21 October 2021

Digital technologies are revolutionising how engineering works – but, as John Pattinson, from DETI partner Digital Catapult, argues, understanding how they can be used meaningfully isn’t always obvious. So what’s the solution?

The global engineering landscape is rapidly shifting. Ever-changing consumer demands, shorter product development times, faster routes to market, and the need for through-life product sustainability for some of the most complex products the world has ever seen, are now commonplace.

We’re also seeing supplier relationships becoming more important than ever – with companies looking to diversify or accelerate production while keeping costs down. And, on top of all of this, digital technologies are fundamentally changing the way engineers work.

The sector is hard pressed to work out what tools to use, what technologies to invest in and how to exploit vast quantities of data captured at every stage. The heat is on. But, in spite of its challenges, this new world also brings about an exciting transformation opportunity for the engineering sector, one that is underpinned by four trends: scrupulous testing, skills, servitisation and sustainability.

The value of industrial testbeds

We’ve come a long way since engineers were tied to their desks, drowning in paperwork. Now, vital data – on aspects from design and maintenance, to waste – can be generated in real-time or accessed remotely with the click of a button.

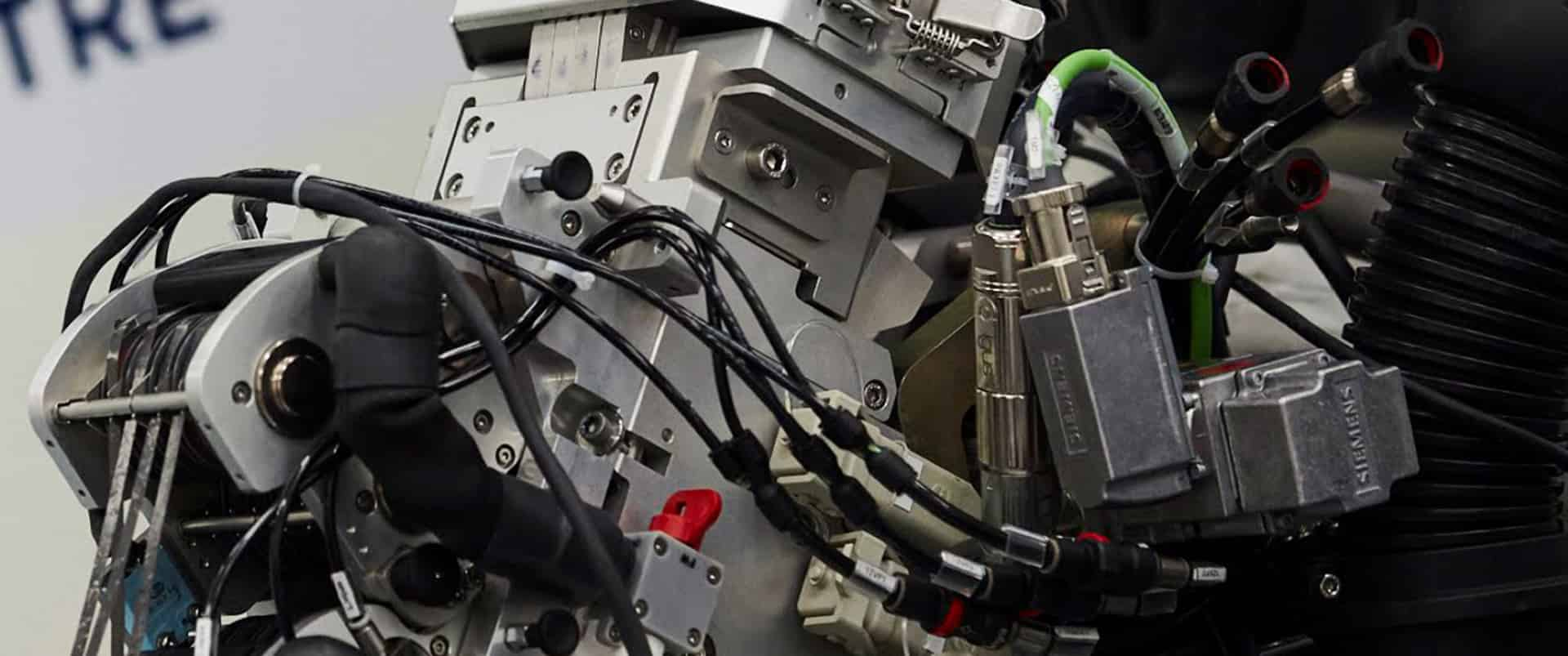

Exploring the best digital tools, developing an understanding of technologies to invest in and exploiting value from data generated throughout product lifecycles – most engineering businesses understand the fundamental need for these things. The grander challenge is locating the infrastructure, skills and expertise to do so in a cost-effective way. This is where Industrial testbeds – platforms for conducting rigorous, replicable and accurate testing of new tools and technologies – come into play.

