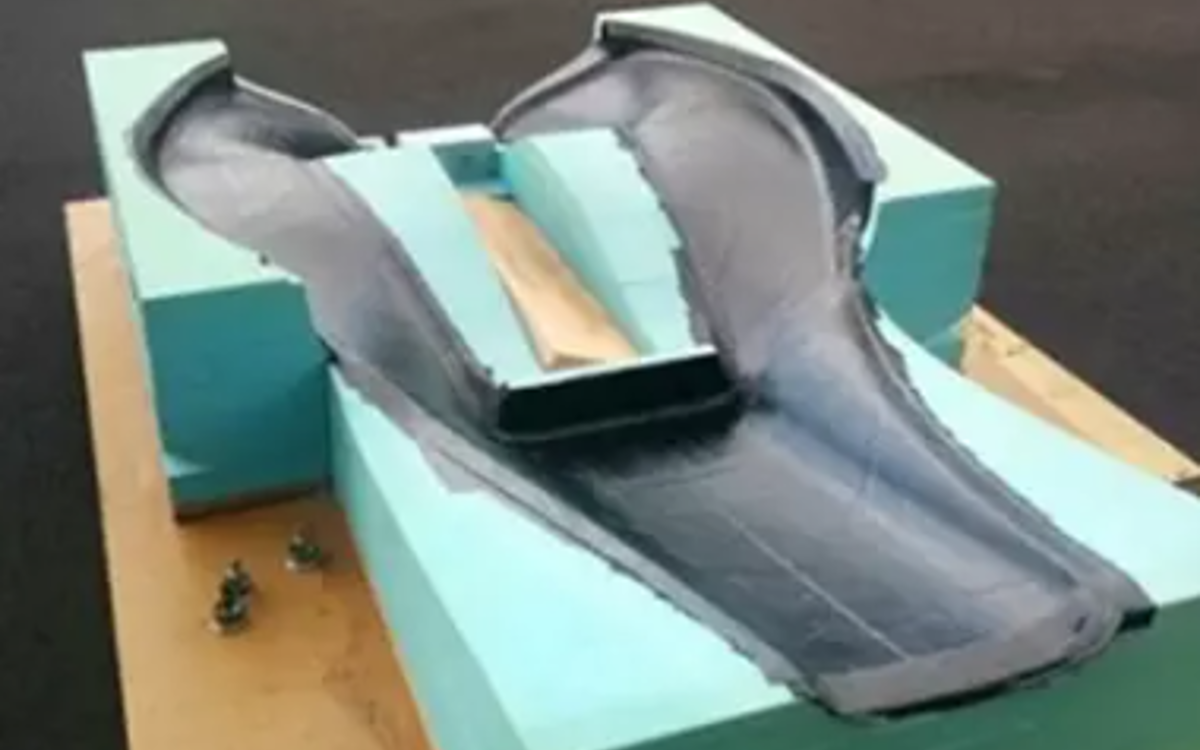

Composites UK has officially launched the latest in its series of good practice guides. Co-funded by the National Composites Centre, this latest edition focusses on Mould Tooling for Fibre-Reinforced Polymer Composites.

The National Composites Centre will play a key role in the EU-funded REFORM project, which seeks to become the catalyst for the creation of a green functional electronics supply chain that could replace metal and copper wiring in electronic devices and appliances.

NCC announces a UK-based composite cryogenic storage tank testing programme that will validate and accelerate design, manufacture, and test capabilities, starting with a linerless carbon fibre tank for storing liquid hydrogen (LH2).

