28 April 2022

3 - 5 May 2022, Paris Nord Villepinte

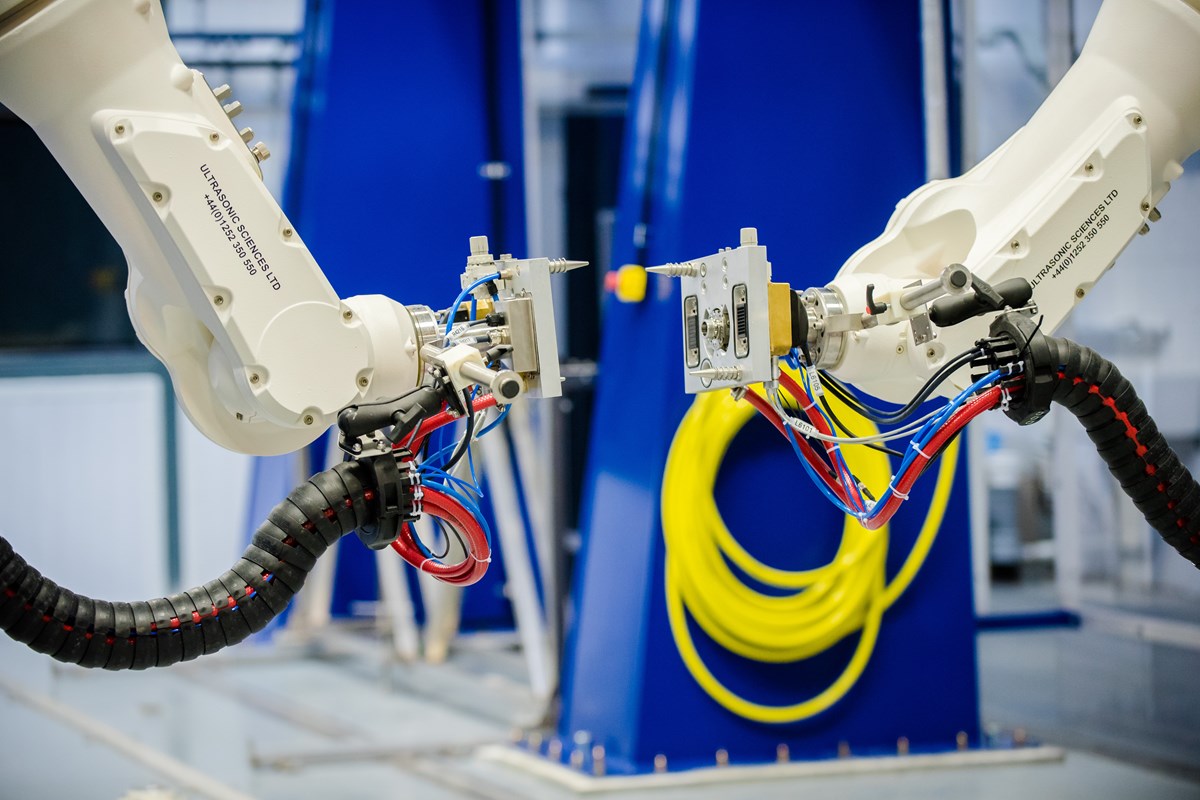

The National Composites Centre exhibited at JEC World, the leading international composites show, as part of the UK Pavilion with Composites UK, the Department of International Trade and 25 other UK companies.

Each year, JEC World gathers the whole value chain of composite materials in Paris, bringing together major stakeholders of the composites industry as well as innovative startups, academics, scientists and R&D leaders. For professionals from the various application sectors of composite materials, it is a unique showcase of what composites can offer, and an unlimited source of inspiration.

As part of the event, we made a number of announcements about the work we are doing to unlock innovation in the use of advanced composites, supporting industry to find new ways to design and make higher performing products more sustainably with less waste and that last longer.

