Driving circular solutions

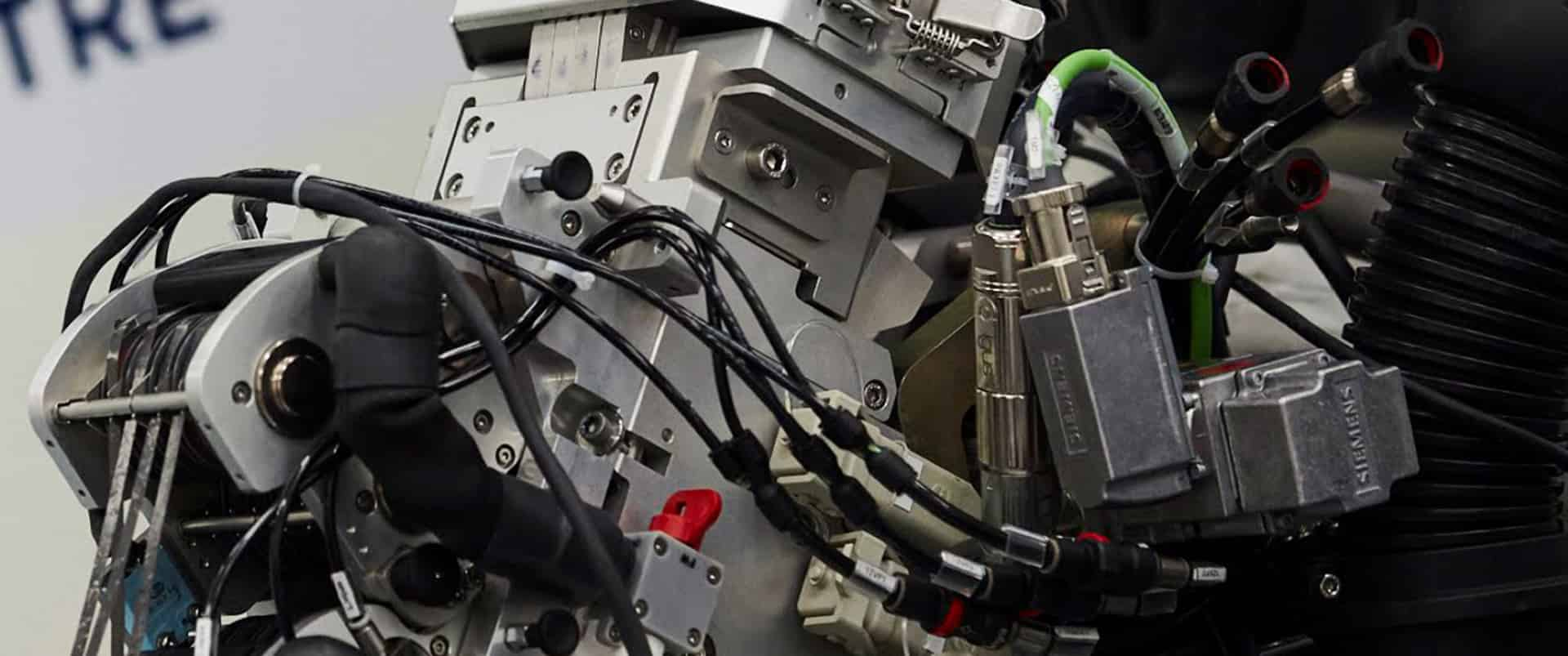

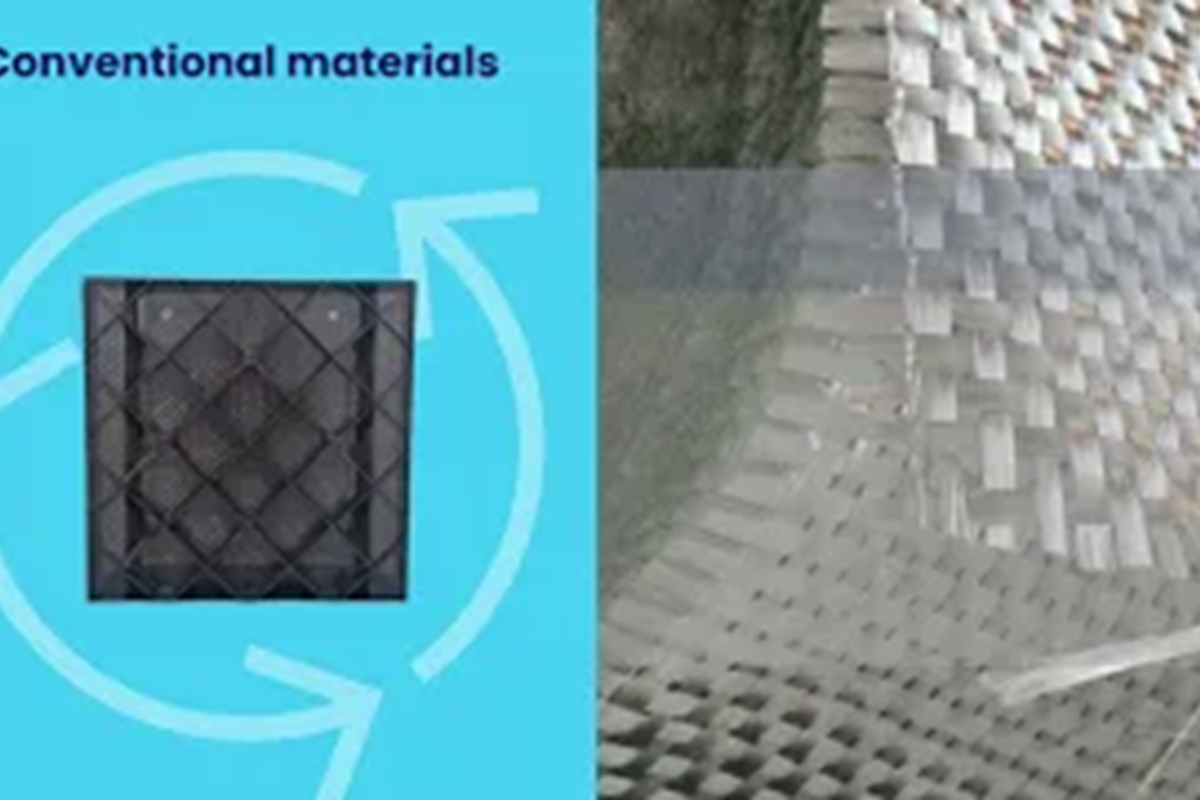

The overmoulder is being used to explore routes for companies to use low impact, circular materials in their products to redefine a new generation of products that will create a greener, cleaner future for all. Our engineers have successfully created two overmoulded composite parts. Both explore different approaches to integrating sustainable materials and circularity into the automotive industry.