NCC Newsletter Issue 9

Welcome to the latest edition of our newsletter.

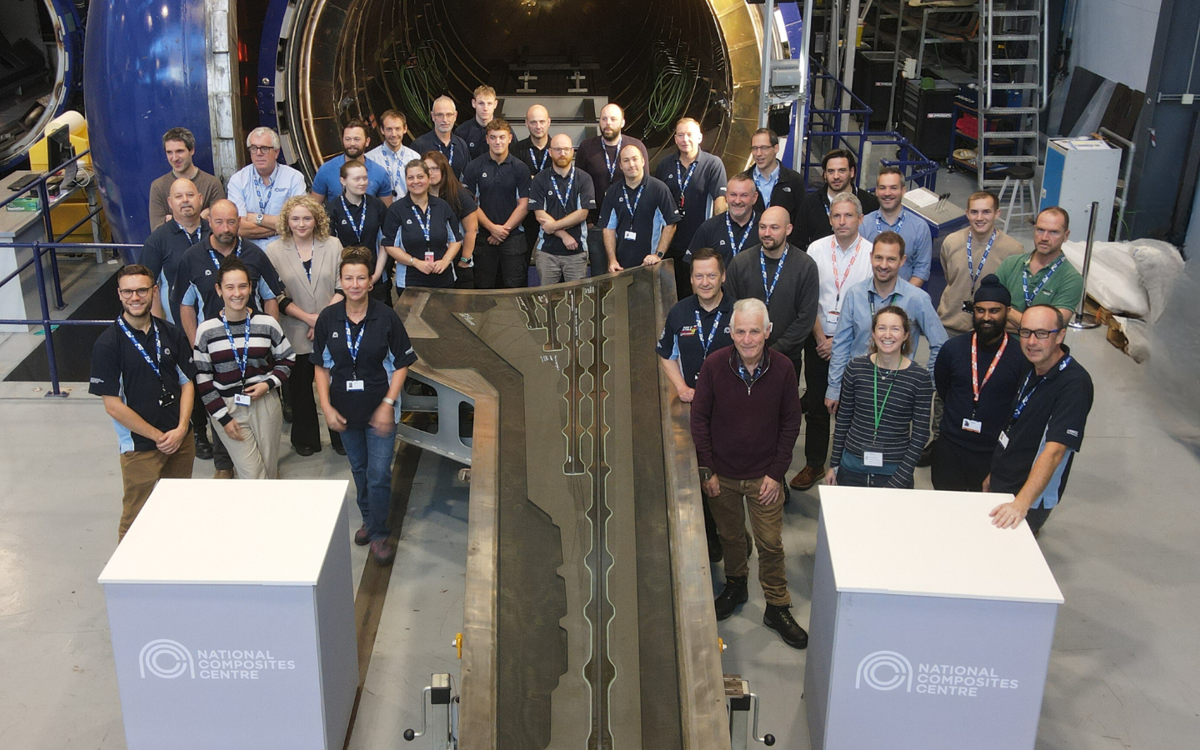

At the National Composites Centre (NCC), we're dedicated to tackling some of the world's most complex engineering challenges by uniting top talent with cutting-edge technologies. From aerospace to construction, and energy to space, our mission is to drive industrial transformation and foster sustainability across diverse sectors.

In this edition of the newsletter, you can find our latest news, case studies, reports and details of our professional training opportunities available in the coming months.

We were honoured to kick off 2024 by hosting Sir Keir Starmer MP’s New Year speech. In his address, Sir Keir emphasised the importance of being ‘mission-driven,’ a sentiment that deeply resonates with our commitment to leveraging composite technologies, digital engineering, and sustainability leadership to address local, national, and international challenges.

In exciting news, the NCC has recently released its Impact Report, showcasing our significant contributions to the UK over the past five years. Through technical innovations, supply-chain interventions, and workforce initiatives, we've generated £59 million in direct economic output annually, with £40 million benefiting the West of England region.

One of our standout initiatives involves collaborating with Sonichem on the groundbreaking CARMA project. This venture marks a pivotal step towards sustainable alternatives in materials and manufacturing in the automotive industry.

Additionally, our experts attended JEC World in Paris showcasing the industrial transformation that composites can offer through enabling sustainable opportunities towards a net zero future and we hosted an Artificial Intelligence (AI) in Engineering and Manufacturing workshop. This event provided an opportunity for delegates from across industry and academia to learn more about the potential of AI in engineering and manufacturing. If you’d like to be involved in unlocking the potential of AI, reach out to our digital experts.

Furthermore, we're proud of our continued work as part of the Hydrogen Skills Alliance (HSA), committed to building a skilled workforce necessary to support the growth and development of the UK hydrogen sector. Ensuring employers can access the talent needed to compete, innovate, and grow as we meet the demands of a changing energy landscape and deliver our net zero ambitions.

We invite you to explore these stories and more as we continue to drive innovation, foster collaboration, and deliver impact. If you’d like to join us over the coming quarter, check out our upcoming events.