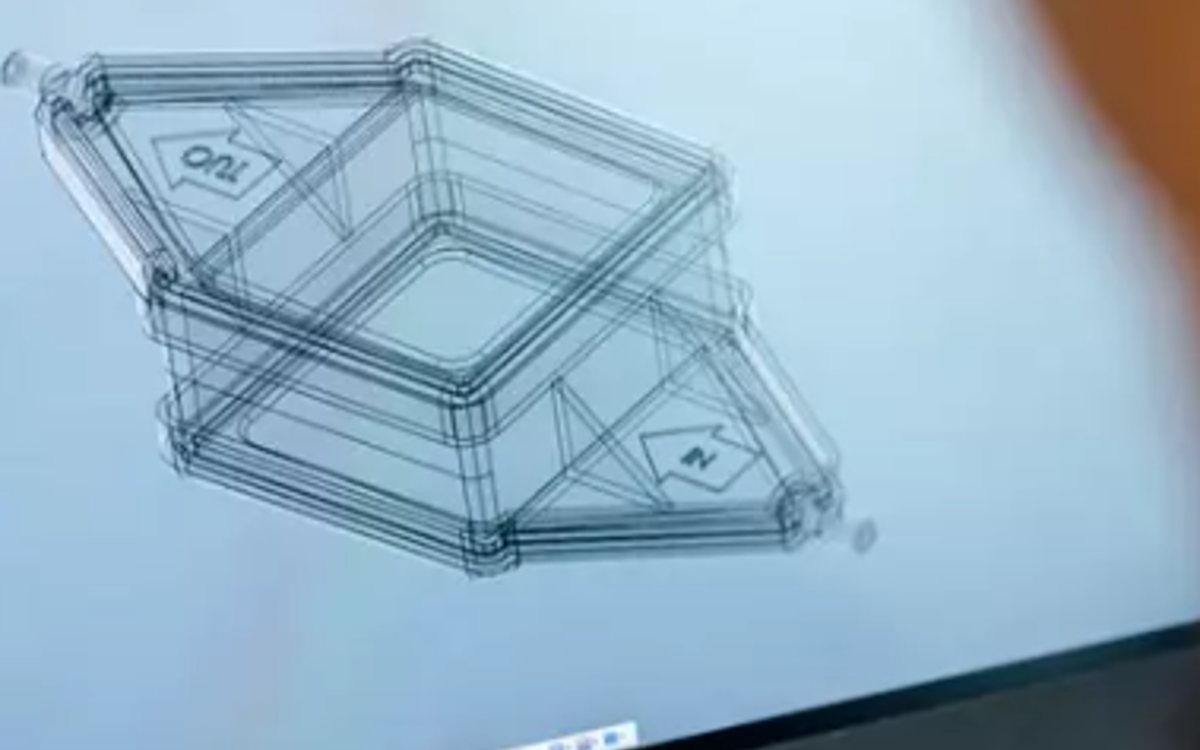

The NCC announces the creation a unique concept design tool that optimises hydrogen cryogenic tank designs according to a customer’s specific requirements.

The HVM Catapult has launched a series of open access awareness modules to increase understanding of hydrogen across multiple sectors and stimulate the UK’s transition to a hydrogen-based economy.

E4tech, an ERM Group Company, has conducted market analysis to quantify the UK industrial composites opportunity as it relates to hydrogen technologies.

The UK’s GW4 Alliance, which brings together the universities of Bath, Bristol, Cardiff and Exeter, together with Hewlett Packard Enterprise (HPE), NVIDIA and Arm, have been awarded £10 million by UKRI to develop Isambard 3, a new, TOP500-class supercomputer service for AI and high-performance computing (HPC) which will be hosted at the National Composites Centre.

The completion of the first phase of a major digital research, skills and innovation initiative in the West of England continues to see the South West define the next frontier of engineering.

A whole life-cycle approach is required to make the UK’s £4billion composites industry more sustainable, a new report has found.

The West of England Space Hub consortium launched as ‘Space West’ will be making its debut at the UK Space Agency’s Ignite Space event at Aerospace Bristol.

Calling UK SME manufacturers.

Have you heard about the High Value Manufacturing Catapult Energy Toolkit? We're helping SMEs to measure and identify ways to reduce their manufacturing process energy consumption, costs and greenhouse gas emissions.

Click the image to find out more.

Catch up on other news and announcements from across the business.

Case Studies, Impact and Opinion

Our core research and development strategy plays a key role in innovation, uncovering new opportunities, and fostering competitive advantage to help UK companies to build sustainable products and services. Here, we have shared a small selection of the most recent case studies, innovation impacts and opinion articles from our teams.