Professor Tim Young, NCC's Head of Sustainable Technologies, was part of a panel discussing 'Rethinking composite materials manufacturing: The path to sustainable production'. Tim spoke to the audience about the major driving force toward innovation in sustainable manufacturing, the value of collaboration across the value chain and institutions, and the work of the NCC and the Sustainable Composites partnership.

Our announcements at JEC World 2022

-

-

Viable routes to recycling wind turbine blades found in NCC’s sustainable wind research programme

-

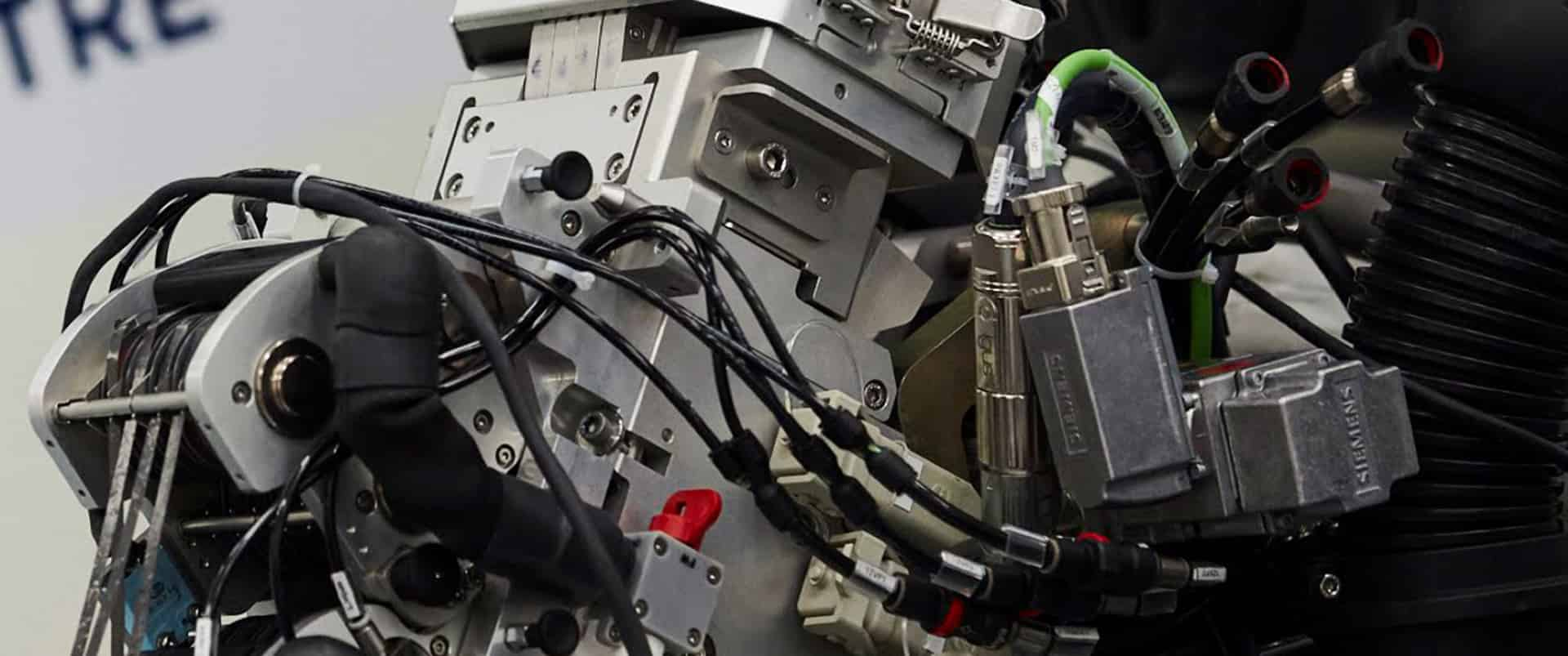

New digital design trial on a composite hydrogen pressure vessel five times faster