Testbeds have historically played a large role in manufacturing prototype development – from aircraft engines, to software development. By bringing together collaborative design, connected manufacturing facilities and high-performance computing capabilities, industrial testbeds could provide industrial businesses with secure access to industry relevant data. This will enable organisations to develop powerful new tools and methods, and allow industry to engineer better products, more quickly, at lower cost.

Western Industrial Heritage, powered by 5G

5G-connected testbeds will be able to process data at hyper-fast speeds and enable businesses to test a larger variety of advanced digital technologies than ever before – from distributed ledger technologies like blockchain, to the Internet of Things.

Digital Catapult, for example, is part of a strategic, West of England Combined Authority programme called DETI – delivered by the National Composites Centre in partnership with industry. DETI is currently developing and maintaining a state-of the-art, 5G-enabled industrial testbed. Located in the West of England, an area rich in industrial history, it will be tailored to help organisations of all sizes to explore advanced digital tools and develop an understanding of their value.

The skills puzzle

Testbeds or no testbeds, the technological revolution in engineering is destined to fail if we don’t futureproof our workforces from a skills perspective. Engineering UK has estimated that UK engineering employers need to recruit 182,000 engineers annually to keep up with demand. Meanwhile, there is year-on-year decline in females entering the engineering and manufacturing sector, now making up only 10% of the workforce.

Sobering reading; as only with a robust and diverse pipeline of talent will the engineering sector be able to realise the fourth industrial revolution. As well as its testbed development work, DETI has initiated a comprehensive skills development programme to ensure the current and future workforce is digital-ready, and is establishing an engineering engagement hub for the West of England.

Initiatives like this – which not only offer engineering careers support to younger generations and widen aspirations for STEM careers, but also identify the skills needed to embed a digital culture throughout organisations and help focus solutions – will be central to successful digital transformation.

A shift to servitisation

The term servitisation has gained increased attention in the sector, with global disruptions like the pandemic and Brexit igniting the drive for manufacturers to diversify their income. The Advanced Services Group, a centre of excellence at Aston Business School, defines the term servitisation as transformation of a business to compete through a combination of services and products, rather than products alone.