As the transition from fossil fuels to a hydrogen (H2) economy accelerates, so does the need to repurpose the existing network infrastructure to transport H2 from generator to consumer. It’s in this context that using composite pipes can help unblock both economic and technical barriers. The NCC has invested in developing its capability and knowledge of manufacturing thermoplastic reinforced piping to support the energy industry on its journey to a hydrogen economy.

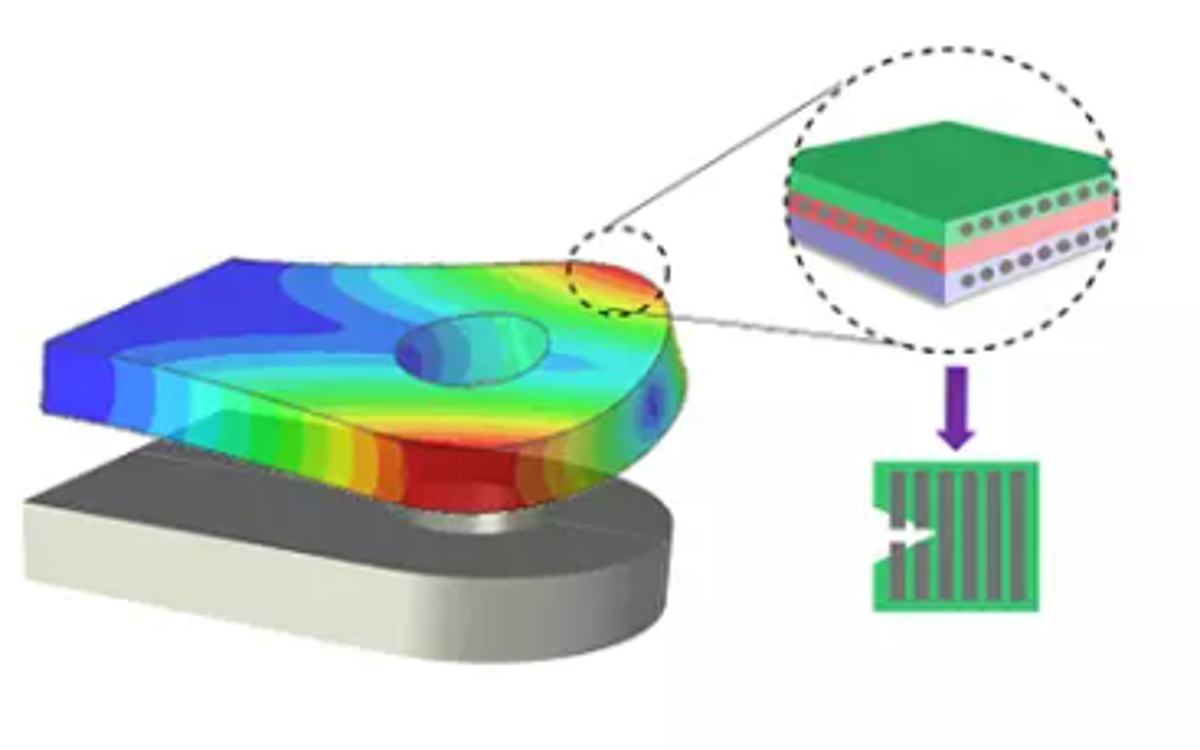

The National Composites Centre helps UK smart textile innovator Footfalls & Heartbeats develop a revolutionary new knitted composite sensor with the potential to optimise the value retention of wind turbines in support of more sustainable renewable energy sources.

University of Bristol (UoB) spin-out LMAT Ltd provides design and compensation of tools for composite production. They work closely with the aerospace, wind energy and automotive industries to improve composite production methods and overall product quality.

The National Composites Centre helps UK SME Adaptix Ltd extend medical imaging expertise into non-destructive testing (NDT) for the aviation industry, with the potential to break into a market estimated at £1.5 billion annually.

The NCC worked with micro-company Limosaero Ltd to develop a simplified, scaled-down demonstrator of their solar-powered, long-endurance, low-altitude uncrewed aerial vehicle (UAV) designed to offer a low-cost, zero-emissions way to carry out atmospheric and earth-observation over marine and land environments.