To engage or collaborate with us, email: [email protected]

Latest News

From hosting Sir Keir Starmer to a High Performance Computing workshop, we have a wide range of news and updates to share.

The National Composites Centre (NCC) is delighted to share news of our involvement in CEAMS (the Centre of Expertise in Advanced Materials and Sustainability) which will focus on providing state-of-the-art green manufacturing solutions and bringing investment to Rochdale and the wider region.

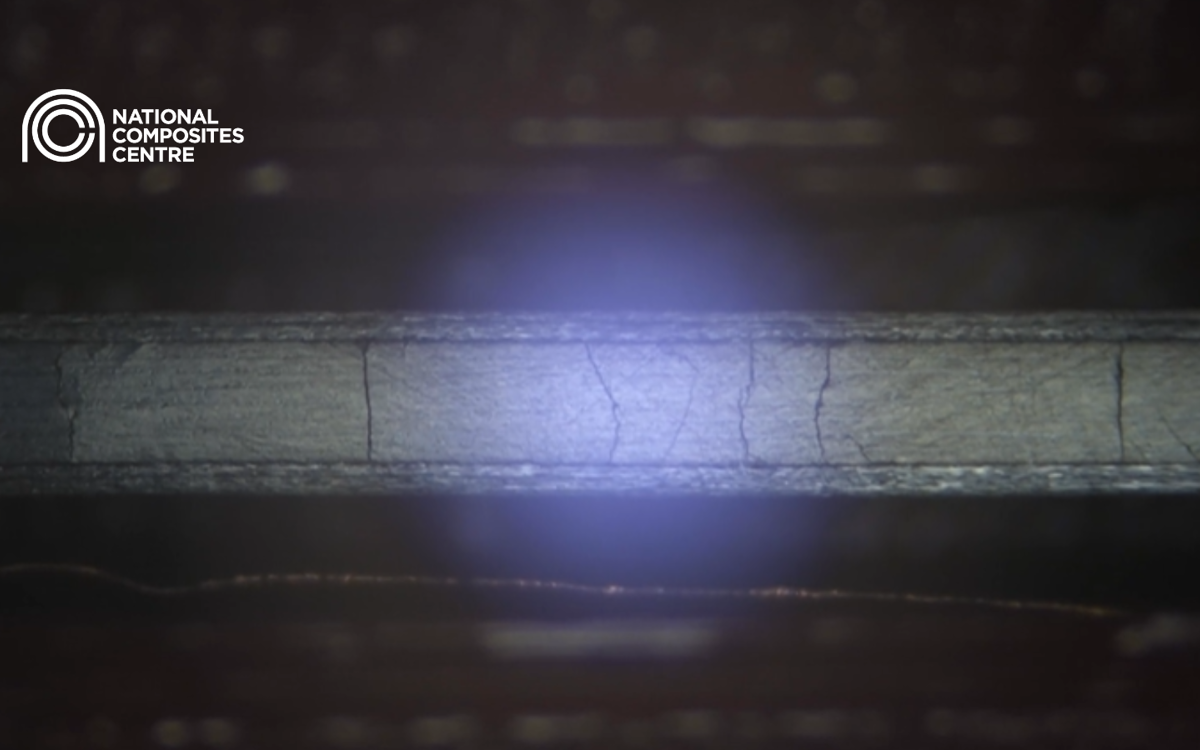

The National Composites Centre (NCC) has developed a novel cryostat and test method that allows the screening of composite material performance at cryogenic temperatures in an ultra-fast and cost-effective way.

The National Composites Centre (NCC), part of the High Value Manufacturing Catapult, exhibited at JEC World 2024 - the global trade show for composite materials and their applications.

Ahead of the Spring Budget the Chancellor Jeremy Hunt has announced a significant investment package in the UK’s life sciences and manufacturing sectors, as part of the government’s plan to grow the economy, boost health resilience and support jobs across the UK.

The National Composites Centre (NCC) is delighted to share news of our involvement in a cutting-edge project led by Sonichem, actively contributing to the shift towards sustainable alternatives in materials and manufacturing.

Learn more about the work the High Value Manufacturing Catapult has been doing towards advancing sustainability and innovation in manufacturing this year.

National Composites Centre is honoured to have hosted Sir Keir Starmer MP's New Year speech on Thursday 4 January 2024.

