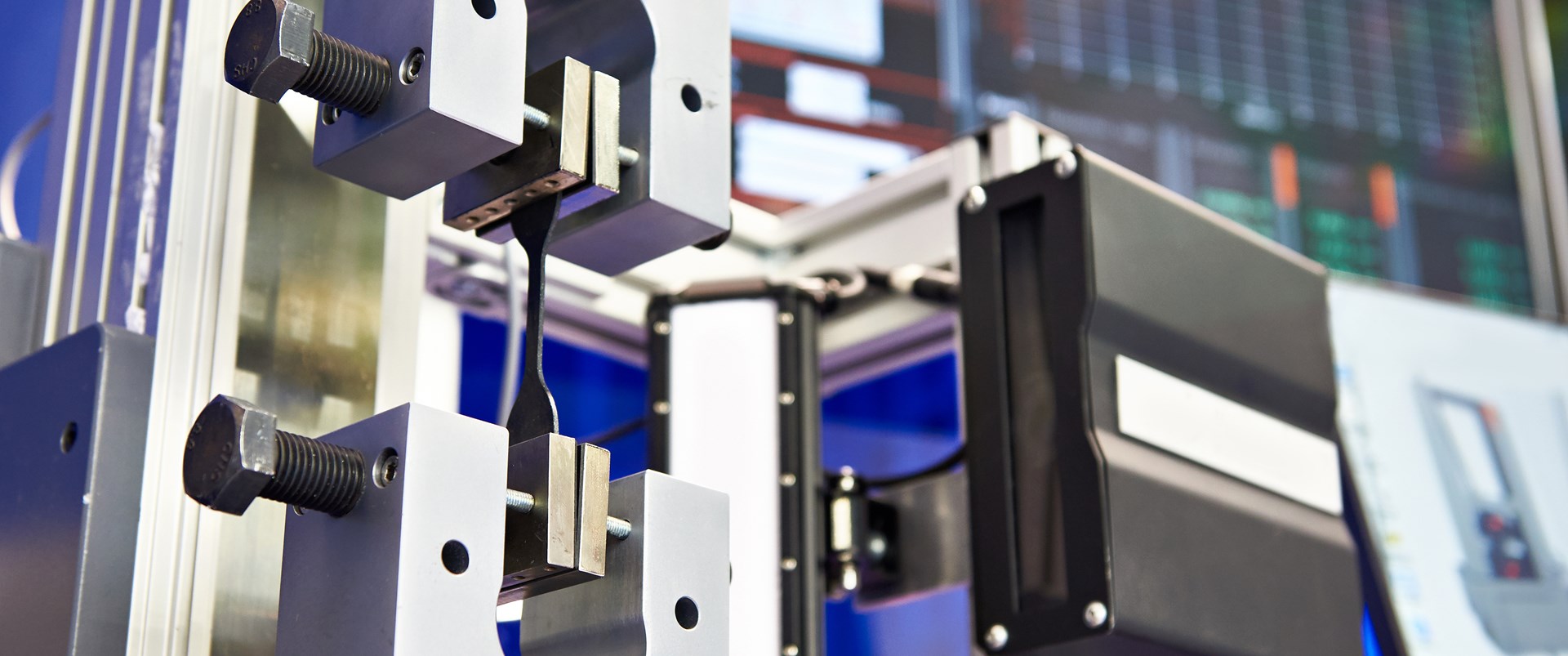

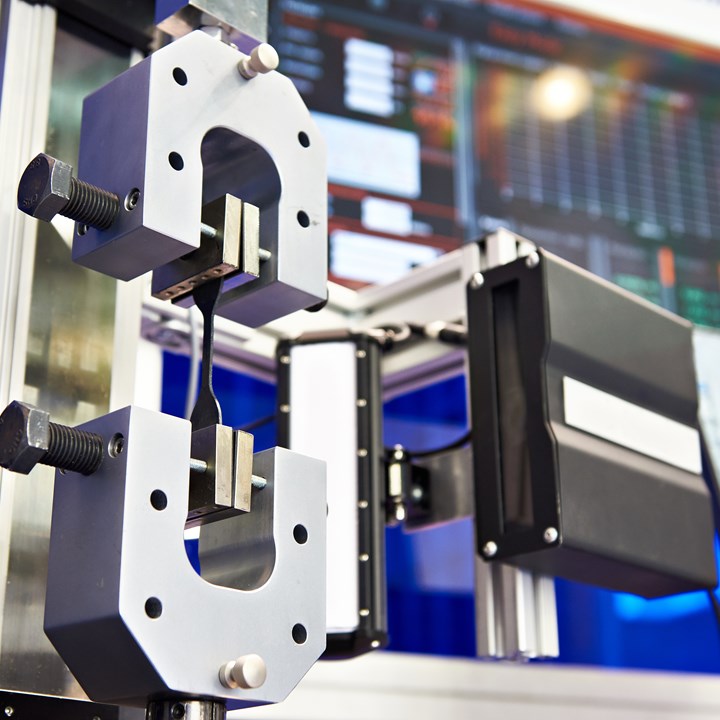

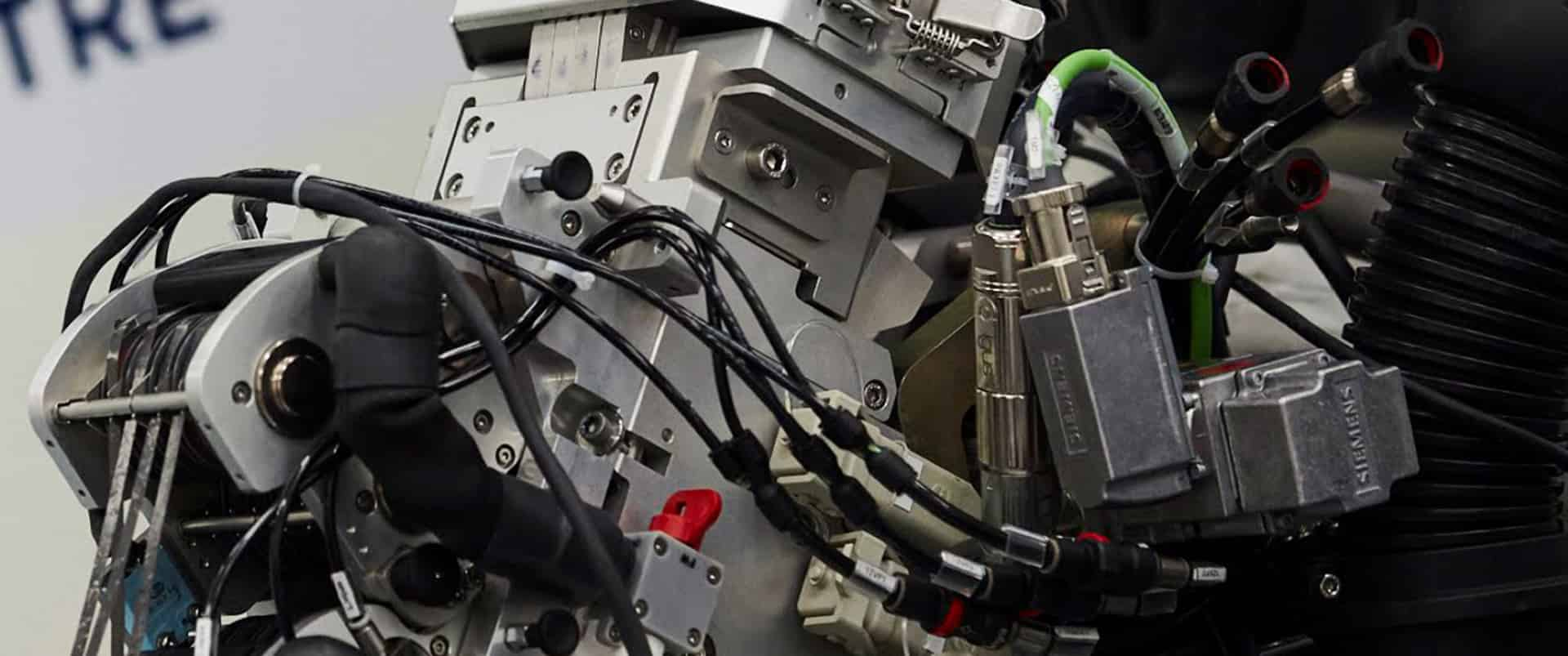

Testing design

Knowing what to test for, how to test and who can test can be challenging. Our experienced engineers possess the skills, knowledge and expertise to design test programmes that align with industry standards. Collaborating to deliver an efficient and effective delivery approach, we have experience in designing and delivering test pyramids with a wide range of sectors, applications and materials.

Beyond utilising established test methods and standards, we design and deliver bespoke test methods. Through our strong network of partnerships, we work with industry bodies to push the boundaries in state-of-the-art of testing to enable the innovations in new products and materials.