Vertical Aerospace's Electric Vertical Take-Off and Landing (eVTOL) aircraft, the VX4, is designed to transport a pilot and up to four passengers, over 100 miles, at a top speed of over 200mph, while producing minimal noise and zero in-transit emissions.

Micro-enterprise Actuation Lab has developed the world’s first industrial-grade origami-inspired actuator with the potential to relieve at least £368 million in automated machinery maintenance backlog within the UK's energy industry alone.

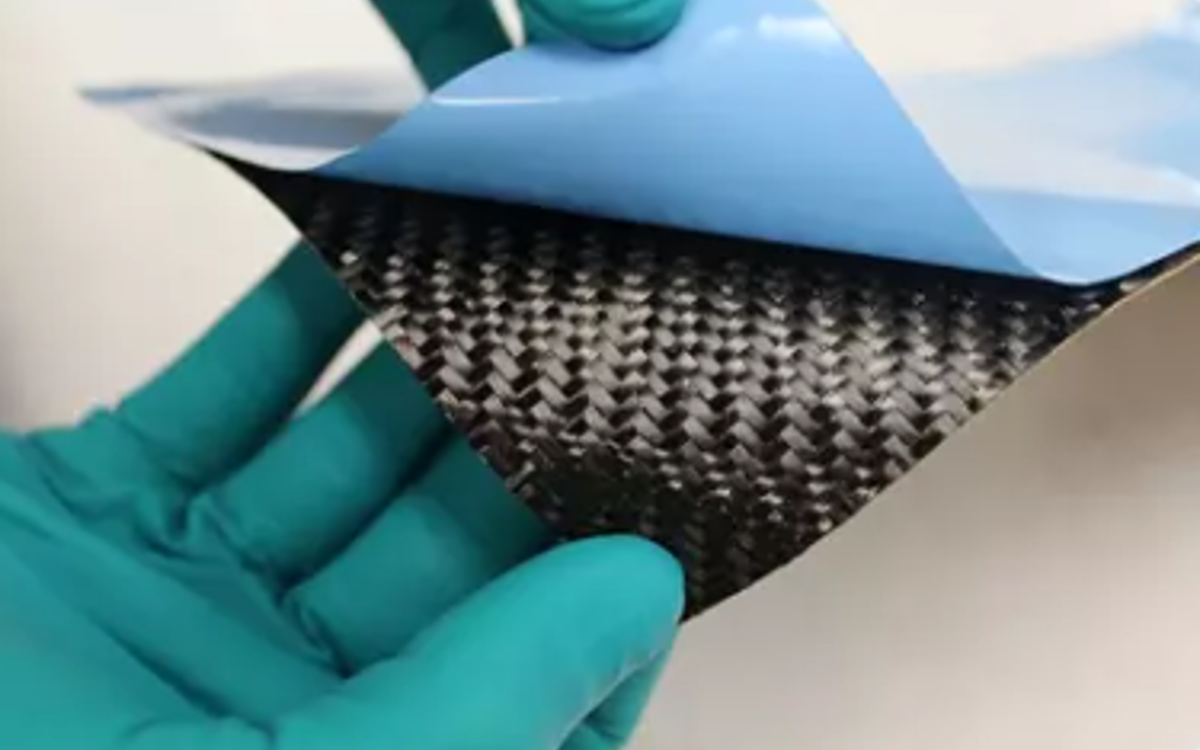

The NCC and the Defence Science Technology Laboratory (Dstl) collaborate on the latest technologies for the next generation of lightweight, strong and resilient combat aircraft composite structures.

Tim Young, Head of Sustainability, at the National Composites Centre, talks to The Engineer about the role of sustainable composites as a critical enabler in delivering a secure and sustainable future, and the opportunity for chemistry-enabled composites.

Marc Funnel, Chief Engineer for Smart Design at HVM Catapult and Head of Digital Engineering at the NCC talks about evaluating approaches, and addressing barriers, to accelerating certification by analysis here in the UK.

Marc Funnell, Chief Engineer for Smart Design at the HVM Catapult and Head of Digital Engineering at the NCC, talks about the opportunity to lead and accelerate pathways to product certification by developing new UK and potentially global standards that encourage the use of ‘certification by analysis’ techniques.