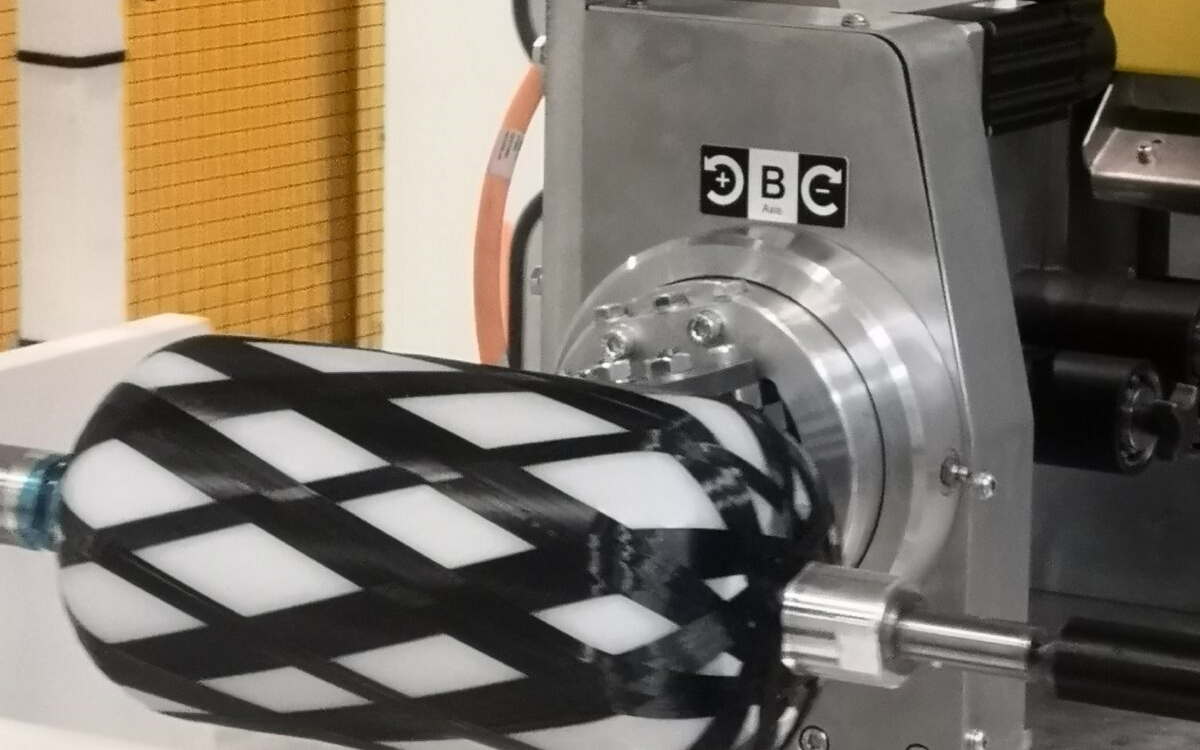

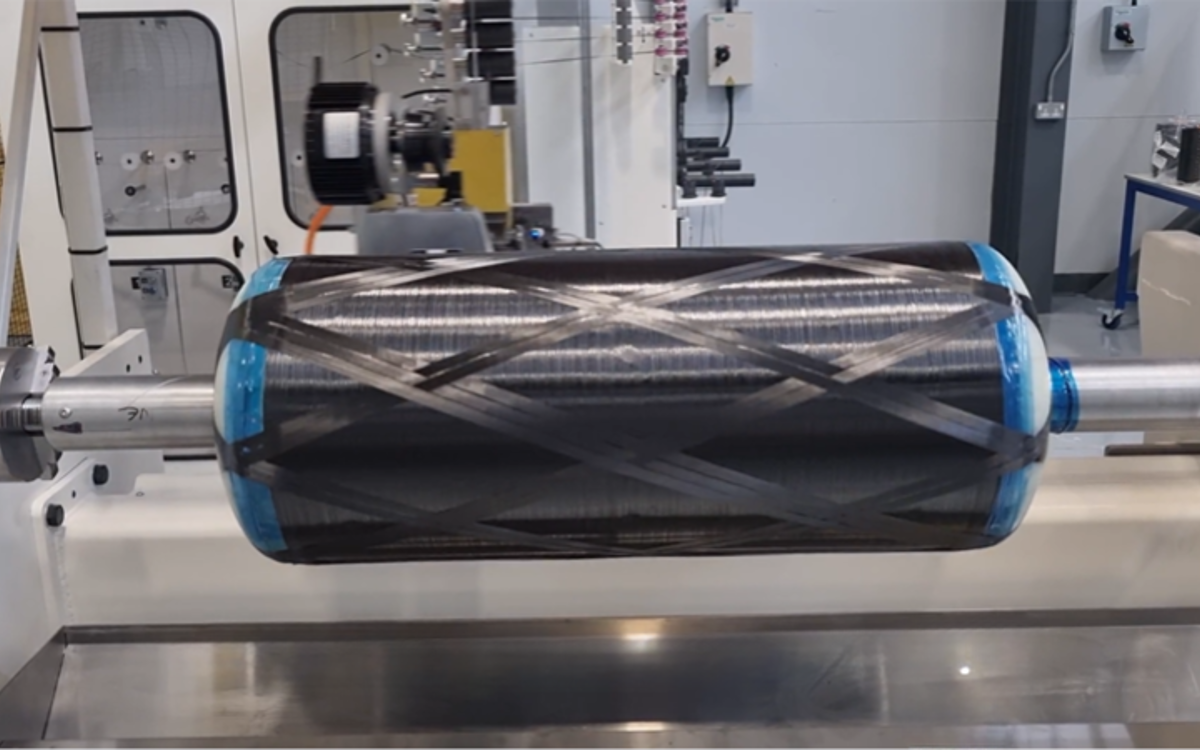

Composites technology company Cygnet Texkimp, Northwich, UK, has delivered a four-axis filament winding machine to the National Composites Centre where it will form part of a new state-of-the-art manufacturing and test facility for hydrogen transportation and storage.