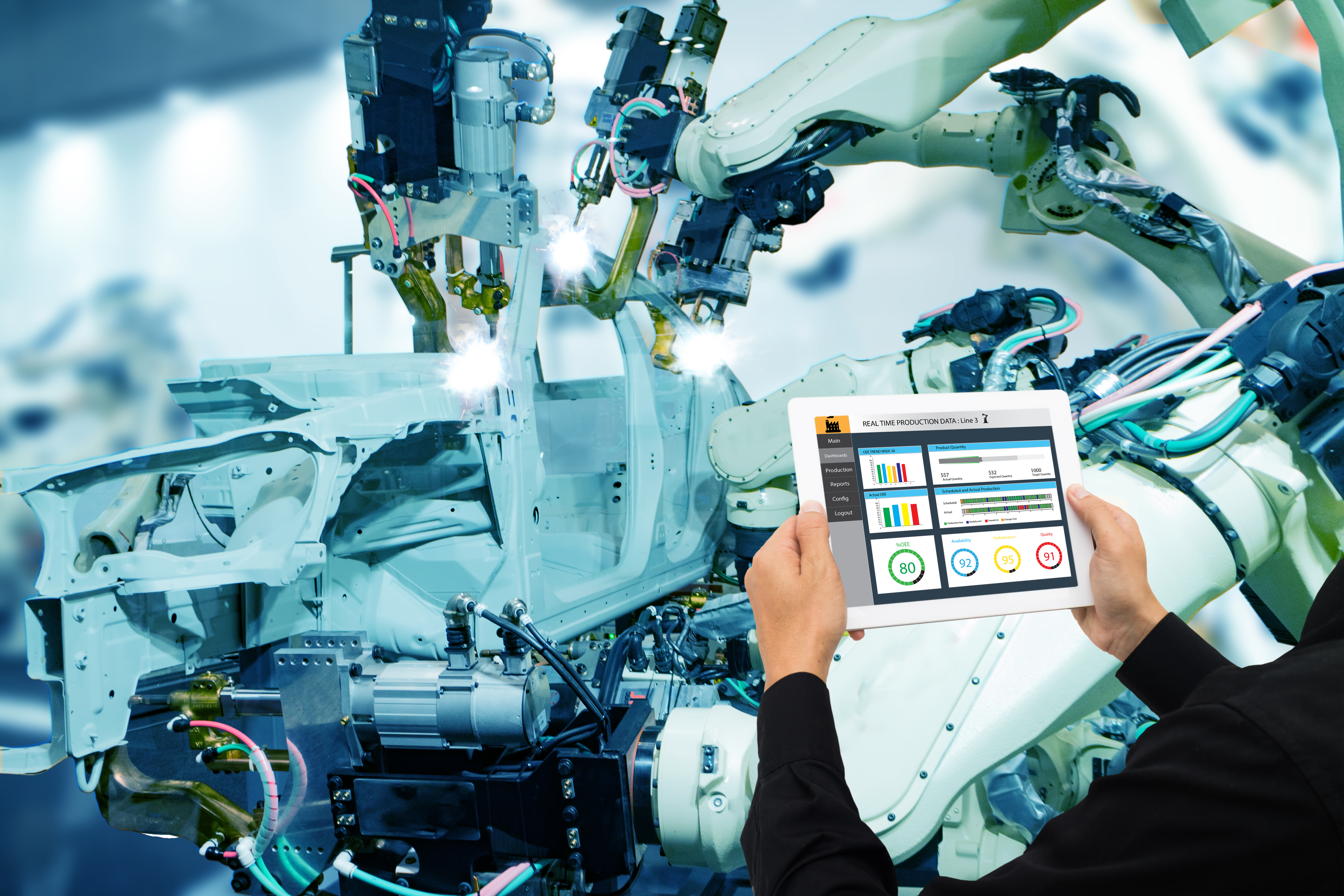

Engineering businesses can traditionally be reductionist in their strategy, focusing on cost, quality and delivery. While this approach is important for maintaining a healthy business, if taken as the sole focus, it can lead to a race to the bottom, and revenue stagnation. What does this mean in the context of digital? Well, technologies such as the Internet of Things, artificial intelligence and machine learning are supporting automation and deeper insights – driving commercial benefits beyond historic key performance indicators.

If the engineering sector is to continue growing, it must look not only at how data provides insights, but form an expansionist mindset focused also on generating new, innovative and difficult to imitate business models. This could be a manufacturing business, for example, introducing a maintenance offering for a certain product – using live data to identify any faults, and notifying engineers to replace them at the earliest possible stage. Then, taking this to the next level with outcome-based offerings, which involve working closely with customers to improve performance and taking a share of the savings achieved.

Sustainable futures

Looking ahead, with advanced digital technologies at our fingertips, we’re capable of transforming industrial processes in previously unimaginable ways. Take our net zero ambitions: Digital Catapult has developed a proof of concept for an application called the ‘Eco-meter’ for the National Composites Centre.

By streaming data on the equipment’s energy consumption, the eco-meter will allow us to visualise carbon footprint data on an hour-by-hour basis, as well as providing retrospective data to enable decision-making and planning. Whether it’s an aerospace engineer opting for a greener piece of equipment, or a manufacturing business taking targeted steps to improve a polluting process, we can all draw on data to help us make more informed decisions.

Destination digital

For the engineering sector, gaining deeper understanding of how these technologies can be used meaningfully isn’t simple. However, tapping into these overarching trends – the need to servitise, test technologies, build a skills pipelines and create more sustainable business models – is crucial to success. With testbeds, skills support, and the right expertise on hand, destination digital needn’t be so far away.

John Pattinson: Commercial Product Lead – IoT, Digital Catapult

John Pattinson is a digital business strategist and business developer, focused on working with partners and industry to accelerate the adoption of IoT technology. He has extensive experience in the Smart Factory/Industry 4.0 space, in developing and executing global strategies, bridging enterprise and operational technology, and laying out future technology and digital transformation roadmaps. For more information visit www.digicatapult.org.uk