New hydrogen awareness training will help ensure the UK can overcome any challenges in our net zero transition. Read how we're approaching this in an article by Katy Riddington, NCC's Transformation Services Director.

Fusion energy promises nearly boundless, sustainable power. In recent years, many advances have been made that have the potential to unlock this almost limitless source of low carbon energy. Read the article by Dr Peter Giddings CEng MiMechE, NCC's Chief Engineer of Energy.

Interest in cryogenics is booming, aerospace and energy companies recognise the importance of hydrogen as we race towards Net Zero. Read our blog by NCC's Marcus Wall-Bruck, Head of Hydrogen Technologies, and Matt Kay, Principle Research Engineer, Hydrogen.

The energy transition is here. What role will energy companies, businesses and governments play in reaching Net Zero? Dr. Enrique Garcia, Chief Technology Officer at the NCC, took part in the Powered by How Podcast recently, discussing the role non-metallics can play in building a more sustainable future.

How do we deliver a step-change in the volume of composite material we can deposit at any given time? It is one of the key challenges we’re tackling at the NCC – and we’ve made significant progress. Read our blog by Mark Bowering, NCC’s Chief Engineer for Civil Air Structures.

Professional Training Opportunities

Elevate your expertise with our diverse range of training courses. Choose from various subjects and flexible delivery methods, including self-paced online learning, interactive virtual classrooms, or hands-on sessions at our state-of-the-art facility. Get ready to take your skills to the next level.

If you are new to composites, a basic knowledge of their composition and manufacture is essential to begin your journey. In this foundation level course we'll introduce you to the terminology, the materials, their properties and the production processes used in the composites industry.

This course provides an introduction to how businesses can start thinking differently about their operation, products and production processes in order to meet new legislation and support the drive for change.

If you're new to designing composite materials this course will give you the tools & techniques you need to confidently develop robust concept designs.