The High Value Manufacturing (HVM) Catapult is delighted to be collaborating with the Welsh Government on a new digital factory hub to advance manufacturing technology innovation and support Wales’ green industrial transformation.

Case Studies, Impact and Opinion

Our core research and development strategy plays a key role in innovation, uncovering new opportunities, and fostering competitive advantage to help UK companies to build sustainable products and services. Here, we have shared a small selection of the most recent case studies, innovation impacts and opinion articles from our teams

The NCC engineers have successfully delivered the design and manufacture of vital one-off flying parts to facilitate UK’s capability towards accelerating new technologies to decarbonise the aviation industry.

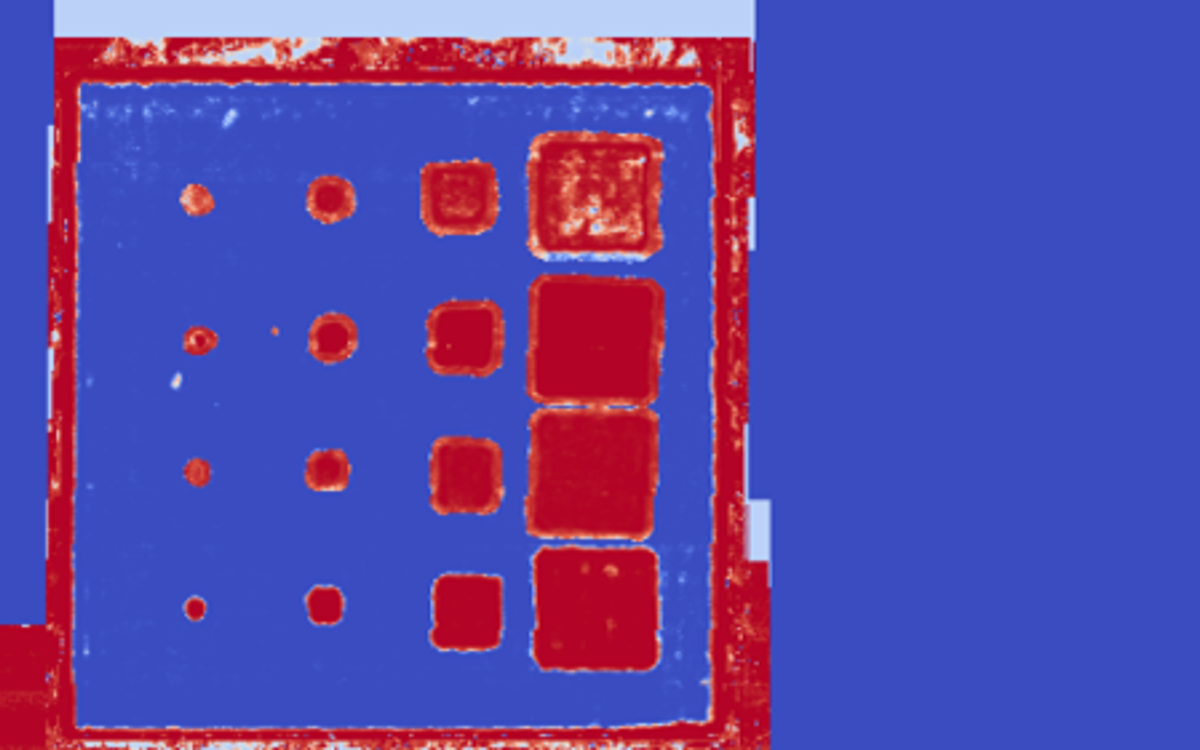

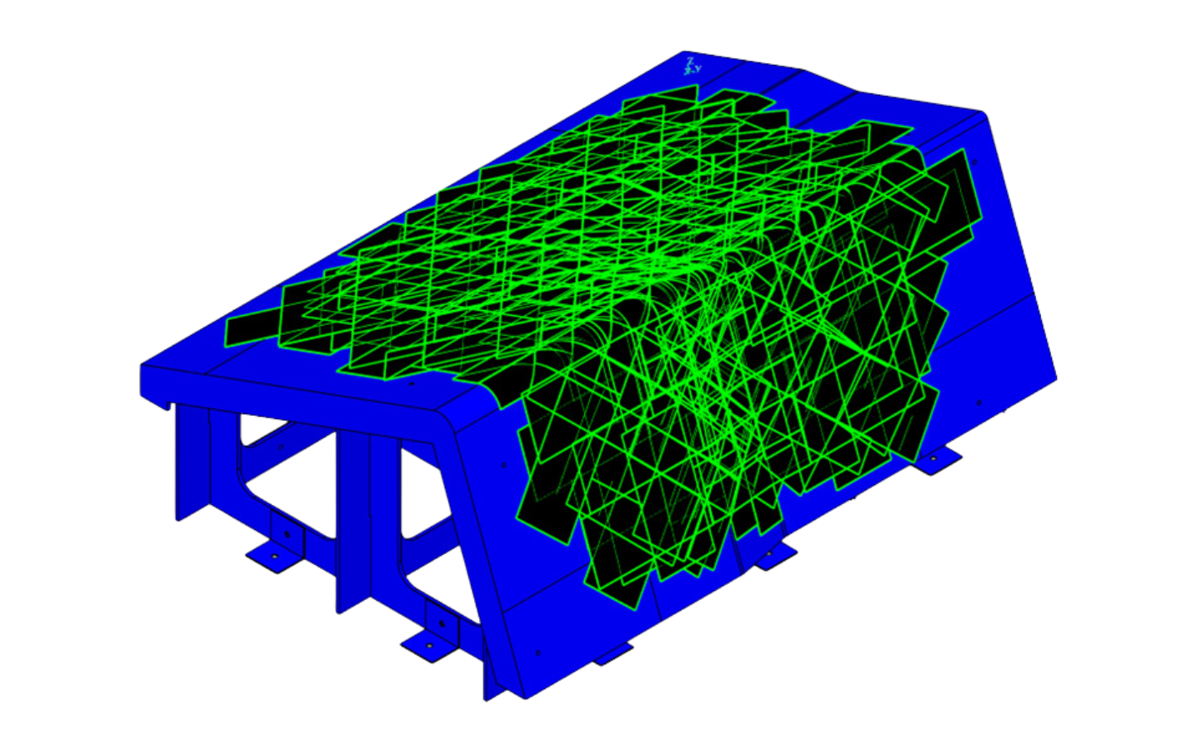

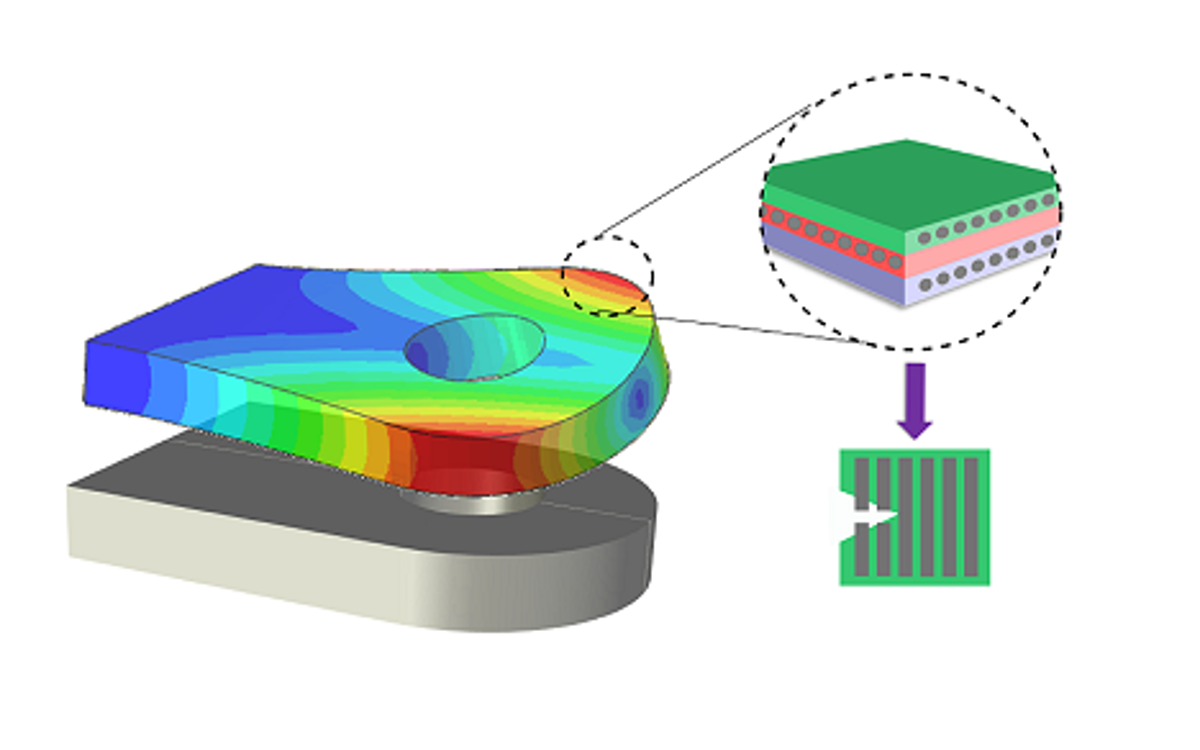

The NCC has successfully developed a proof-of-concept machine learning tool that has the potential to drastically speed up the analysis of non-destructive testing (NDT).

Engineers at the NCC along with British SME partners B&M Longworth Ltd and Cygnet Texkimp, have successfully reclaimed continuous carbon fibres from a whole pressure vessel and re-used them to manufacture a new pressure vessel. This represents a significant milestone in the development of Britain’s hydrogen capability.