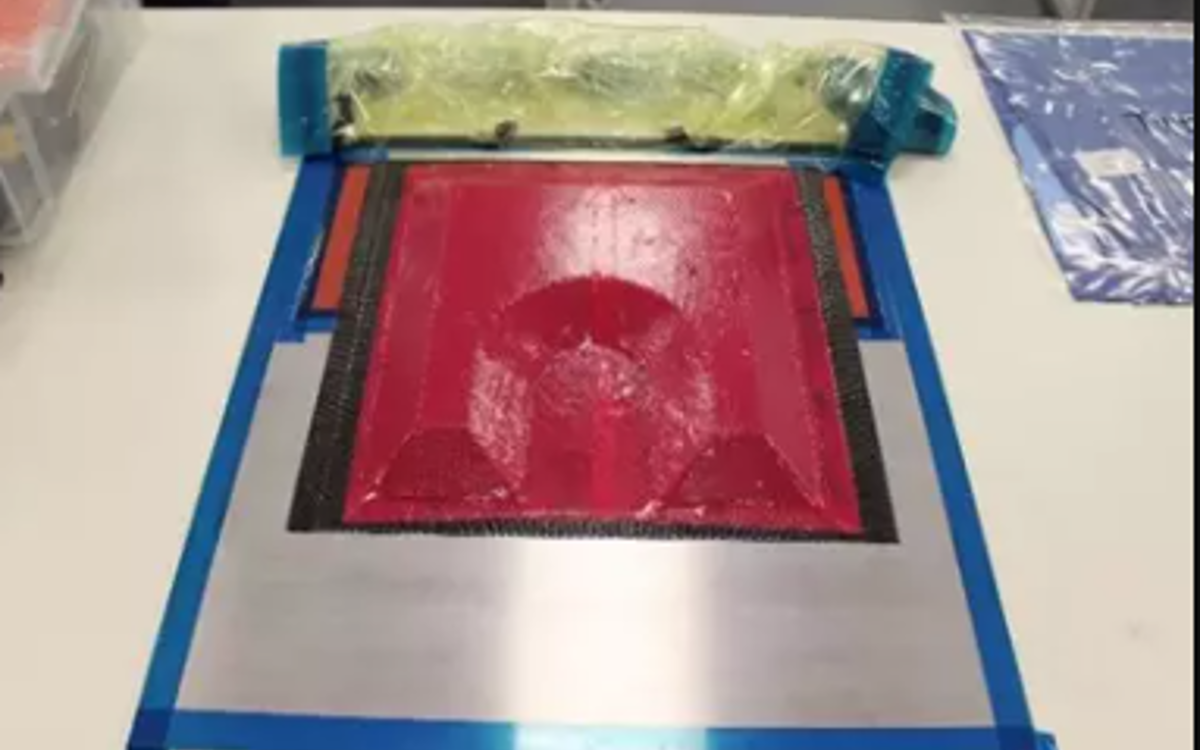

If you're a Technician who's new to using resin infusion for composites manufacture, this course will provide you with the skills and knowledge to avoid common mistakes and safely produce better parts.

Whether you're moving into prepreg manufacturing or work in an environment where it's already used and want to broaden your skills, this course will give you an essential introduction to materials and processes along with their application.

This two-day course is highly recommended for individuals and teams who are already producing prepreg parts and want to improve their processes and the quality of their finished products.

The seven centres that make up the High Value Manufacturing Catapult (HVM Catapult) have come together to create 'Hydrogen awareness: make it; move it; use it’, a series of open access online modules for all manufacturing sectors.

The NCC has joined with Queen’s University Belfast and Ulster University to support the re-launch of the Northern Ireland Advanced Composites and Engineering Centre (NIACE).

If you need to focus on improving the strength and stiffness elements of your composite designs this course will give you a knowledge of composite properties and an understanding of how each of the plies effect the global part.

This is a highly pragmatic introduction to repairing composites. We'll introduce the fundamentals of the topic and give you a solid understanding of the key principles.

Built using our wealth of knowledge and experience, this course is designed to introduce you to cutting edge technologies as well as teach you the fundamentals of composites joining techniques.

As an engineer who is currently responsible for measuring and inspecting metalics, and are now moving into the world of composites, this course will give you the tools and knowledge you need to ensure that you understand the different challenges composites present and the techniques they require.

If you're looking to implement automated processes into your existing composite manufacturing activities this course will give you the knowledge you need to explore and assess techniques to take your production to the next level.

This is a highly practical course, which will teach you cost-effective ways of producing your own moulding from scratch. You'll gain the knowledge you need to produce quality parts and learn how to avoid common errors.

Events for your diary

Mark your calendars for upcoming events where you can connect, collaborate, and engage with us. Whether it's in-person or virtual, we can't wait to meet you there.

Organised by Composites UK and Fluency, ICS brings together leading industry professionals to address the worldwide opportunities for sales and growth within the composites sector, needed to help deliver the climate change targets set out in each nation's green agenda. We're on Stand L16.

Visit the NCC at Cenex LCV (Stand C3-501) to discover how composites is enabling the UK's net zero future through innovation. Our team will be on hand to talk through some exciting projects and research developments.

DSEI connects governments, national armed forces, industry thought leaders and the entire defence & security supply chain on a global scale.

As engineering inevitability moves into the digital era, it continues to face challenges around simulation and modelling. There is a huge pressure on companies across all industries to move towards total simulation and digital testing in order to avoid the heavy costs associated with physical testing and the building of physical prototypes.

For our next Technology Day, we’re diving deep into the realm of joining composites in Defence applications. This event is a unique opportunity for academics, the supply chain, and experts in the field, to come together and explore the cutting-edge world of composite materials. Join us as we unlock the potential of these advanced materials and their integration into the Defence sector.

This Technology Day will encompass a comprehensive range of topics related to composite joining techniques, ensuring that the Defence industry stays at the forefront of innovation.

Themed ‘Be inspired by Innovation’, the 14th edition will celebrate innovation, collaboration and sustainability within the engineering and manufacturing industries. Explore related opportunities by visiting the NCC at Stand T120.

Space West will be attending The UK Space Conference at the ICC Belfast, taking place 21st - 23rd November 2023.

Don't miss out on other events.