Engineers at the NCC have successfully demonstrated the potential to recycle up to 80% of carbon fibre material from the earliest stages of aerospace manufacturing as alternative feedstock.

In an exciting collaboration, Sonichem, an innovative clean tech company, embarked on a transformative project with the Innovation Centre for Applied Sustainable Technologies (iCAST). This partnership aimed to harness the potential of lignin in developing advanced sustainable materials that offer an alternative solution to fossil-derived materials.

The NCC has released a report that evidences the impact it has delivered for the UK over the last five years. This includes driving industrial transformation through technical, supply-chain and workforce interventions and innovations.

The NCC is delighted that the gender pay gap has narrowed since the last report. It is even more positive that this has happened at the same time as an increase in the proportion of women in its workforce.

Watch the video which shows the NCC's new Filament Winder from Cygnet Texkimp, used to manufacture Hydrogen Pressure Vessels, part of its state-of-the-art design, test and manufacturing facility for Hydrogen.

Professional Training Opportunities

Enhance your skills with our comprehensive training programs. Immerse yourself in diverse subjects and flexible learning approaches crafted to suit your requirements. Step into the future at our cutting-edge facility and elevate your expertise. Don't miss our revamped 'Composite Joining Principles' course which compliments our Composite Assembly course. We continuously update our courses to provide the best learning experience.

The seven centres that make up the High Value Manufacturing Catapult (HVM Catapult) have come together to create 'Hydrogen awareness: make it; move it; use it’, a series of open access online modules for all manufacturing sectors.

Use of the correct joints is vital to creating highly functional composite structures. We highly recommend this course for composite designers who want to improve their approach to bonding and joining composite materials ensuring better results.

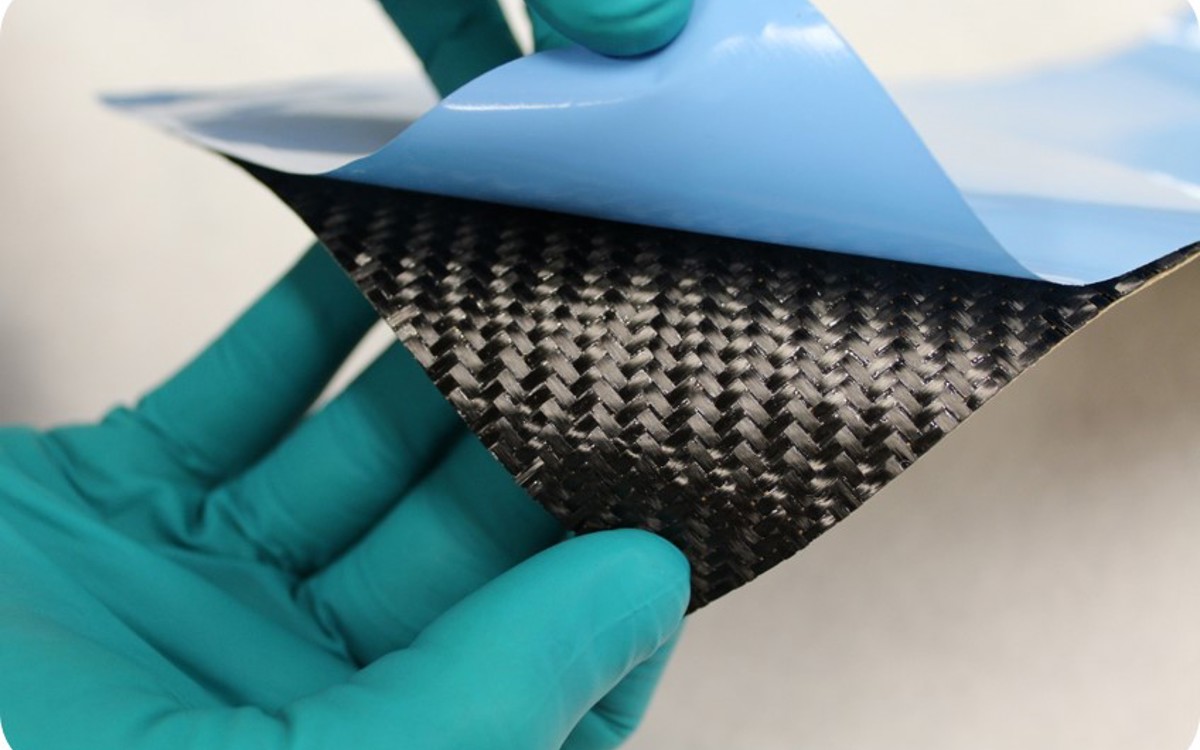

This course is designed to show you good practice for selecting joining methods and how to manufacture them correctly. The content is primarily practical, covering the use of surface preparation, bonding, and fastening with permanent and semi-permanent fasteners.

During this course we'll give you the background knowledge you need to optimise your use of prepreg materials in order to achieve the best possible outcomes. We'll also teach you the techniques used by technicians and you'll have the opportunity to practice what you've learnt.

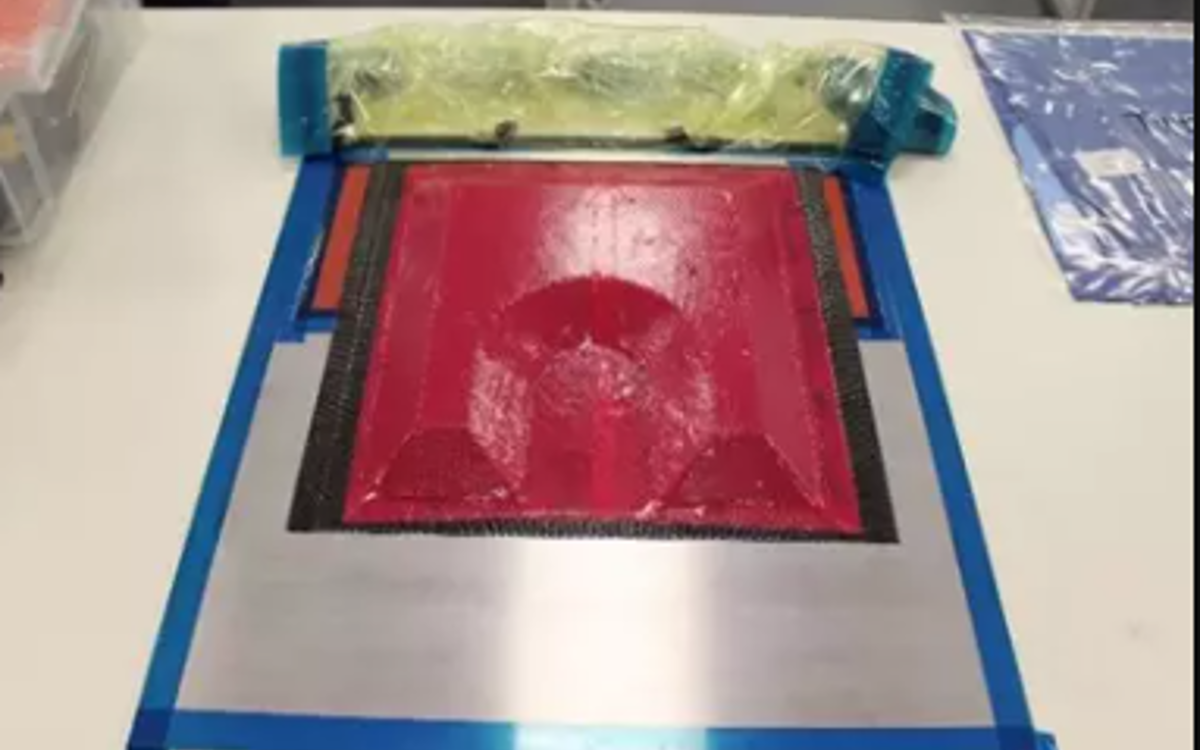

If you're a Technician who's new to using resin infusion for composites manufacture, this course will provide you with the skills and knowledge to avoid common mistakes and safely produce better parts.

Making simple components is straight forward, but if your making more complex parts then you need increased skill levels and advanced techniques. We'll cover many of the advanced techniques used by technicians at the high performance end of prepreg manufacture.

As a Technician or Engineer in the composites world you'll know that as the industry grows and matures there's an increasing need to maintain and repair in-service structures.

If you need to focus on improving the strength and stiffness elements of your composite designs this course will give you a knowledge of composite properties and an understanding of how each of the plies effect the global part.

If you're new to designing composite materials this course will give you the tools & techniques you need to confidently develop robust concept designs.

Or perhaps your business is making the shift from traditional materials to composites and you'd like an essential insight into the possibilities and key considerations when using new materials.

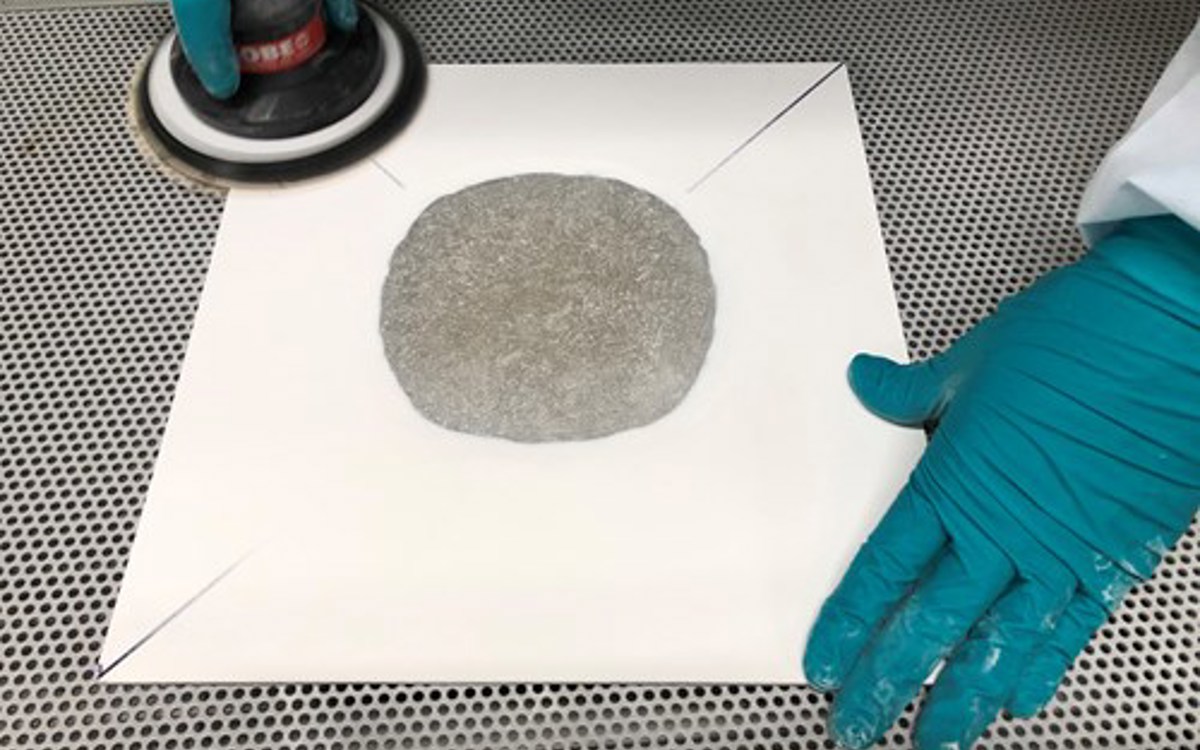

Whether you're working from original parts or creating your own mould tools, this course will give you the knowledge and practical skills to produce high quality mould tools and avoid common errors.

If you're looking to implement automated processes into your existing composite manufacturing activities this course will give you the knowledge you need to explore and assess techniques to take your production to the next level.

As an engineer who is currently responsible for measuring and inspecting metalics, and are now moving into the world of composites, this course will give you the tools and knowledge you need to ensure that you understand the different challenges composites present and the techniques they require.

If you have an engineering background, but are new to composites, a basic knowledge of their composition and manufacture is essential to begin your journey. Or, maybe you don't work with composites on a day-to-day basis, but you are working with suppliers, colleagues or customers who do, and being able to knowledgably engage with them is important.

Sustainability is a global priority with a huge drive for change. As a society, our passion for sustainability from a moral perspective has grown rapidly, and there are now strong zero carbon legislation targets mandated across industries in a bid to reduce their impact on the environment.

The Composite Assembly course is a practical hands on workshop that perfectly complements our Composite Joining Principles theory course.

Composite materials need to be carefully designed for assembly. They also need to be assembled in a certain way to maximise joint performance.

Events for your diary

Want to connect, collaborate, and engage with us? Mark your calendars for upcoming events where you can meet us in person or virtually.

The National Composites Centre is proud to be part of Materials Research Exchange (MRE2024). Kyle Pender, Advanced Research Engineer, will be presenting. We also invite you to visit our stand where you can speak to the team about our services and capabilities.

Tim Young, Head of Sustainability at the National Composites Centre, will be sharing insights on Composites Recycling at a seminar hosted by Bristol Composites Institute on Wednesday 1 May 2024 at 2:00 PM.

SAMPE 2024 is North America's premier advanced materials and process engineering conference and exhibition tradeshow. Happening in May 2024, NCC experts will be available throughout the conference to discuss your engineering needs.

Dr. Peter Giddings, Chief Engineer for Energy at the National Composites Centre, will be presenting at Frontiers of solid mechanics for the energy transition, held by the International Union for Theoretical and Applied Mechanics (IUTAM).

Experts from the National Composites Centre will be attending the 21st European Conference on Composite Materials (ECCM21) held from 2nd – 5th July 2024, in Nantes, France.

ICEC29/ICMC 2024 presents the latest research and state-of-the-art developments in all cryogenics areas, including superconductivity, cryocoolers, cryogenic materials, and applications. Rebecca Clark, NCC's Research Engineer will be available throughout the conference to discuss our cryogenic capabilities and services.

Themed “Advanced & Sustainable Composites”, discussions will focus on the challenging applications in composites encompassing advanced composites materials, their processes, research, and development. Sponsored by the NCC, our engineering experts will be available throughout the conference to discuss engineering challenges and solutions.

The trade fair focuses on how materials can facilitate transition in the energy sector, with cutting-edge technologies, materials, and solutions for the extraction, generation, storage and transmission of energy. NCC experts will be available throughout the event to share insights into transformative energy developments and discuss net zero solutions.

Join the NCC at the International Composites Summit (ICS), considered the single place to do the most cost effective and sustainable composites business in the UK, bringing together industry leaders, researchers, and innovators from across the composites sector.

Held alongside ICS, FPCC 2024 brings together leading academic and industry researchers and innovators in the construction and infrastructure industry to share and discuss recent developments and future perspectives in the application of fibre-reinforced polymer composites across the sector. NCC experts will be available throughout the conference to discuss your innovative engineering needs.